Touch buttons provide a sleek, modern interface with smooth, responsive controls ideal for contemporary devices, while mechanical buttons offer tactile feedback and durability favored in gaming and high-precision equipment. Discover which button type best suits Your needs by exploring their advantages and use cases further in this article.

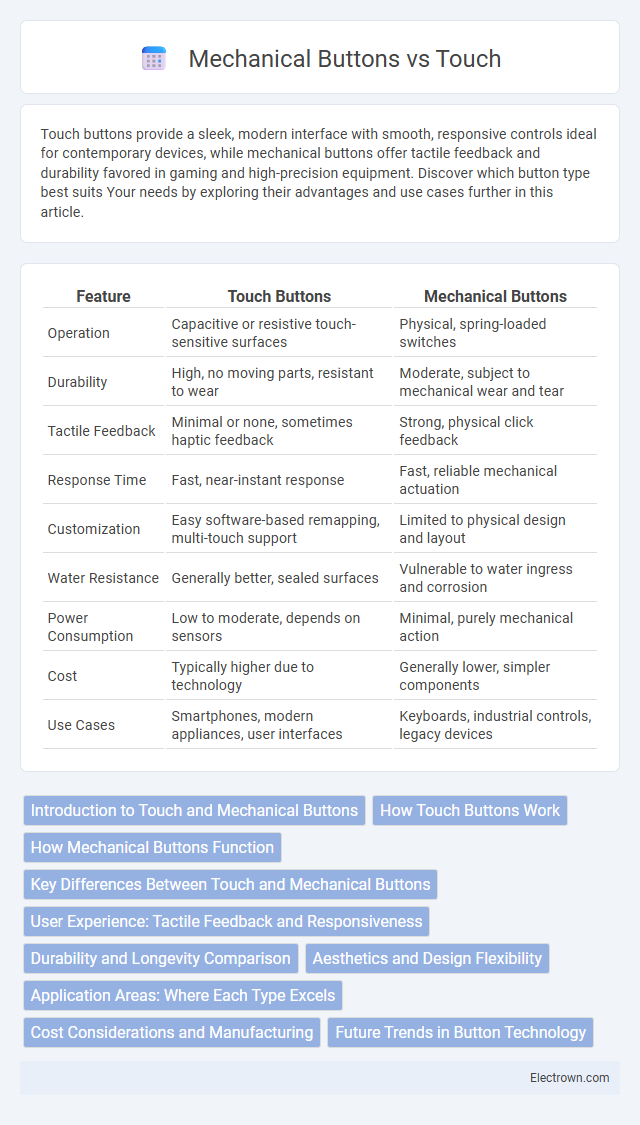

Table of Comparison

| Feature | Touch Buttons | Mechanical Buttons |

|---|---|---|

| Operation | Capacitive or resistive touch-sensitive surfaces | Physical, spring-loaded switches |

| Durability | High, no moving parts, resistant to wear | Moderate, subject to mechanical wear and tear |

| Tactile Feedback | Minimal or none, sometimes haptic feedback | Strong, physical click feedback |

| Response Time | Fast, near-instant response | Fast, reliable mechanical actuation |

| Customization | Easy software-based remapping, multi-touch support | Limited to physical design and layout |

| Water Resistance | Generally better, sealed surfaces | Vulnerable to water ingress and corrosion |

| Power Consumption | Low to moderate, depends on sensors | Minimal, purely mechanical action |

| Cost | Typically higher due to technology | Generally lower, simpler components |

| Use Cases | Smartphones, modern appliances, user interfaces | Keyboards, industrial controls, legacy devices |

Introduction to Touch and Mechanical Buttons

Touch buttons use capacitive or resistive sensing technology to detect your finger's presence, providing a sleek, modern interface with minimal physical wear. Mechanical buttons rely on physical switches with tactile feedback through mechanical parts, ensuring precise, reliable operation especially in demanding environments. Choosing between touch and mechanical buttons depends on your desired user experience, durability needs, and interface design preferences.

How Touch Buttons Work

Touch buttons operate by detecting changes in capacitance when a finger approaches or touches the sensor surface, enabling a response without physical movement. These sensors consist of conductive materials layered beneath a glass or plastic interface, creating an electric field that alters upon contact. This technology reduces mechanical wear, allowing for a more durable and sleek user interface compared to traditional mechanical buttons.

How Mechanical Buttons Function

Mechanical buttons operate by physically pressing a switch that closes an electrical circuit, sending a signal to the device to register input. Each press involves moving a spring-loaded mechanism or metal contact, creating tactile feedback that confirms activation. This technology ensures precise, reliable responses essential for various electronic devices and control interfaces.

Key Differences Between Touch and Mechanical Buttons

Touch buttons respond to electrical signals generated by the user's skin, offering silent operation and a sleek, flat surface ideal for modern devices requiring minimal physical feedback. Mechanical buttons rely on physical switches with tactile feedback triggered by pressing, providing precise actuation and durability preferred in gaming and industrial applications. Your choice depends on the need for responsiveness, durability, and user experience specific to the device's function.

User Experience: Tactile Feedback and Responsiveness

Mechanical buttons offer distinct tactile feedback that enhances user experience by providing physical confirmation of input, resulting in precise and satisfying responsiveness. Touch buttons rely on capacitive sensors, delivering a sleek interface but often lack the tangible sensation that aids in accuracy and reduces input errors. Users seeking reliable performance and high responsiveness typically prefer mechanical buttons for their tactile engagement and consistent feedback.

Durability and Longevity Comparison

Mechanical buttons typically offer superior durability due to their robust physical switches designed to withstand millions of presses, while touch buttons rely on sensitive capacitive sensors that can degrade with frequent use. Your device's longevity may benefit from mechanical buttons as they resist wear and environmental factors like dust and moisture more effectively. Touch buttons, though sleek and modern, often require more careful handling to maintain responsiveness over time.

Aesthetics and Design Flexibility

Touch buttons offer sleek, modern aesthetics with smooth surfaces that seamlessly blend into various device designs, enhancing your product's minimalist appeal. Mechanical buttons provide tactile feedback and a more classic, robust look but limit design flexibility due to their physical size and placement constraints. Choosing touch buttons allows greater freedom in customizing shapes, sizes, and layouts to complement innovative and futuristic designs.

Application Areas: Where Each Type Excels

Touch buttons excel in modern consumer electronics, smart appliances, and automotive infotainment systems due to their sleek design, ease of cleaning, and responsiveness to light touch. Mechanical buttons are preferred in industrial settings, medical devices, and outdoor equipment where durability, tactile feedback, and reliability under harsh conditions are critical. Your choice between touch and mechanical buttons should align with the specific operational environment and user interaction requirements to ensure optimal performance.

Cost Considerations and Manufacturing

Mechanical buttons generally incur higher manufacturing costs due to complexity in assembly and the need for durable materials, while touch buttons reduce expenses by using integrated circuits and fewer moving parts. Touch technology supports streamlined production processes and enables thinner device designs, lowering overall material and labor costs. Choosing between these options impacts your product's price point and manufacturing scalability based on cost efficiency and intended user experience.

Future Trends in Button Technology

Future trends in button technology are shifting towards advanced capacitive touch interfaces, offering seamless integration with IoT devices and enhanced user experiences through haptic feedback. Mechanical buttons continue to evolve with customizable, low-profile designs favored for durability and tactile precision, particularly in gaming and industrial applications. Your interaction with devices will increasingly blend touch sensitivity and mechanical reliability, promoting smarter, more responsive controls.

Touch vs Mechanical Buttons Infographic

electrown.com

electrown.com