Netlist provides a detailed map of the electrical connections between components in a circuit, while a Bill of Materials (BOM) lists all the physical components needed for assembly. Understanding the differences between these documents is crucial for streamlining your electronic design process; explore the article to learn how each supports your workflow.

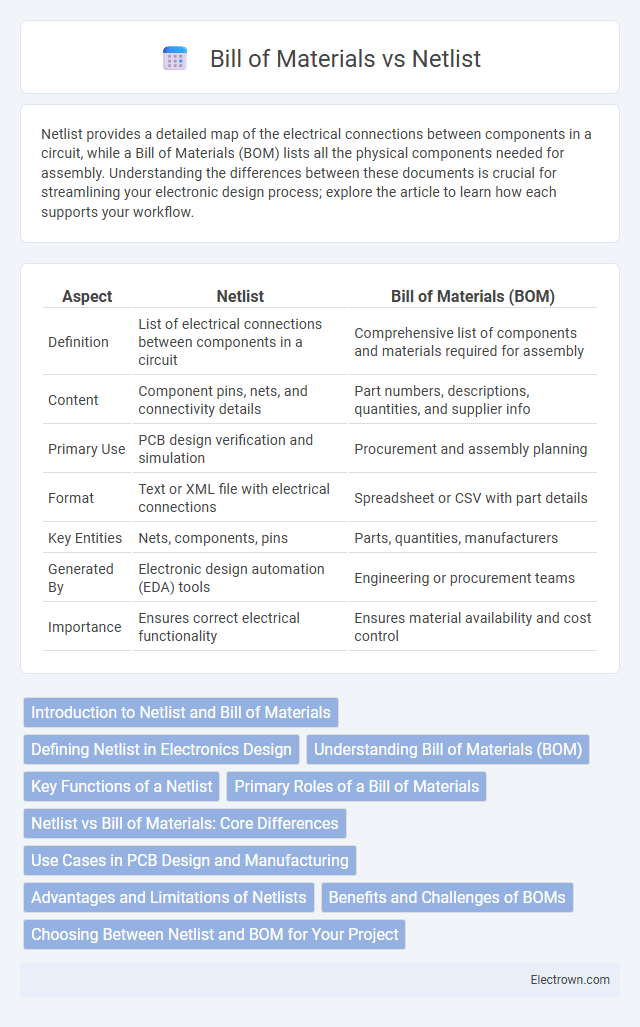

Table of Comparison

| Aspect | Netlist | Bill of Materials (BOM) |

|---|---|---|

| Definition | List of electrical connections between components in a circuit | Comprehensive list of components and materials required for assembly |

| Content | Component pins, nets, and connectivity details | Part numbers, descriptions, quantities, and supplier info |

| Primary Use | PCB design verification and simulation | Procurement and assembly planning |

| Format | Text or XML file with electrical connections | Spreadsheet or CSV with part details |

| Key Entities | Nets, components, pins | Parts, quantities, manufacturers |

| Generated By | Electronic design automation (EDA) tools | Engineering or procurement teams |

| Importance | Ensures correct electrical functionality | Ensures material availability and cost control |

Introduction to Netlist and Bill of Materials

A Netlist is a detailed electrical schematic that defines the connectivity between electronic components in a circuit design, essential for PCB layout and simulation. The Bill of Materials (BOM) lists all components, parts, and materials required to manufacture the electronic assembly, including quantities, part numbers, and specifications. Understanding the distinction between a Netlist and a BOM helps you efficiently manage design and production workflows in electronics manufacturing.

Defining Netlist in Electronics Design

A netlist in electronics design is a detailed electronic blueprint that lists all the components and their interconnections within a circuit, serving as a critical step before PCB layout. Unlike a Bill of Materials (BOM), which primarily catalogs parts and quantities, the netlist maps the electrical connectivity between components to ensure proper circuit functionality. Understanding your netlist is essential for accurate design verification and seamless transition from schematic to manufacturing.

Understanding Bill of Materials (BOM)

A Bill of Materials (BOM) is a comprehensive list detailing all components, parts, and raw materials required to manufacture a product, including quantities and specifications. Unlike a netlist, which shows electrical connections between components in a circuit design, the BOM focuses on the physical inventory and sourcing needed during production. You can use a BOM to streamline procurement, inventory management, and assembly processes effectively.

Key Functions of a Netlist

A netlist is a critical document in electronic design that details the connectivity between components, specifying nodes and electrical connections essential for circuit functionality. It acts as the blueprint for PCB layout and simulation, enabling verification of design integrity and identification of potential errors before manufacturing. Your design process relies on the netlist to accurately translate schematic diagrams into physical layouts, ensuring seamless communication between design and production stages.

Primary Roles of a Bill of Materials

A Bill of Materials (BOM) serves as the authoritative list detailing all components, quantities, and specifications required to manufacture a product, ensuring accurate procurement and assembly processes. It enables effective inventory management by providing precise part identification, supporting cost estimation and production scheduling. Unlike a netlist, which defines the electrical connections and circuit topology, the BOM focuses on the physical makeup and logistics of the product build.

Netlist vs Bill of Materials: Core Differences

The core differences between a netlist and a bill of materials (BOM) lie in their functions: a netlist details the electronic components' interconnections within a circuit design, specifying how each component's pins are linked, while a BOM lists all components required for manufacturing, including quantities, part numbers, and descriptions. Netlists are primarily used for circuit simulation and PCB layout verification, whereas BOMs serve procurement and assembly processes by providing a comprehensive inventory of parts. Understanding these distinctions is crucial for efficient electronic design automation (EDA) workflows and ensuring accurate production documentation.

Use Cases in PCB Design and Manufacturing

A netlist in PCB design provides a detailed map of electrical connections between components, essential for circuit verification and layout integrity. The Bill of Materials (BOM) lists all components with specifications, quantities, and sourcing details critical for procurement and assembly planning. Together, the netlist ensures correct wiring while the BOM facilitates inventory management and cost estimation in manufacturing.

Advantages and Limitations of Netlists

Netlists provide a detailed representation of electronic components and their interconnections, enabling precise circuit analysis and simulation. They streamline the design verification process by highlighting connectivity errors early, reducing costly physical prototyping. However, netlists often lack comprehensive component specifications like quantities and sourcing details, limiting their use in procurement and assembly compared to a full Bill of Materials.

Benefits and Challenges of BOMs

Bill of Materials (BOMs) offer detailed component lists essential for product manufacturing, enabling precise cost estimation and streamlined procurement processes. They facilitate clear communication between design and production teams, reducing errors and improving project timelines. However, BOMs can be complex to manage due to frequent updates and version control challenges, requiring robust software tools to ensure accuracy and consistency.

Choosing Between Netlist and BOM for Your Project

Choosing between a Netlist and a Bill of Materials (BOM) depends on the project's phase and focus; the Netlist details electrical connectivity and logical connections essential for circuit design validation, while the BOM lists all physical components required for assembly and procurement. Engineers prioritize the Netlist during schematic capture and PCB layout for defining component interrelations, whereas manufacturers rely heavily on the BOM for sourcing and inventory management. Effective project execution requires integrating both documents to ensure accurate design implementation and streamlined production workflows.

Netlist vs Bill of Materials Infographic

electrown.com

electrown.com