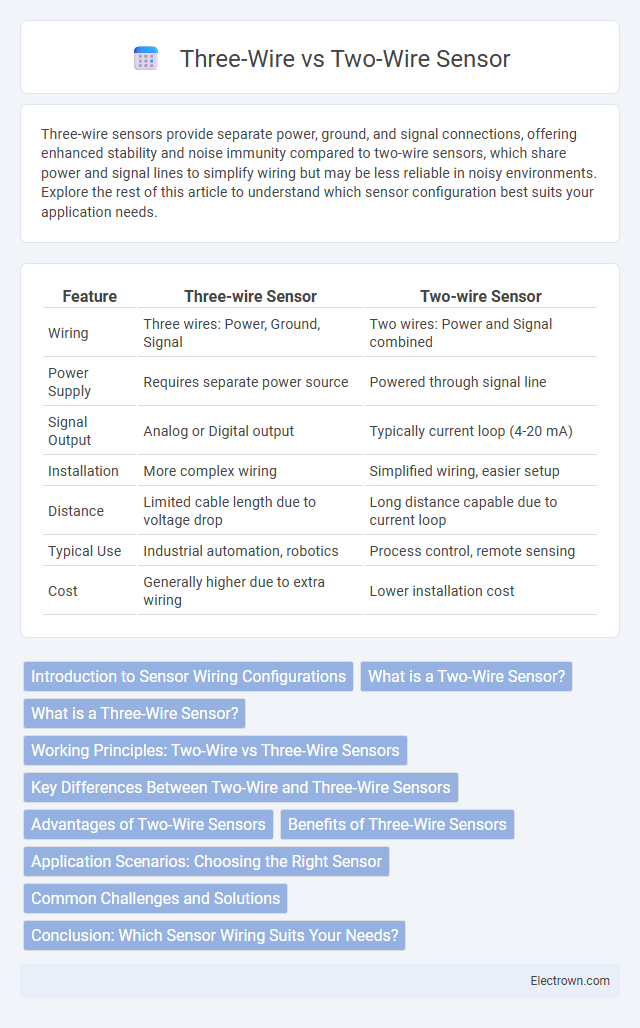

Three-wire sensors provide separate power, ground, and signal connections, offering enhanced stability and noise immunity compared to two-wire sensors, which share power and signal lines to simplify wiring but may be less reliable in noisy environments. Explore the rest of this article to understand which sensor configuration best suits your application needs.

Table of Comparison

| Feature | Three-wire Sensor | Two-wire Sensor |

|---|---|---|

| Wiring | Three wires: Power, Ground, Signal | Two wires: Power and Signal combined |

| Power Supply | Requires separate power source | Powered through signal line |

| Signal Output | Analog or Digital output | Typically current loop (4-20 mA) |

| Installation | More complex wiring | Simplified wiring, easier setup |

| Distance | Limited cable length due to voltage drop | Long distance capable due to current loop |

| Typical Use | Industrial automation, robotics | Process control, remote sensing |

| Cost | Generally higher due to extra wiring | Lower installation cost |

Introduction to Sensor Wiring Configurations

Three-wire sensors typically include a power, ground, and signal wire, enabling separate power supply and signal transmission for accurate readings and improved noise immunity. Two-wire sensors combine power and signal transmission within the same wires, simplifying wiring but often limiting sensor options to those compatible with this configuration. Understanding your sensor wiring configuration is crucial for proper installation, ensuring reliable performance and compatibility with control systems.

What is a Two-Wire Sensor?

A two-wire sensor operates using only two conductors, combining power supply and signal transmission within the same pair of wires, which simplifies wiring and reduces installation costs. Commonly found in industrial automation, these sensors transmit current signals, usually 4-20 mA, that correspond to the measured variable, enabling long-distance communication with minimal signal loss. Their design is ideal for hazardous environments and remote monitoring where power availability and wiring complexity are significant concerns.

What is a Three-Wire Sensor?

A three-wire sensor includes three distinct connections: power supply, ground, and output signal, enabling separate paths for power and signal transmission. This design enhances signal clarity and allows for both analog and digital output options, improving sensor accuracy and reliability in various industrial applications. Your choice of a three-wire sensor ensures better performance and easier integration compared to two-wire sensors that combine power and signal in the same wires.

Working Principles: Two-Wire vs Three-Wire Sensors

Two-wire sensors operate by using the same pair of wires for power supply and signal transmission, typically requiring less wiring complexity but limiting distance and signal strength. Three-wire sensors have separate wires for power, ground, and signal output, allowing for more reliable signal transmission and enhanced noise immunity in industrial environments. Your choice between two-wire and three-wire sensors depends on the application's wiring infrastructure and performance requirements.

Key Differences Between Two-Wire and Three-Wire Sensors

Two-wire sensors integrate power and signal within the same conductors, simplifying wiring but limiting signal strength and distance. Three-wire sensors separate power and signal lines, enhancing accuracy, reducing interference, and enabling longer cable runs. Your choice depends on application requirements for precision, installation complexity, and environmental conditions.

Advantages of Two-Wire Sensors

Two-wire sensors offer simplified installation by requiring only two conductors for both power supply and signal transmission, reducing wiring complexity and cost. Their compatibility with intrinsic safety systems makes them ideal for hazardous environments where minimizing electrical components is critical. Additionally, two-wire sensors consume less power, contributing to longer device lifespan and improved energy efficiency in industrial automation applications.

Benefits of Three-Wire Sensors

Three-wire sensors offer improved accuracy and reliability by providing separate power, ground, and signal lines, reducing signal interference and voltage drops common in two-wire models. Your system benefits from enhanced signal integrity and faster response times due to better electrical isolation. These sensors also support higher output currents, making them suitable for more demanding industrial applications.

Application Scenarios: Choosing the Right Sensor

Three-wire sensors are ideal for applications requiring precise signal transmission and separate power supply, such as industrial automation and robotics, where noise immunity and accurate data are crucial. Two-wire sensors suit simpler, cost-sensitive setups like basic proximity detection and flow measurement, often used in HVAC systems or basic machinery control, benefiting from their simpler wiring and power efficiency. Selecting between these sensors depends on the complexity of the control system, the environmental conditions, and the need for signal integrity and power management.

Common Challenges and Solutions

Three-wire sensors often face challenges such as wiring complexity and electromagnetic interference, impacting signal accuracy and installation time. Two-wire sensors mitigate these issues by simplifying wiring and reducing power consumption but may struggle with limited signal strength and distance. To optimize your sensor system, use shielded cables, proper grounding, and choose the appropriate sensor type based on your application's power and signal requirements.

Conclusion: Which Sensor Wiring Suits Your Needs?

Three-wire sensors offer more stable power supply and faster response times, making them ideal for applications requiring precise and reliable measurements. Two-wire sensors are simpler and cost-effective, suitable for basic detection tasks with lower power consumption. Assess your system's complexity and accuracy needs to choose the sensor wiring that best suits your requirements.

Three-wire vs Two-wire Sensor Infographic

electrown.com

electrown.com