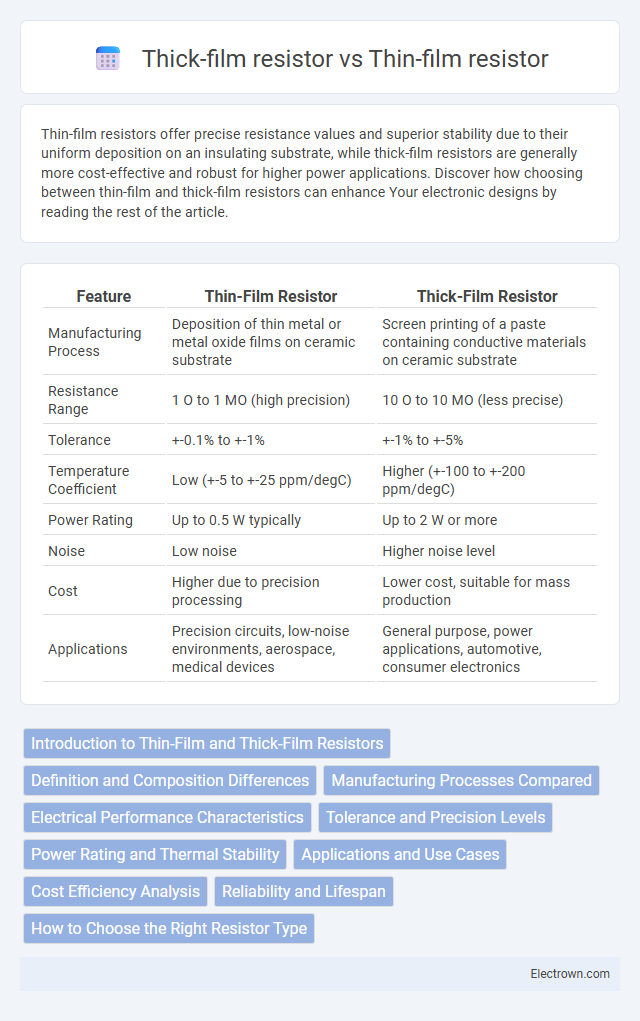

Thin-film resistors offer precise resistance values and superior stability due to their uniform deposition on an insulating substrate, while thick-film resistors are generally more cost-effective and robust for higher power applications. Discover how choosing between thin-film and thick-film resistors can enhance Your electronic designs by reading the rest of the article.

Table of Comparison

| Feature | Thin-Film Resistor | Thick-Film Resistor |

|---|---|---|

| Manufacturing Process | Deposition of thin metal or metal oxide films on ceramic substrate | Screen printing of a paste containing conductive materials on ceramic substrate |

| Resistance Range | 1 O to 1 MO (high precision) | 10 O to 10 MO (less precise) |

| Tolerance | +-0.1% to +-1% | +-1% to +-5% |

| Temperature Coefficient | Low (+-5 to +-25 ppm/degC) | Higher (+-100 to +-200 ppm/degC) |

| Power Rating | Up to 0.5 W typically | Up to 2 W or more |

| Noise | Low noise | Higher noise level |

| Cost | Higher due to precision processing | Lower cost, suitable for mass production |

| Applications | Precision circuits, low-noise environments, aerospace, medical devices | General purpose, power applications, automotive, consumer electronics |

Introduction to Thin-Film and Thick-Film Resistors

Thin-film resistors utilize a thin metal layer deposited on an insulating substrate, offering precise resistance values and superior stability for high-frequency applications. Thick-film resistors are created by screen-printing a resistive paste onto a ceramic base, providing cost-effective, high-power capabilities with wider tolerance ranges. Choosing between thin-film and thick-film resistors depends on your specific requirements for accuracy, durability, and cost efficiency.

Definition and Composition Differences

Thin-film resistors consist of a very thin layer of resistive metal deposited on an insulated substrate using sputtering or evaporation, offering high precision and stability. Thick-film resistors are made by screen printing a paste of conductive and resistive materials onto a ceramic substrate, which results in a more robust but less precise component. Your choice depends on the required tolerance, stability, and application environment, as thin-film resistors excel in accuracy while thick-film resistors provide cost-effective durability.

Manufacturing Processes Compared

Thin-film resistors are manufactured using physical vapor deposition techniques, such as sputtering or evaporation, to apply a thin metallic layer onto an insulating substrate, followed by photolithographic patterning for precise resistance values and tight tolerances. Thick-film resistors are produced by screen-printing a paste containing conductive particles, glass frit, and organic binder onto a ceramic base, then firing at high temperatures to fuse the materials and form a resistive element. The thin-film process offers higher precision and stability, while the thick-film process is more cost-effective for large-volume production with greater power handling capacity.

Electrical Performance Characteristics

Thin-film resistors exhibit superior electrical performance with low noise, high stability, and tight tolerance compared to thick-film resistors, making them ideal for precision applications. Your circuit benefits from better temperature coefficient and lower parasitic inductance in thin-film types, enhancing signal integrity in high-frequency environments. Thick-film resistors typically offer higher power dissipation but have greater resistance variability and noise levels.

Tolerance and Precision Levels

Thin-film resistors offer superior tolerance and precision levels, often achieving +-0.1% or better, making them ideal for high-accuracy applications. Thick-film resistors typically provide tolerance values around +-1%, which suits general-purpose circuits but limits precision-critical uses. Your choice depends on whether tight tolerance and low temperature coefficient are crucial for your design.

Power Rating and Thermal Stability

Thin-film resistors offer superior thermal stability and lower temperature coefficients, ensuring consistent performance under varying temperatures, making them ideal for precision applications. Their power rating typically ranges from 0.1W to 0.5W, which is lower compared to thick-film resistors that can handle power ratings up to several watts, suitable for higher power dissipation needs. Choosing the right type depends on your application's power requirements and the need for temperature resilience, with thin-film providing enhanced accuracy and thick-film offering greater power handling.

Applications and Use Cases

Thin-film resistors are preferred in precision electronics such as medical devices, aerospace instruments, and high-frequency circuits due to their superior accuracy, stability, and low noise performance. Thick-film resistors, favored in power electronics, automotive applications, and general-purpose circuit boards, offer higher power dissipation and cost-effectiveness for bulk manufacturing. Both types are integral to modern electronics, with thin-film suited for high-precision, low-power scenarios, while thick-film excels in robust, high-power environments.

Cost Efficiency Analysis

Thin-film resistors offer higher precision and stability but generally come at a higher manufacturing cost compared to thick-film resistors, which are more cost-efficient for large-scale production. Thick-film resistors utilize screen-printing techniques on ceramic substrates, making them economically favorable for applications requiring moderate accuracy. Cost efficiency analysis favors thick-film resistors in volume-driven projects, whereas thin-film resistors justify their expense in high-performance, low-tolerance environments.

Reliability and Lifespan

Thin-film resistors exhibit higher reliability and longer lifespan due to their precise construction, stable materials, and superior tolerance to thermal stress and environmental factors. Thick-film resistors, while cost-effective, typically have shorter lifespans and lower reliability because of their porous structure, which is more susceptible to moisture and mechanical wear. You can ensure better performance and durability in critical applications by selecting thin-film resistors.

How to Choose the Right Resistor Type

Choosing between thin-film and thick-film resistors depends on application requirements such as precision, power rating, and cost. Thin-film resistors offer superior accuracy and stability for high-frequency or low-noise circuits, making them ideal for precision instrumentation. Thick-film resistors provide higher power dissipation and cost-effectiveness, suitable for general-purpose applications with less stringent tolerance demands.

Thin-film resistor vs thick-film resistor Infographic

electrown.com

electrown.com