Nano-optomechanical devices leverage light to control mechanical motion at the nanoscale, offering high sensitivity and ultra-fast response times ideal for precision sensing and signal processing. Understanding the key differences and applications of nano-optomechanical versus nanoelectromechanical devices can enhance your grasp of emerging nanotechnologies--explore the rest of the article to discover how these innovations impact future tech.

Table of Comparison

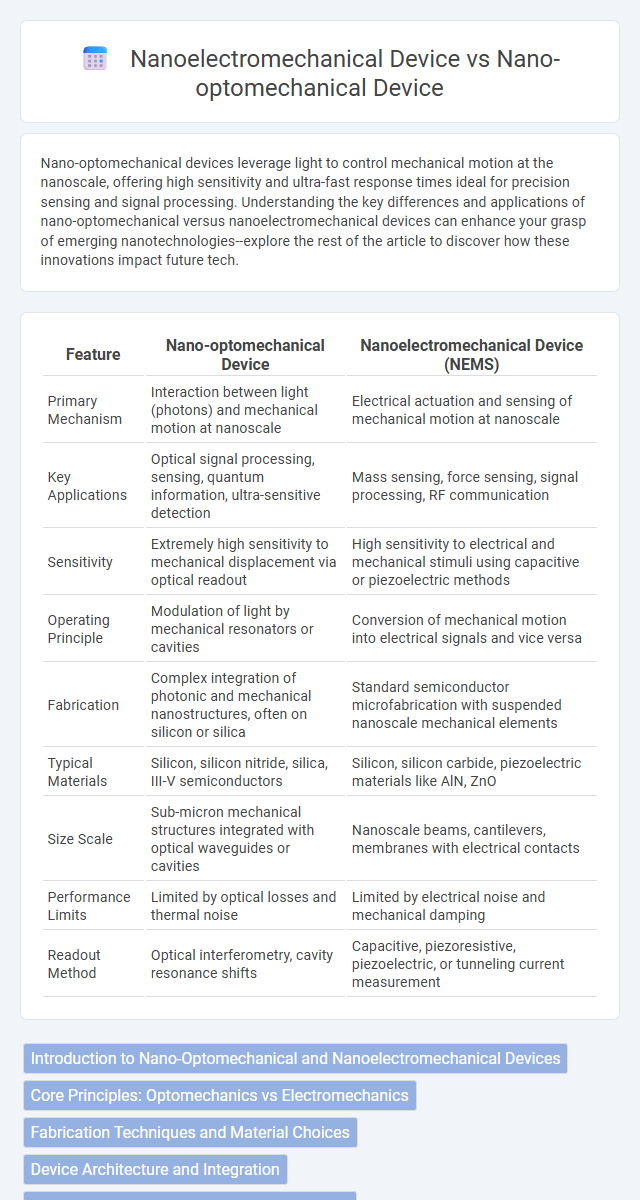

| Feature | Nano-optomechanical Device | Nanoelectromechanical Device (NEMS) |

|---|---|---|

| Primary Mechanism | Interaction between light (photons) and mechanical motion at nanoscale | Electrical actuation and sensing of mechanical motion at nanoscale |

| Key Applications | Optical signal processing, sensing, quantum information, ultra-sensitive detection | Mass sensing, force sensing, signal processing, RF communication |

| Sensitivity | Extremely high sensitivity to mechanical displacement via optical readout | High sensitivity to electrical and mechanical stimuli using capacitive or piezoelectric methods |

| Operating Principle | Modulation of light by mechanical resonators or cavities | Conversion of mechanical motion into electrical signals and vice versa |

| Fabrication | Complex integration of photonic and mechanical nanostructures, often on silicon or silica | Standard semiconductor microfabrication with suspended nanoscale mechanical elements |

| Typical Materials | Silicon, silicon nitride, silica, III-V semiconductors | Silicon, silicon carbide, piezoelectric materials like AlN, ZnO |

| Size Scale | Sub-micron mechanical structures integrated with optical waveguides or cavities | Nanoscale beams, cantilevers, membranes with electrical contacts |

| Performance Limits | Limited by optical losses and thermal noise | Limited by electrical noise and mechanical damping |

| Readout Method | Optical interferometry, cavity resonance shifts | Capacitive, piezoresistive, piezoelectric, or tunneling current measurement |

Introduction to Nano-Optomechanical and Nanoelectromechanical Devices

Nano-optomechanical devices exploit the interaction between light and mechanical motion at the nanoscale, enabling high-precision sensing and signal processing through optical forces. Nanoelectromechanical devices integrate electrical and mechanical functionalities on a nanoscale, using electrical signals to actuate or sense mechanical motion for applications in energy harvesting and communication systems. Your choice between these technologies depends on the specific requirements for sensitivity, speed, and integration in advanced nanoscale systems.

Core Principles: Optomechanics vs Electromechanics

Nano-optomechanical devices rely on the interaction between light (photons) and mechanical motion at the nanoscale, utilizing radiation pressure or electromagnetic fields to control mechanical vibrations. In contrast, nanoelectromechanical devices operate based on electrostatic forces or electrical signals to actuate and sense nanoscale mechanical movements. Your choice between these technologies depends on application-specific needs such as precision in optical control or electrical integration.

Fabrication Techniques and Material Choices

Nano-optomechanical devices commonly utilize fabrication techniques such as electron beam lithography and reactive ion etching to create high-precision photonic structures, primarily employing materials like silicon, silicon nitride, and gallium arsenide due to their excellent optical properties. In contrast, nanoelectromechanical systems (NEMS) often rely on top-down fabrication methods including photolithography and surface micromachining, utilizing materials such as silicon, silicon carbide, and metals like gold or aluminum for their superior mechanical and electrical conductivity. Material selection in nano-optomechanical devices prioritizes optical transparency and low optical losses, whereas in NEMS, mechanical robustness and electrical performance are critical factors guiding material choice.

Device Architecture and Integration

Nano-optomechanical devices leverage optomechanical cavities integrating photonic components with mechanical resonators, enabling ultra-sensitive signal transduction through light-matter interaction. Nanoelectromechanical devices combine nanoscale mechanical elements with electrical circuits, featuring capacitive or piezoelectric coupling for signal readout and actuation. Both architectures emphasize seamless integration with semiconductor platforms, but nano-optomechanical devices prioritize optical waveguide networks, whereas nanoelectromechanical devices focus on electrical interconnects and CMOS compatibility.

Sensing Capabilities and Signal Transduction

Nano-optomechanical devices leverage optical fields to detect mechanical motion at the nanoscale with exceptional sensitivity, enabling ultra-precise displacement, force, and mass sensing through changes in light intensity, phase, or frequency. Nanoelectromechanical devices convert mechanical signals into electrical signals using capacitive, piezoresistive, or piezoelectric transduction mechanisms, offering high sensitivity for pressure, acceleration, and biomolecular detection with direct electrical readout. Optical detection in nano-optomechanical systems typically achieves lower noise floors and higher bandwidths compared to the electrically-based signal transduction in nanoelectromechanical systems, enhancing performance in applications requiring real-time and high-resolution sensing.

Energy Efficiency and Power Consumption

Nano-optomechanical devices leverage light-matter interactions to achieve ultra-low power consumption through minimal thermal losses and high sensitivity in signal transduction, outperforming nanoelectromechanical devices that typically rely on electrical actuation and exhibit higher Joule heating effects. The energy efficiency of nano-optomechanical systems is enhanced by their ability to operate at optical frequencies with reduced electrical interference, while nanoelectromechanical devices consume more power during mechanical motion due to resistive and capacitive losses inherent in electrical circuits. As a result, nano-optomechanical devices are more suitable for applications demanding low energy footprints and sustained operation with minimized power dissipation.

Communication Speed and Bandwidth Performance

Nano-optomechanical devices offer superior communication speed and bandwidth performance compared to nanoelectromechanical devices due to their utilization of light signals, which inherently provide higher frequencies and lower signal loss. These devices enable data transmission at terahertz frequencies, significantly surpassing the gigahertz range typical of nanoelectromechanical systems. Your applications can benefit from enhanced signal integrity and faster processing speeds when leveraging nano-optomechanical technology for high-bandwidth communication demands.

Application Domains: Biomedical, Quantum, and Telecom

Nano-optomechanical devices excel in biomedical applications by enabling ultra-sensitive detection of biomolecules through light-matter interactions, offering advancements in diagnostics and single-cell analysis. In quantum technology, these devices facilitate coherent control and readout of quantum states, enhancing quantum computing and communication systems with high fidelity. Telecom industries benefit from nano-optomechanical resonators by improving signal processing and enabling tunable photonic components for high-speed, low-loss optical networks.

Recent Advances and Breakthrough Innovations

Recent advances in nano-optomechanical devices include enhanced light-matter interaction at the nanoscale, enabling ultra-sensitive detection and improved signal modulation in integrated photonic circuits. Breakthrough innovations feature the development of hybrid systems combining mechanical resonators with optical cavities for applications in quantum computing and precision metrology. Conversely, nanoelectromechanical devices have seen significant progress in energy-efficient actuation, miniaturized sensors, and resonators with high Q-factors, driving advancements in communication technology and biomedical diagnostics.

Future Prospects and Research Challenges

Nano-optomechanical devices exhibit promising future prospects in ultra-sensitive sensors and quantum information processing due to their ability to couple light with mechanical motion at the nanoscale. Research challenges for nano-optomechanical devices include improving fabrication precision and minimizing thermal noise to enhance signal fidelity. Your advancements in nanoelectromechanical devices focus on integrating electrical control with mechanical resonators, but challenges remain in scaling down device size while maintaining performance and reliability.

Nano-optomechanical Device vs Nanoelectromechanical Device Infographic

electrown.com

electrown.com