CAN (Controller Area Network) is a robust vehicle bus standard designed for high-speed communication between microcontrollers without a host computer, while LIN (Local Interconnect Network) is a lower-cost, lower-speed protocol mainly used for simple, short-distance communication in automotive networks. Understanding the differences between CAN and LIN will help you choose the right communication protocol for your automotive or industrial application; explore the article to learn more about their features and applications.

Table of Comparison

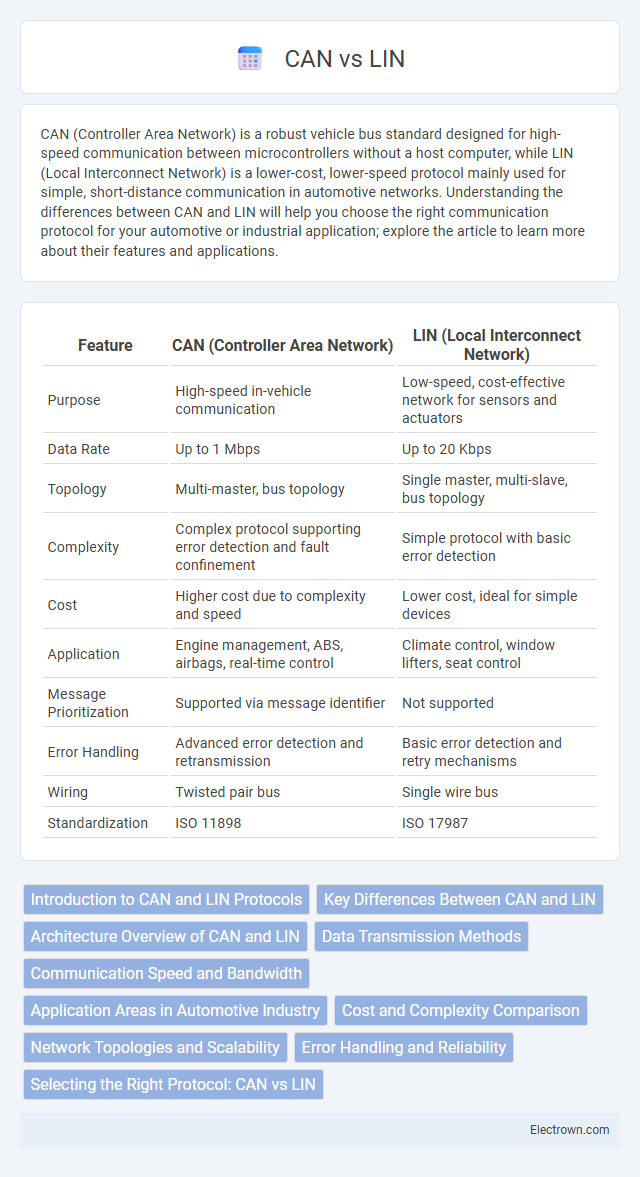

| Feature | CAN (Controller Area Network) | LIN (Local Interconnect Network) |

|---|---|---|

| Purpose | High-speed in-vehicle communication | Low-speed, cost-effective network for sensors and actuators |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Topology | Multi-master, bus topology | Single master, multi-slave, bus topology |

| Complexity | Complex protocol supporting error detection and fault confinement | Simple protocol with basic error detection |

| Cost | Higher cost due to complexity and speed | Lower cost, ideal for simple devices |

| Application | Engine management, ABS, airbags, real-time control | Climate control, window lifters, seat control |

| Message Prioritization | Supported via message identifier | Not supported |

| Error Handling | Advanced error detection and retransmission | Basic error detection and retry mechanisms |

| Wiring | Twisted pair bus | Single wire bus |

| Standardization | ISO 11898 | ISO 17987 |

Introduction to CAN and LIN Protocols

CAN (Controller Area Network) is a robust vehicle bus standard designed for real-time communication between microcontrollers without a host computer, widely used in automotive and industrial applications for reliable, high-speed data exchange. LIN (Local Interconnect Network) serves as a cost-effective, lower-speed communication protocol primarily for simpler vehicle networks, enabling control of non-critical components like door locks and climate control. You can optimize system performance by choosing CAN for complex, time-sensitive data tasks and LIN for straightforward, low-bandwidth applications.

Key Differences Between CAN and LIN

CAN (Controller Area Network) offers high-speed communication up to 1 Mbps, supporting complex, real-time data exchange in automotive and industrial systems, while LIN (Local Interconnect Network) operates at lower speeds around 20 Kbps, designed for simpler, cost-effective network applications like sensor and actuator communication. CAN uses a multi-master decentralized protocol allowing multiple nodes to transmit simultaneously with robust error handling, whereas LIN follows a single-master, multiple-slave architecture with simpler error management ideal for non-critical functions. Your choice between CAN and LIN depends on the required data rate, network complexity, and cost constraints of your vehicle or machinery system.

Architecture Overview of CAN and LIN

Controller Area Network (CAN) features a multi-master, message-oriented protocol designed for high-speed communication among microcontrollers and devices within a networked system, utilizing a robust two-wire differential signaling transmission. Local Interconnect Network (LIN) operates as a single-master, multiple-slave communication protocol optimized for low-speed, cost-effective applications with a single-wire serial communication architecture. CAN supports real-time data exchange with prioritized message arbitration, whereas LIN uses a simpler frame-based structure controlled by the master node for periodic and event-driven messaging.

Data Transmission Methods

CAN (Controller Area Network) utilizes a multi-master, message-oriented protocol allowing multiple nodes to communicate on the same bus with priority-based arbitration, enabling efficient and robust data transmission with speeds up to 1 Mbps. LIN (Local Interconnect Network) operates as a single-master, multiple-slave serial communication protocol designed for simpler, lower-cost applications with data rates up to 20 Kbps, using a master-slave communication method. The fundamental difference lies in CAN's event-driven message broadcast system versus LIN's time-triggered, master-controlled data frames.

Communication Speed and Bandwidth

CAN (Controller Area Network) offers higher communication speeds, typically up to 1 Mbps, providing robust data transmission for complex automotive and industrial networks. LIN (Local Interconnect Network) operates at lower speeds, generally maxing out around 20 Kbps, which suits simpler applications with limited bandwidth requirements. Your choice between CAN and LIN depends on the required data rate and network complexity, with CAN preferred for high-speed, high-bandwidth communication.

Application Areas in Automotive Industry

CAN (Controller Area Network) is widely used in automotive applications requiring high-speed data exchange and real-time control, such as engine management, antilock braking systems (ABS), and transmission control. LIN (Local Interconnect Network) is preferred for lower-speed communication in body electronics like window controls, seat adjustments, and interior lighting, offering a cost-effective solution for non-critical functions. Your vehicle's efficient operation depends on the seamless integration of CAN for complex systems and LIN for simpler, comfort-related features.

Cost and Complexity Comparison

CAN (Controller Area Network) systems generally present higher costs and complexity due to their robust error handling and faster data transfer rates, making them suitable for critical applications such as automotive safety systems. LIN (Local Interconnect Network) offers a more cost-effective and simpler solution, ideal for lower-speed, less critical communication tasks like controlling vehicle comfort features. Your choice depends on balancing budget constraints against the required network performance and reliability.

Network Topologies and Scalability

CAN networks typically use a bus topology that allows multiple nodes to communicate efficiently with low latency, making it highly scalable for complex automotive systems. LIN networks rely on a master-slave bus topology, which limits scalability due to a single master controlling up to 16 slave nodes, suitable for simpler applications with lower data rates. Your choice between CAN and LIN should consider the network size and scalability requirements, with CAN better suited for extensive distributed control systems.

Error Handling and Reliability

CAN (Controller Area Network) offers robust error handling with features like CRC checks, automatic retransmission, and error confinement, enhancing network reliability in automotive and industrial systems. LIN (Local Interconnect Network) uses a simpler error detection mechanism based on parity and checksums, which provides basic reliability but is less resilient to data corruption than CAN. CAN's advanced error detection and fault confinement support higher network stability and reduced data loss, making it preferable for safety-critical applications.

Selecting the Right Protocol: CAN vs LIN

Selecting the right protocol between CAN and LIN depends on your application's complexity and speed requirements. CAN offers high-speed communication and robust error handling, making it ideal for critical automotive systems requiring real-time data exchange. LIN suits simpler, lower-cost applications with slower speeds and less demanding communication needs, perfect for body electronics and comfort features.

CAN vs LIN Infographic

electrown.com

electrown.com