Point-to-point wiring offers direct connections between components, reducing interference and allowing easy modifications, while PCB wiring provides a compact, reliable, and scalable solution ideal for complex circuits. Explore the rest of the article to understand which method suits your electronic project best.

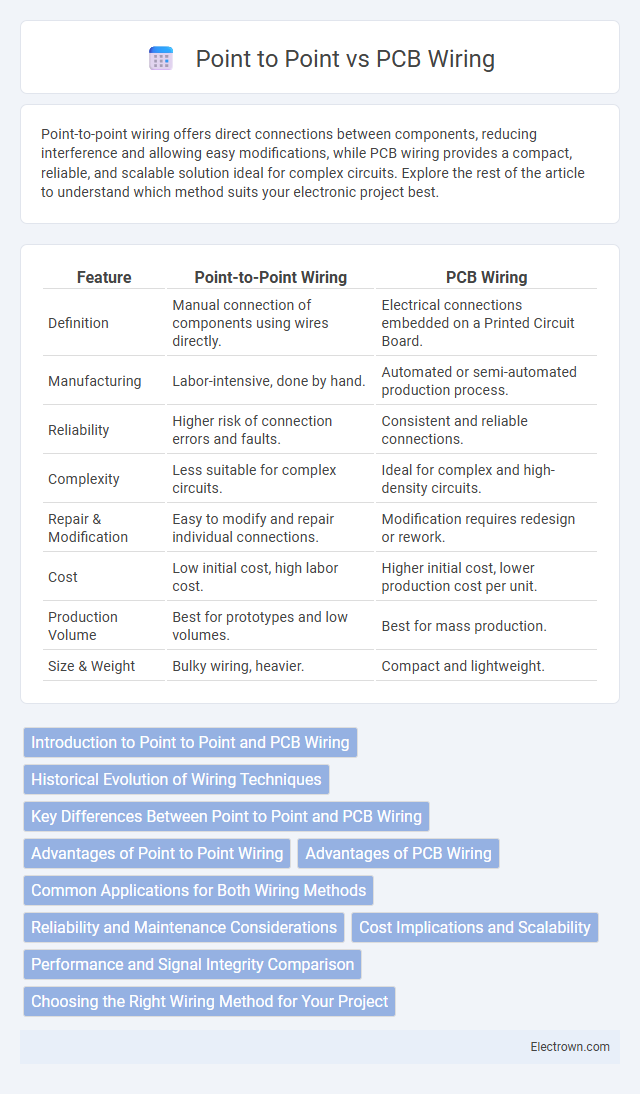

Table of Comparison

| Feature | Point-to-Point Wiring | PCB Wiring |

|---|---|---|

| Definition | Manual connection of components using wires directly. | Electrical connections embedded on a Printed Circuit Board. |

| Manufacturing | Labor-intensive, done by hand. | Automated or semi-automated production process. |

| Reliability | Higher risk of connection errors and faults. | Consistent and reliable connections. |

| Complexity | Less suitable for complex circuits. | Ideal for complex and high-density circuits. |

| Repair & Modification | Easy to modify and repair individual connections. | Modification requires redesign or rework. |

| Cost | Low initial cost, high labor cost. | Higher initial cost, lower production cost per unit. |

| Production Volume | Best for prototypes and low volumes. | Best for mass production. |

| Size & Weight | Bulky wiring, heavier. | Compact and lightweight. |

Introduction to Point to Point and PCB Wiring

Point to point wiring involves connecting individual components directly using wires, offering flexibility in custom or low-volume electronic assemblies. PCB wiring, or Printed Circuit Board wiring, uses etched copper tracks on a substrate to interconnect components, enabling high-density, reliable, and repeatable circuit designs. Your choice between these methods depends on factors like production scale, complexity, and durability requirements.

Historical Evolution of Wiring Techniques

Point-to-point wiring originated in early electronic devices, characterized by direct connections between components, offering simplicity but limiting scalability. The introduction of printed circuit boards (PCBs) revolutionized wiring by enabling compact layouts, improved reliability, and automated manufacturing processes. Your choice between these techniques reflects the balance between traditional craftsmanship and modern efficiency in electronic assembly.

Key Differences Between Point to Point and PCB Wiring

Point to point wiring involves manually connecting individual components using wires, offering flexibility and easier modifications but increasing the risk of wiring errors and inconsistent performance. PCB wiring uses a printed circuit board to create fixed conductive paths, ensuring reliable, repeatable connections and compact design while requiring precise manufacturing processes. Key differences include assembly complexity, durability, and scalability, with point to point favored in custom or vintage electronics and PCBs dominating modern mass production.

Advantages of Point to Point Wiring

Point to point wiring offers superior durability and ease of repair compared to PCB wiring, making it ideal for vintage audio equipment and custom electronics. This method allows for straightforward component replacement and modification without the need for specialized tools or extensive desoldering. Its flexibility also reduces the risk of circuit failure caused by PCB trace damage or manufacturing defects.

Advantages of PCB Wiring

PCB wiring offers significant advantages including higher reliability due to reduced risk of loose connections and consistent trace quality. It enables compact, organized circuit layouts that save space and improve signal integrity, resulting in better overall performance. Your designs benefit from easier scalability and automated manufacturing, which reduce production time and costs compared to point-to-point wiring.

Common Applications for Both Wiring Methods

Point-to-point wiring is commonly used in vintage audio equipment, high-end guitar amplifiers, and custom electronic projects where precise manual connections are preferred. PCB wiring dominates in mass-produced consumer electronics, computer hardware, and automotive control systems due to its efficiency and consistency in complex circuit designs. Your choice between these methods depends on the application's scale, required reliability, and level of customization.

Reliability and Maintenance Considerations

Point-to-point wiring offers higher reliability in high-current and vibration-prone applications due to its direct connections and reduced risk of trace damage compared to PCB wiring. Maintenance for point-to-point systems is often easier since individual components and wires can be inspected, replaced, or repaired without desoldering, whereas PCB repairs may require specialized equipment to fix broken traces or damaged pads. PCB wiring provides consistent electrical performance and compact design but can suffer from reliability issues such as cracked traces or cold solder joints, complicating maintenance efforts in field conditions.

Cost Implications and Scalability

Point-to-point wiring often incurs higher labor costs due to manual assembly, limiting cost efficiency for large-scale production; conversely, PCB wiring reduces unit cost as automated processes enable mass manufacturing. Scalability favors PCB wiring, with consistent quality and faster turnaround times supporting complex designs and volume increases, whereas point-to-point systems can become impractical and error-prone as complexity grows. Your choice impacts budget and scalability, with PCBs providing optimized solutions for expansion and cost control in modern electronics.

Performance and Signal Integrity Comparison

Point-to-point wiring offers shorter, more direct connections that reduce parasitic capacitance and inductance, enhancing signal integrity in high-frequency circuits. PCB wiring provides consistent trace geometry and controlled impedance, which is crucial for maintaining performance in complex, high-speed digital systems. Comparing both, point-to-point wiring excels in simplicity and low noise for analog applications, while PCB wiring ensures reliability and repeatability essential for modern electronic devices.

Choosing the Right Wiring Method for Your Project

Choosing the right wiring method for your project depends on factors like complexity, reliability, and production volume. Point-to-point wiring offers flexibility and easy modification for prototypes or low-volume builds, while PCB wiring provides durability, consistent performance, and scalability in mass production. Evaluate your project requirements to optimize wiring efficiency and ensure long-term functionality.

point to point vs pcb wiring Infographic

electrown.com

electrown.com