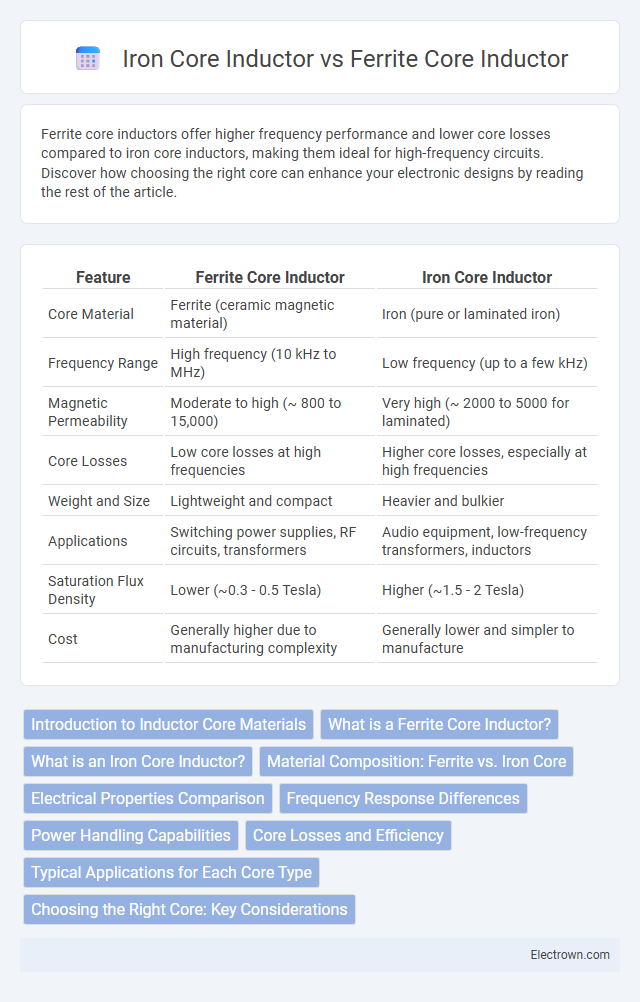

Ferrite core inductors offer higher frequency performance and lower core losses compared to iron core inductors, making them ideal for high-frequency circuits. Discover how choosing the right core can enhance your electronic designs by reading the rest of the article.

Table of Comparison

| Feature | Ferrite Core Inductor | Iron Core Inductor |

|---|---|---|

| Core Material | Ferrite (ceramic magnetic material) | Iron (pure or laminated iron) |

| Frequency Range | High frequency (10 kHz to MHz) | Low frequency (up to a few kHz) |

| Magnetic Permeability | Moderate to high (~ 800 to 15,000) | Very high (~ 2000 to 5000 for laminated) |

| Core Losses | Low core losses at high frequencies | Higher core losses, especially at high frequencies |

| Weight and Size | Lightweight and compact | Heavier and bulkier |

| Applications | Switching power supplies, RF circuits, transformers | Audio equipment, low-frequency transformers, inductors |

| Saturation Flux Density | Lower (~0.3 - 0.5 Tesla) | Higher (~1.5 - 2 Tesla) |

| Cost | Generally higher due to manufacturing complexity | Generally lower and simpler to manufacture |

Introduction to Inductor Core Materials

Ferrite core inductors offer high magnetic permeability and low eddy current losses, making them ideal for high-frequency applications such as switching power supplies and RF circuits. Iron core inductors provide higher magnetic saturation and are best suited for low-frequency, high-current environments like transformers and audio equipment. Choosing the right core material impacts your inductor's efficiency, size, and frequency response, ensuring optimal performance for your specific application.

What is a Ferrite Core Inductor?

A ferrite core inductor uses a magnetic core made of ferrite material, which is a ceramic compound composed of iron oxide mixed with other metals. This type of core minimizes eddy current losses and provides high magnetic permeability, making it ideal for high-frequency applications. Your circuits benefit from improved efficiency and reduced electromagnetic interference compared to traditional iron core inductors.

What is an Iron Core Inductor?

An iron core inductor features a core made of laminated iron or steel, which significantly increases its magnetic permeability compared to air core inductors, enhancing inductance and energy storage. This core type is commonly used in power applications requiring high inductance and current handling, such as transformers and chokes. Your choice between ferrite and iron core inductors will depend on factors like frequency range, core loss, and magnetic saturation characteristics.

Material Composition: Ferrite vs. Iron Core

Ferrite cores are composed of ceramic-like iron oxide mixed with metallic elements such as manganese and zinc, offering high electrical resistance and low eddy current losses. Iron cores consist mainly of silicon steel laminations, providing higher magnetic permeability but increased eddy current losses compared to ferrite cores. The material composition of ferrite cores enables superior high-frequency performance, while iron cores excel in low-frequency applications due to their greater magnetic saturation levels.

Electrical Properties Comparison

Ferrite core inductors exhibit higher magnetic permeability and lower core losses at high frequencies compared to iron core inductors, making them ideal for RF applications and switching power supplies. Iron core inductors provide higher inductance values and better saturation tolerance but suffer from greater eddy current losses and lower efficiency at high frequencies. The choice between ferrite and iron cores significantly impacts inductor performance in terms of impedance, Q factor, and thermal stability across different frequency ranges.

Frequency Response Differences

Ferrite core inductors exhibit superior frequency response in high-frequency applications due to their low core losses and high magnetic permeability, enabling efficient operation typically above 100 kHz. In contrast, iron core inductors experience significant eddy current losses at higher frequencies, limiting their effective use to lower frequency ranges, generally below 100 kHz. The intrinsic properties of ferrite materials reduce electromagnetic interference and core heating, enhancing performance in RF circuits and switching power supplies.

Power Handling Capabilities

Ferrite core inductors offer superior power handling capabilities due to their high magnetic permeability and low core losses at high frequencies, making them ideal for switching power supplies and RF applications. Iron core inductors, while able to handle higher currents owing to their saturation characteristics, suffer from higher core losses and reduced efficiency at higher frequencies. Selecting the appropriate core material depends on balancing power ratings, operational frequency, and thermal management requirements for optimal inductor performance.

Core Losses and Efficiency

Ferrite core inductors exhibit lower core losses compared to iron core inductors due to ferrite's higher electrical resistivity and reduced eddy current losses, enhancing overall efficiency in high-frequency applications. Iron core inductors tend to have higher core losses at higher frequencies because of increased hysteresis and eddy currents, reducing efficiency and causing more heat generation. Choosing a ferrite core inductor improves your system's energy efficiency and thermal management, especially in switching power supplies and RF circuits.

Typical Applications for Each Core Type

Ferrite core inductors are typically used in high-frequency applications such as RF circuits, power supplies, and signal filtering due to their low core losses and high magnetic permeability. Iron core inductors excel in low-frequency applications including transformers, audio equipment, and power line chokes, where high inductance and energy storage are required. The choice between ferrite and iron cores depends on frequency range, efficiency, and inductance needs in specific electronic circuits.

Choosing the Right Core: Key Considerations

Choosing the right core for inductors depends on factors like frequency, magnetic permeability, and core losses. Ferrite cores excel at high frequencies due to their low eddy current losses and high resistivity, while iron cores are preferred for low-frequency applications because of their higher saturation flux density and better energy storage capabilities. Understanding your circuit's operating frequency and power requirements will help you select the optimal core to maximize efficiency and performance.

ferrite core vs iron core inductor Infographic

electrown.com

electrown.com