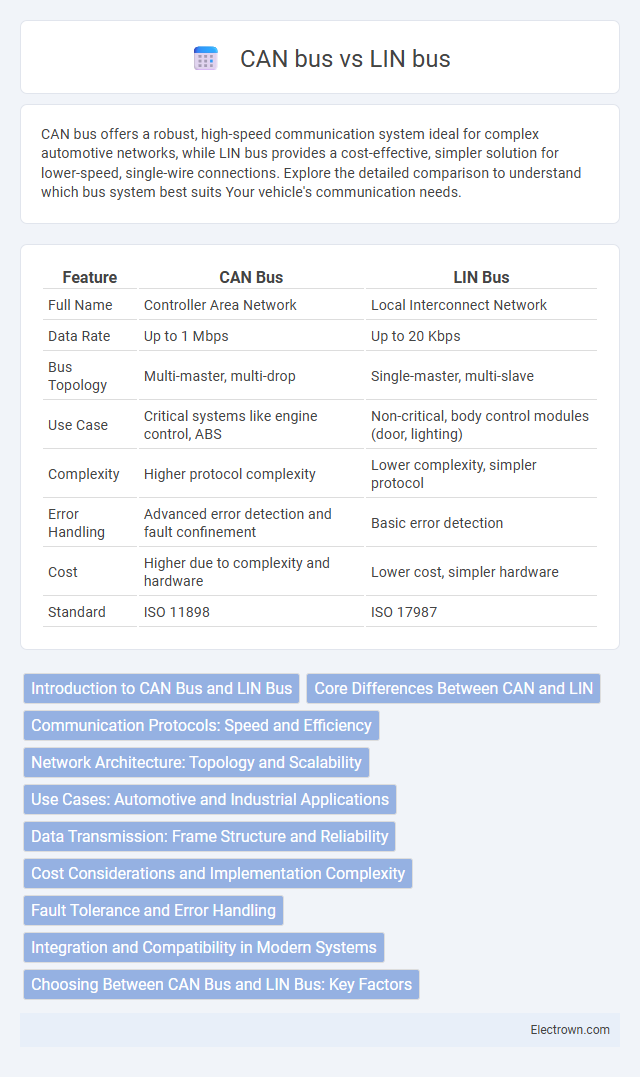

CAN bus offers a robust, high-speed communication system ideal for complex automotive networks, while LIN bus provides a cost-effective, simpler solution for lower-speed, single-wire connections. Explore the detailed comparison to understand which bus system best suits Your vehicle's communication needs.

Table of Comparison

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Full Name | Controller Area Network | Local Interconnect Network |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Bus Topology | Multi-master, multi-drop | Single-master, multi-slave |

| Use Case | Critical systems like engine control, ABS | Non-critical, body control modules (door, lighting) |

| Complexity | Higher protocol complexity | Lower complexity, simpler protocol |

| Error Handling | Advanced error detection and fault confinement | Basic error detection |

| Cost | Higher due to complexity and hardware | Lower cost, simpler hardware |

| Standard | ISO 11898 | ISO 17987 |

Introduction to CAN Bus and LIN Bus

CAN Bus (Controller Area Network) is a robust vehicle bus standard designed to allow microcontrollers and devices to communicate without a host computer, commonly used in automotive and industrial applications for high-speed data transfer. LIN Bus (Local Interconnect Network) is a lower-cost, slower network protocol that complements CAN by managing simpler, low-speed sensor and actuator communication in vehicles. Both protocols optimize in-vehicle networking but differ significantly in speed, complexity, and application scope.

Core Differences Between CAN and LIN

CAN bus offers higher data transfer rates up to 1 Mbps and supports complex multi-master communication, making it ideal for critical automotive systems requiring robust error handling. LIN bus operates at lower speeds, typically up to 20 Kbps, designed for simpler, cost-effective communication in body electronics with a single-master, multiple-slave arrangement. Your choice between CAN and LIN depends on the need for speed, network complexity, and cost-efficiency in vehicle communication systems.

Communication Protocols: Speed and Efficiency

CAN bus offers high-speed communication up to 1 Mbps with robust error handling and real-time data transmission, making it ideal for complex automotive and industrial applications. LIN bus provides a simpler, lower-speed protocol typically operating at 20 Kbps, optimizing cost and efficiency for less critical communication tasks like sensor and actuator management. Both protocols complement each other, with CAN bus ensuring faster, more reliable data exchange while LIN bus reduces complexity and power consumption in vehicle networks.

Network Architecture: Topology and Scalability

CAN bus features a robust multi-master bus topology allowing multiple nodes to communicate efficiently with high scalability in complex automotive networks. LIN bus employs a single-master, multiple-slave linear topology optimized for low-cost, low-speed communication with limited scalability in network size. CAN's flexible arbitration and error handling support larger, more intricate networks, whereas LIN's simpler structure suits less critical, localized control applications.

Use Cases: Automotive and Industrial Applications

CAN bus excels in automotive and industrial applications requiring high-speed, robust communication for complex control systems, such as engine management, ABS, and factory automation. LIN bus suits cost-sensitive automotive tasks with lower bandwidth needs, including body electronics like window controls and seat adjustments. Industrial environments favor CAN for real-time data exchange and LIN for simpler, localized device networks.

Data Transmission: Frame Structure and Reliability

CAN bus features a robust frame structure with standard and extended formats, offering high data integrity through error detection mechanisms like CRC and acknowledgement bits, ensuring reliable transmission in automotive networks. LIN bus uses a simpler frame structure with a break field, sync, identifier, and data, designed for lower-speed communication, prioritizing cost-effectiveness over fault tolerance. Your choice between CAN and LIN depends on the required data transmission speed, complexity, and reliability for your vehicle's network architecture.

Cost Considerations and Implementation Complexity

CAN bus systems generally incur higher costs due to more complex hardware requirements and advanced error handling capabilities, making them suitable for applications demanding robust communication. LIN bus offers a cost-effective alternative with simpler implementation and reduced wiring complexity, ideal for basic control functions in automotive and industrial environments. Evaluating Your project's performance needs and budget constraints helps determine the optimal choice between CAN and LIN bus architectures.

Fault Tolerance and Error Handling

CAN bus offers superior fault tolerance and error handling through built-in error detection mechanisms such as bit monitoring, CRC checks, and automatic retransmission, ensuring reliable communication in complex networks. LIN bus, designed for cost-effective, low-speed applications, has limited fault tolerance and simpler error handling, typically relying on checksum validation and master-slave synchronization. Your choice between CAN and LIN buses should consider the criticality of fault management in your automotive or industrial system.

Integration and Compatibility in Modern Systems

CAN bus offers robust integration capabilities and is widely compatible with various automotive and industrial systems due to its high-speed data transfer and multi-master communication. LIN bus complements CAN by providing a cost-effective solution for simpler, low-speed networks, often used for peripheral device control within modern vehicles. Your choice between CAN and LIN buses depends on system complexity, required data rates, and the level of network integration needed.

Choosing Between CAN Bus and LIN Bus: Key Factors

Choosing between CAN bus and LIN bus depends on factors such as data transmission speed, network complexity, and application requirements. CAN bus supports higher speeds up to 1 Mbps and is ideal for real-time, critical communication in automotive systems, while LIN bus operates at lower speeds (up to 20 Kbps) suited for simpler, cost-sensitive applications like window or seat controls. The decision hinges on balancing performance needs, cost constraints, and system scalability in automotive or industrial environments.

CAN bus vs LIN bus Infographic

electrown.com

electrown.com