High-k dielectrics offer superior capacitance and reduced leakage current compared to low-k dielectrics, making them essential for scaling down transistors in nanoelectronics. Discover how your device performance and energy efficiency can be optimized by understanding the key differences and applications of these materials.

Table of Comparison

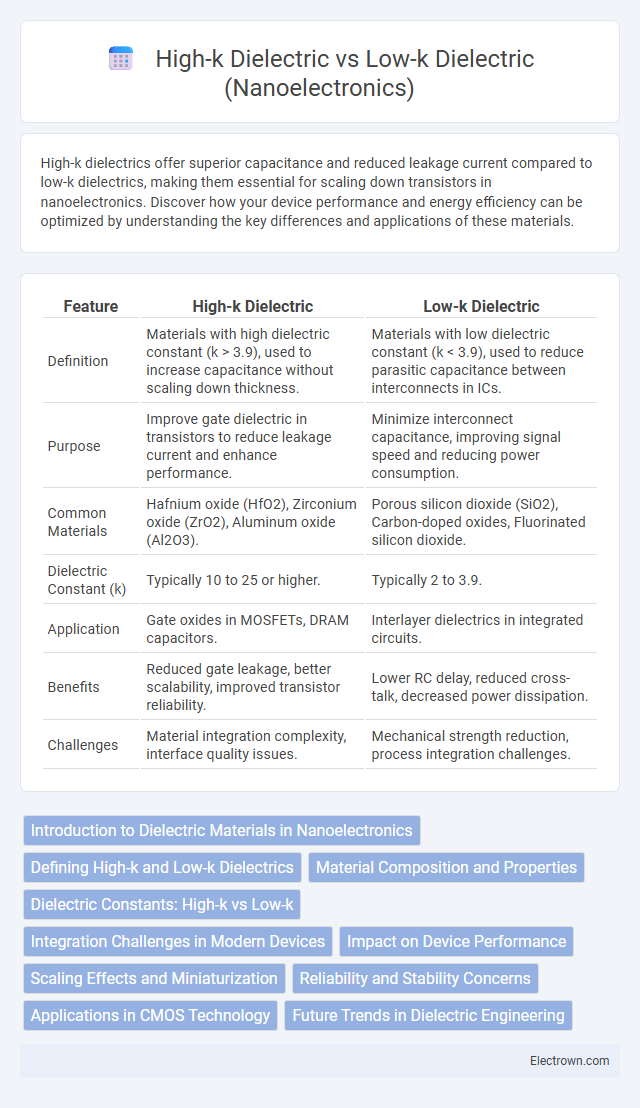

| Feature | High-k Dielectric | Low-k Dielectric |

|---|---|---|

| Definition | Materials with high dielectric constant (k > 3.9), used to increase capacitance without scaling down thickness. | Materials with low dielectric constant (k < 3.9), used to reduce parasitic capacitance between interconnects in ICs. |

| Purpose | Improve gate dielectric in transistors to reduce leakage current and enhance performance. | Minimize interconnect capacitance, improving signal speed and reducing power consumption. |

| Common Materials | Hafnium oxide (HfO2), Zirconium oxide (ZrO2), Aluminum oxide (Al2O3). | Porous silicon dioxide (SiO2), Carbon-doped oxides, Fluorinated silicon dioxide. |

| Dielectric Constant (k) | Typically 10 to 25 or higher. | Typically 2 to 3.9. |

| Application | Gate oxides in MOSFETs, DRAM capacitors. | Interlayer dielectrics in integrated circuits. |

| Benefits | Reduced gate leakage, better scalability, improved transistor reliability. | Lower RC delay, reduced cross-talk, decreased power dissipation. |

| Challenges | Material integration complexity, interface quality issues. | Mechanical strength reduction, process integration challenges. |

Introduction to Dielectric Materials in Nanoelectronics

Dielectric materials in nanoelectronics serve as insulators that control electric fields and reduce power consumption in integrated circuits. High-k dielectrics, such as hafnium oxide (HfO2), offer increased capacitance by allowing thicker layers without leakage, enhancing transistor performance at nanoscale dimensions. Low-k dielectrics, typically porous silicon dioxide or organic polymers, minimize parasitic capacitance between interconnects, improving signal speed and reducing crosstalk in densely packed circuits.

Defining High-k and Low-k Dielectrics

High-k dielectrics refer to materials with a high dielectric constant, typically greater than 10, used to increase capacitance without scaling down physical thickness in nanoelectronic devices. Low-k dielectrics have a dielectric constant lower than 4, aiming to reduce parasitic capacitance and improve signal speed between interconnects in integrated circuits. Your choice between high-k and low-k dielectrics directly impacts device performance, power consumption, and scaling potential in semiconductor manufacturing.

Material Composition and Properties

High-k dielectrics typically consist of materials like hafnium oxide (HfO2) or zirconium oxide (ZrO2), offering a high dielectric constant that enhances gate capacitance and reduces leakage current in nanoelectronics. Low-k dielectrics, often made from porous silica or organic polymers, provide a lower dielectric constant that minimizes parasitic capacitance and improves signal speed in interconnects. Your choice between high-k and low-k dielectrics depends on balancing insulation properties with device performance and scaling requirements.

Dielectric Constants: High-k vs Low-k

High-k dielectrics possess dielectric constants typically ranging from 10 to over 25, significantly higher than low-k dielectrics, which usually have dielectric constants below 3.9, such as silicon dioxide with a k-value of about 3.9 and various porous or organic materials exhibiting k-values as low as 2. Low-k dielectrics reduce parasitic capacitance in nanoelectronic devices, enhancing speed and lowering power consumption, whereas high-k dielectrics improve gate control and reduce leakage currents in advanced transistor designs.

Integration Challenges in Modern Devices

High-k dielectrics face integration challenges such as interface instability, increased trap densities, and compatibility issues with existing silicon processes, which can degrade device performance and reliability. Low-k dielectrics, while reducing parasitic capacitance for faster signal transmission, struggle with mechanical fragility and susceptibility to moisture absorption, leading to integration complexity in ultra-scaled interconnects. Your choice between high-k and low-k materials must balance electrical performance with manufacturability to overcome these challenges in advanced nanoelectronic devices.

Impact on Device Performance

High-k dielectrics enhance device performance by reducing gate leakage current and enabling further device scaling, leading to improved power efficiency and higher transistor speed. Low-k dielectrics minimize parasitic capacitance in interconnects, reducing RC delay and enhancing signal integrity, critical for high-frequency nanoelectronic circuits. Balancing high-k gate insulators with low-k interlayer dielectrics optimizes overall device performance by addressing both transistor switching speed and interconnect signal delay.

Scaling Effects and Miniaturization

High-k dielectrics enable further scaling in nanoelectronics by providing higher capacitance without increasing leakage currents, essential for minimizing transistor gate thickness at the nanoscale. Low-k dielectrics reduce parasitic capacitance between interconnects, improving signal speed and reducing power consumption in tightly packed circuits. Your choice between high-k and low-k materials directly influences device performance, scaling limits, and overall miniaturization efficiency.

Reliability and Stability Concerns

High-k dielectrics such as hafnium oxide offer improved gate capacitance and reduced leakage currents but face reliability challenges like bias temperature instability (BTI) and charge trapping, which can degrade transistor performance over time. Low-k dielectrics, commonly used in interconnects to minimize parasitic capacitance, suffer from mechanical fragility and higher susceptibility to dielectric breakdown, impacting long-term stability. Advanced material engineering and process optimization are essential to enhance the reliability and stability of both high-k and low-k dielectrics in nanoelectronic applications.

Applications in CMOS Technology

High-k dielectrics such as hafnium oxide (HfO2) are crucial in CMOS technology for gate insulators, enabling further transistor scaling by reducing gate leakage current and improving capacitance without increasing physical thickness. Low-k dielectrics, often silicon-based or organic materials with dielectric constants below 3.0, are primarily used as interlayer dielectrics to minimize parasitic capacitance and enhance signal speed in metal interconnects of CMOS devices. The integration of high-k/metal gate stacks and low-k dielectrics collectively boosts device performance and energy efficiency in advanced nanoscale CMOS architectures.

Future Trends in Dielectric Engineering

High-k dielectrics continue to revolutionize nanoelectronics by enabling further miniaturization and enhanced gate control in transistors, while low-k dielectrics improve signal speed and reduce capacitive coupling in interconnects. Future trends in dielectric engineering emphasize developing novel materials with superior dielectric constants and thermal stability to balance scaling challenges and power efficiency. Your ability to integrate emerging dielectrics will determine the performance and reliability of next-generation semiconductor devices.

High-k dielectric vs Low-k dielectric (nanoelectronics) Infographic

electrown.com

electrown.com