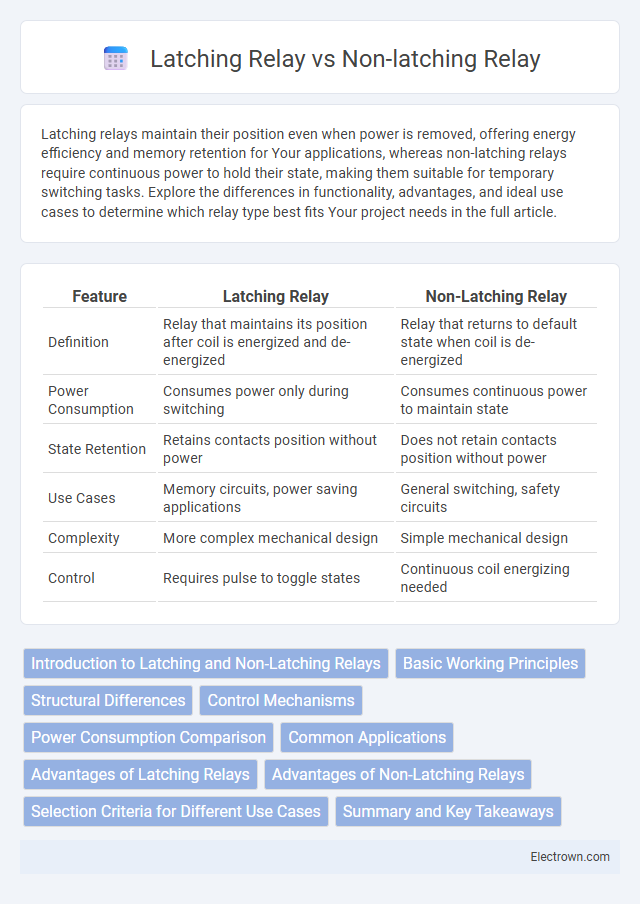

Latching relays maintain their position even when power is removed, offering energy efficiency and memory retention for Your applications, whereas non-latching relays require continuous power to hold their state, making them suitable for temporary switching tasks. Explore the differences in functionality, advantages, and ideal use cases to determine which relay type best fits Your project needs in the full article.

Table of Comparison

| Feature | Latching Relay | Non-Latching Relay |

|---|---|---|

| Definition | Relay that maintains its position after coil is energized and de-energized | Relay that returns to default state when coil is de-energized |

| Power Consumption | Consumes power only during switching | Consumes continuous power to maintain state |

| State Retention | Retains contacts position without power | Does not retain contacts position without power |

| Use Cases | Memory circuits, power saving applications | General switching, safety circuits |

| Complexity | More complex mechanical design | Simple mechanical design |

| Control | Requires pulse to toggle states | Continuous coil energizing needed |

Introduction to Latching and Non-Latching Relays

Latching relays maintain their position after the actuating voltage is removed, using a magnetic or mechanical latch, which makes them ideal for power-saving applications and memory retention in circuits. Non-latching relays return to their default state when the actuating voltage is removed, providing momentary switching suitable for applications requiring continuous power to hold the relay state. The choice between latching and non-latching relays depends on factors such as power consumption, application requirements, and the need for state retention.

Basic Working Principles

Latching relays maintain their position after being actuated, using a magnetic or mechanical latch, which allows them to save energy by not requiring continuous power to hold the state. Non-latching relays, also known as monostable relays, return to their default position once the actuating force is removed, relying on a spring to reset the contacts. Understanding your application's power consumption and switching requirements is essential when choosing between these two relay types.

Structural Differences

Latching relays feature a bistable mechanism, maintaining their position without continuous power by using a magnetic or mechanical latch, whereas non-latching relays rely on constant power to keep their contacts engaged. Structurally, latching relays often include a permanent magnet or a mechanical catch that holds the contacts in place after actuation, while non-latching types use a spring to return contacts to their default state when power is removed. Understanding these structural differences helps you select the appropriate relay for energy-efficient or fail-safe applications.

Control Mechanisms

Latching relays maintain their position after the control signal is removed, using a magnetic or mechanical latch mechanism that holds the contacts closed or open without continuous power. Non-latching relays require a continuous control voltage to keep the contacts energized and revert to their default state once power is cut. Control mechanisms for latching relays often involve a pulse signal to toggle states, whereas non-latching relays depend on sustained coil energization for activation.

Power Consumption Comparison

Latching relays consume power only during the switching operation, while non-latching relays require continuous power to maintain their state, resulting in higher energy usage. Due to their bistable nature, latching relays improve energy efficiency in applications where the relay state changes infrequently. Non-latching relays, commonly used where fast or frequent switching is needed, trade off increased power consumption for simpler control circuitry.

Common Applications

Latching relays are commonly used in energy-saving applications such as lighting control systems and remote switches, where maintaining the relay state without continuous power is critical. Non-latching relays find frequent use in automotive circuits, industrial machinery, and HVAC systems, where a continuous power supply is maintained to control devices through momentary switching. Both relay types offer distinct advantages depending on whether power retention or continuous activation is required in the application.

Advantages of Latching Relays

Latching relays offer significant energy efficiency by maintaining their state without continuous power supply, reducing overall power consumption in electrical systems. Their ability to retain position during power outages enhances reliability and prevents unintended resets, making them ideal for memory-critical applications. Moreover, latching relays produce less heat, which contributes to longer device lifespan and improved performance in temperature-sensitive environments.

Advantages of Non-Latching Relays

Non-latching relays offer rapid response times and simplified control circuits by requiring continuous power to maintain their state, which enhances reliability in applications needing active monitoring. Their automatic return to the default position upon power loss ensures fail-safe operation, minimizing the risk of unintended device states. These relays are cost-effective and widely available, making them suitable for circuits where frequent switching or momentary activation is necessary.

Selection Criteria for Different Use Cases

Latching relays are ideal for applications requiring power-saving operation and maintaining state without continuous coil energization, such as in memory circuits and energy-efficient systems. Non-latching relays are preferred for use cases demanding rapid switching and frequent coil activation, including industrial automation and motor control where reset capability is crucial. Selection depends on factors like power consumption, switching frequency, and holding state requirements specific to the application environment.

Summary and Key Takeaways

Latching relays maintain their contact position even after the control power is removed, making them ideal for applications where power consumption needs to be minimized or where the relay state must be preserved during power loss. Non-latching relays require continuous power to hold their position, which ensures quick response but increases energy use and may lose state during power outages. Understanding the differences between latching and non-latching relays helps you choose the right relay type for energy efficiency, reliability, and application-specific requirements.

Latching relay vs Non-latching relay Infographic

electrown.com

electrown.com