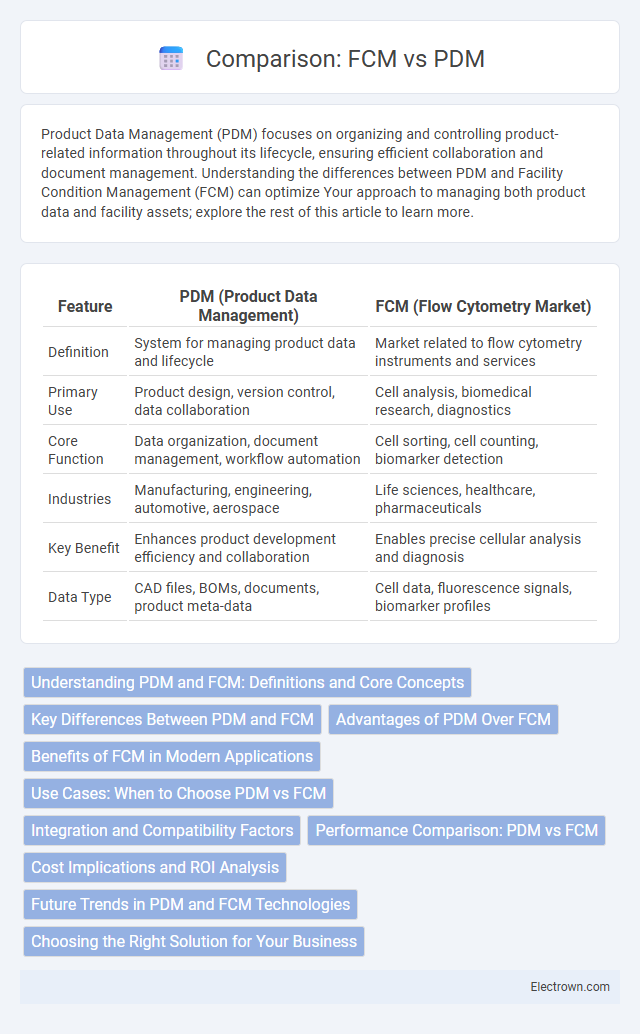

Product Data Management (PDM) focuses on organizing and controlling product-related information throughout its lifecycle, ensuring efficient collaboration and document management. Understanding the differences between PDM and Facility Condition Management (FCM) can optimize Your approach to managing both product data and facility assets; explore the rest of this article to learn more.

Table of Comparison

| Feature | PDM (Product Data Management) | FCM (Flow Cytometry Market) |

|---|---|---|

| Definition | System for managing product data and lifecycle | Market related to flow cytometry instruments and services |

| Primary Use | Product design, version control, data collaboration | Cell analysis, biomedical research, diagnostics |

| Core Function | Data organization, document management, workflow automation | Cell sorting, cell counting, biomarker detection |

| Industries | Manufacturing, engineering, automotive, aerospace | Life sciences, healthcare, pharmaceuticals |

| Key Benefit | Enhances product development efficiency and collaboration | Enables precise cellular analysis and diagnosis |

| Data Type | CAD files, BOMs, documents, product meta-data | Cell data, fluorescence signals, biomarker profiles |

Understanding PDM and FCM: Definitions and Core Concepts

Product Data Management (PDM) is a system that organizes and controls product-related information throughout the lifecycle to improve collaboration and efficiency. Feature-Chain Modeling (FCM) is a technique used in design and manufacturing to represent and manage interconnected features for enhanced product customization and flexibility. Both PDM and FCM streamline product development processes but focus on different aspects: data management versus feature integration.

Key Differences Between PDM and FCM

PDM (Product Data Management) centralizes and manages design data and engineering processes, enabling version control and collaboration within product development teams. FCM (Fleet Content Management) focuses on managing digital content distribution and updates across a fleet of devices, ensuring synchronized and up-to-date information delivery. Key differences lie in PDM's role in engineering data governance versus FCM's emphasis on content deployment and device management.

Advantages of PDM Over FCM

PDM offers superior robustness in cluster analysis by accommodating overlapping clusters and effectively handling uncertainty in data classification. It provides enhanced interpretability through the use of membership degrees, allowing for more nuanced data segmentation compared to the hard assignment approach of FCM. PDM also reduces the sensitivity to noise and outliers, resulting in more stable and reliable clustering outcomes in complex datasets.

Benefits of FCM in Modern Applications

FCM (Firebase Cloud Messaging) offers real-time, reliable, and scalable push notification delivery for modern applications, enhancing user engagement across Android, iOS, and web platforms. It supports advanced targeting features, including user segmentation and topic messaging, enabling personalized communication that drives retention. The seamless integration with Firebase's broader suite of development tools streamlines analytics and cloud functions, optimizing app performance and user experience.

Use Cases: When to Choose PDM vs FCM

PDM (Product Data Management) is ideal for managing complex product designs and engineering data in manufacturing environments requiring version control, change management, and collaboration across teams. FCM (Feature Control Management) excels in environments focused on feature-based manufacturing processes, such as CNC machining and additive manufacturing, where precise control over geometric features is critical. Choose PDM for comprehensive lifecycle management of product information, while FCM suits applications emphasizing feature-specific process optimization and quality control.

Integration and Compatibility Factors

PDM systems offer seamless integration with CAD software, enabling efficient management of design data and version control, crucial for engineering workflows. FCM platforms excel in compatibility with diverse enterprise resource planning (ERP) systems, facilitating smoother collaboration across manufacturing and supply chain operations. Selecting between PDM and FCM depends on the organization's need to prioritize integrated design data management or broader manufacturing process coordination.

Performance Comparison: PDM vs FCM

Performance comparison between Pulse Density Modulation (PDM) and Frequency-Shift Keying Modulation (FCM) reveals distinct advantages depending on application context. PDM offers higher resolution in digital audio conversion due to its oversampling and noise shaping techniques, resulting in superior signal-to-noise ratios and reduced quantization noise. FCM, however, excels in communication systems requiring robust frequency variation encoding, providing greater resilience to signal interference and bandwidth efficiency.

Cost Implications and ROI Analysis

PDM (Product Data Management) systems typically involve higher upfront costs due to complex implementation and licensing fees, whereas FCM (Financial Control Management) solutions often present lower initial expenses but may incur ongoing operational costs. Evaluating ROI for PDM focuses on long-term productivity gains and reduction in product development cycles, while FCM ROI is assessed through improved budget accuracy and enhanced financial compliance. Businesses must weigh immediate expenditure against strategic benefits, considering factors like scalability, integration capabilities, and impact on overall organizational efficiency.

Future Trends in PDM and FCM Technologies

Future trends in Product Data Management (PDM) and Feature Configuration Management (FCM) technologies emphasize integration with AI-driven analytics and cloud-based platforms to enhance real-time collaboration and decision-making. PDM systems are evolving to support digital twins and IoT data integration, improving lifecycle management and predictive maintenance capabilities. Your organization can leverage these advancements to streamline product development and adapt quickly to market changes.

Choosing the Right Solution for Your Business

Choosing the right solution between Product Data Management (PDM) and Flash Content Management (FCM) depends on your business needs. PDM excels at organizing and controlling product-related data, ensuring streamlined collaboration and version control for engineering and manufacturing teams. FCM focuses on managing and distributing digital content rapidly, making it ideal for businesses prioritizing dynamic media and customer engagement.

PDM vs FCM Infographic

electrown.com

electrown.com