SAW resonators offer high-frequency stability and low phase noise, making them ideal for applications requiring precise timing and filtering, while quartz crystals provide excellent frequency accuracy and long-term stability at lower costs. Discover how to choose the right component for your specific needs by exploring the key differences between SAW resonators and quartz crystals in the rest of this article.

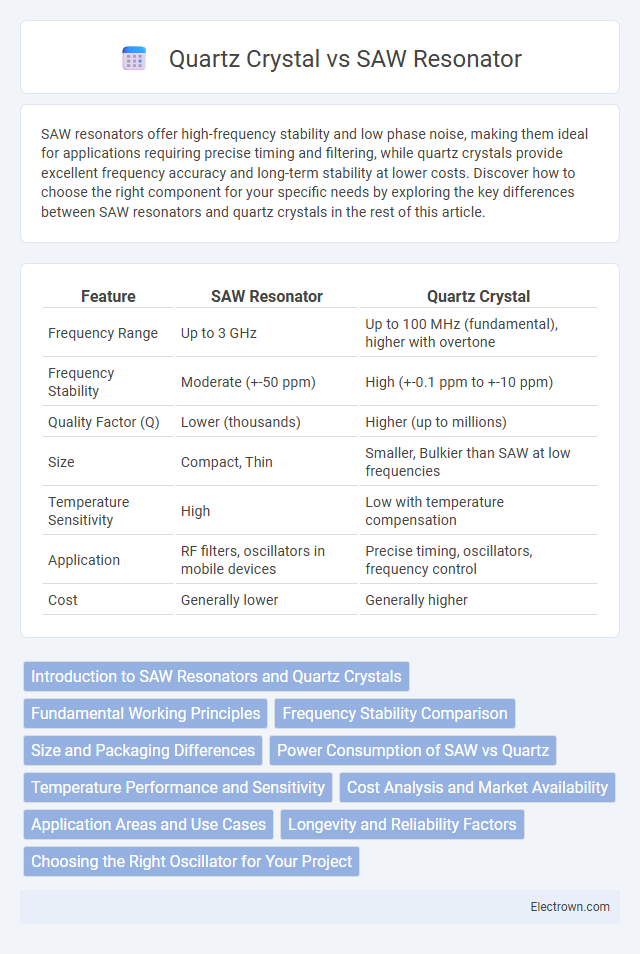

Table of Comparison

| Feature | SAW Resonator | Quartz Crystal |

|---|---|---|

| Frequency Range | Up to 3 GHz | Up to 100 MHz (fundamental), higher with overtone |

| Frequency Stability | Moderate (+-50 ppm) | High (+-0.1 ppm to +-10 ppm) |

| Quality Factor (Q) | Lower (thousands) | Higher (up to millions) |

| Size | Compact, Thin | Smaller, Bulkier than SAW at low frequencies |

| Temperature Sensitivity | High | Low with temperature compensation |

| Application | RF filters, oscillators in mobile devices | Precise timing, oscillators, frequency control |

| Cost | Generally lower | Generally higher |

Introduction to SAW Resonators and Quartz Crystals

SAW resonators utilize surface acoustic waves to filter and stabilize frequencies, making them ideal for high-frequency and RF applications. Quartz crystals rely on the piezoelectric effect within quartz material for precise frequency control, commonly used in oscillators and clocks. Both components are essential in electronics for frequency selection, but SAW resonators excel in compact, high-frequency environments while quartz crystals provide superior frequency stability and accuracy.

Fundamental Working Principles

SAW resonators utilize surface acoustic waves propagated along a piezoelectric substrate to filter and stabilize frequencies, whereas quartz crystals rely on the mechanical vibration of a quartz crystal lattice to produce precise oscillations. The piezoelectric effect in both devices converts electrical signals into mechanical vibrations, but SAW resonators operate primarily through wave propagation on the surface, offering compact size and high-frequency performance. Understanding these fundamental working principles helps you select the right component for applications requiring frequency control and signal processing.

Frequency Stability Comparison

SAW resonators offer excellent frequency stability over a wide temperature range due to their surface acoustic wave propagation characteristics, making them ideal for applications requiring consistent performance in varying environmental conditions. Quartz crystals provide superior long-term frequency stability with minimal aging effects, ensuring precise oscillation for high-accuracy timing devices. Your choice depends on whether you prioritize temperature resilience or ultra-low frequency drift in critical frequency control applications.

Size and Packaging Differences

SAW resonators are generally smaller and offer more compact packaging compared to quartz crystals, making them ideal for space-constrained applications. Quartz crystals require bulkier, often hermetically sealed packaging to maintain frequency stability and protect against environmental factors. Your choice between these components will depend on the size requirements and packaging constraints of your electronic device.

Power Consumption of SAW vs Quartz

SAW resonators typically consume less power than quartz crystal oscillators due to their simpler construction and lower drive level requirements. Quartz crystals require higher power levels to maintain stable oscillation, especially at higher frequencies, which can increase overall energy usage in circuits. This makes SAW resonators more suitable for low-power applications such as portable and battery-operated devices.

Temperature Performance and Sensitivity

SAW resonators exhibit superior temperature performance with minimal frequency drift due to their low temperature coefficient, making them ideal for applications requiring stable operation across wide temperature ranges. Quartz crystals, although highly sensitive and stable in controlled environments, can experience significant frequency variations when exposed to temperature fluctuations. Your choice between SAW resonators and quartz crystals should consider the operational temperature range and sensitivity requirements of your specific application.

Cost Analysis and Market Availability

SAW resonators generally offer a lower cost compared to quartz crystals due to simpler manufacturing processes and smaller material usage, making them ideal for cost-sensitive applications. Quartz crystals dominate high-precision frequency control markets because of their superior stability and availability in a wide range of frequency options. Market availability favors quartz crystals with established supply chains and mass production, while SAW resonators are more niche but rapidly gaining presence in consumer electronics.

Application Areas and Use Cases

SAW resonators excel in high-frequency applications such as RF filters in mobile communications, GPS modules, and wireless devices due to their compact size and excellent performance at VHF and UHF bands. Quartz crystals are widely used in timing and frequency control for microcontrollers, clocks, and industrial automation because of their superior stability and precision at lower frequencies. Your choice depends on the application's frequency range and stability requirements, with SAW resonators favored for high-frequency signal processing and quartz crystals ideal for accurate timekeeping and low-frequency oscillation.

Longevity and Reliability Factors

SAW resonators offer enhanced longevity due to their solid-state design with no moving parts, reducing mechanical wear and enhancing reliability in high-vibration environments. Quartz crystals, while providing precise frequency stability, are more susceptible to aging effects and environmental stress, which can lead to frequency drift over time. Industrial applications demanding durable and stable frequency references often favor SAW resonators for their superior resistance to shock and thermal variations.

Choosing the Right Oscillator for Your Project

SAW resonators offer high-frequency stability and low phase noise ideal for wireless communication and RF applications, while quartz crystals provide exceptional frequency accuracy and long-term stability suitable for precision timing and control systems. Selecting the right oscillator depends on factors like frequency range, temperature tolerance, size constraints, and environmental robustness. Engineers prioritize SAW resonators for compact, high-frequency circuits, whereas quartz crystals are preferred for applications demanding superior stability and low aging effects.

SAW Resonator vs Quartz Crystal Infographic

electrown.com

electrown.com