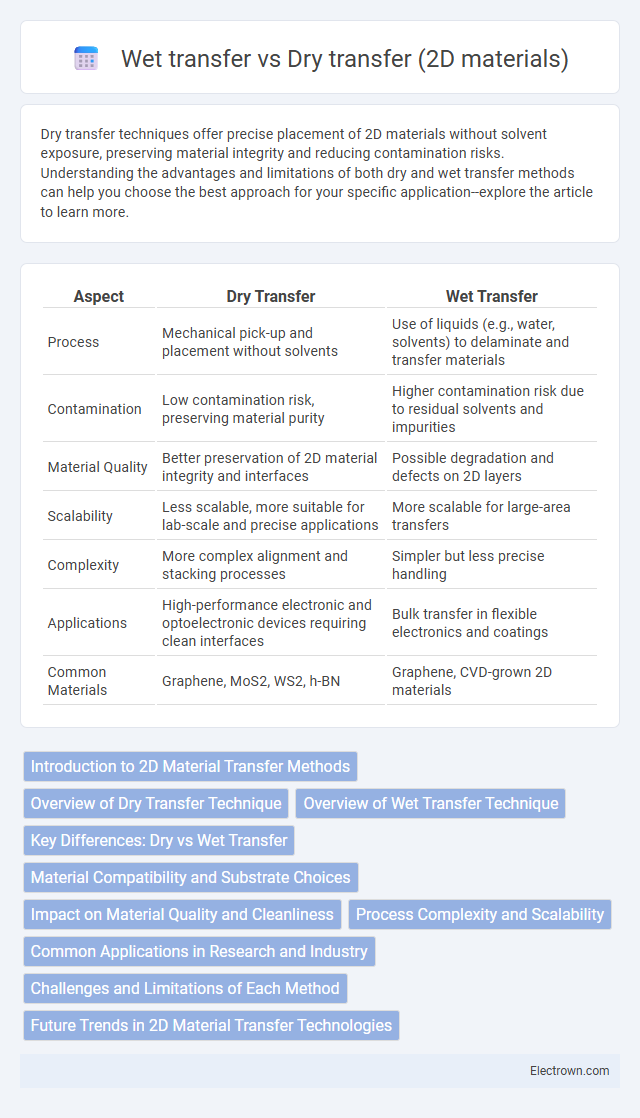

Dry transfer techniques offer precise placement of 2D materials without solvent exposure, preserving material integrity and reducing contamination risks. Understanding the advantages and limitations of both dry and wet transfer methods can help you choose the best approach for your specific application--explore the article to learn more.

Table of Comparison

| Aspect | Dry Transfer | Wet Transfer |

|---|---|---|

| Process | Mechanical pick-up and placement without solvents | Use of liquids (e.g., water, solvents) to delaminate and transfer materials |

| Contamination | Low contamination risk, preserving material purity | Higher contamination risk due to residual solvents and impurities |

| Material Quality | Better preservation of 2D material integrity and interfaces | Possible degradation and defects on 2D layers |

| Scalability | Less scalable, more suitable for lab-scale and precise applications | More scalable for large-area transfers |

| Complexity | More complex alignment and stacking processes | Simpler but less precise handling |

| Applications | High-performance electronic and optoelectronic devices requiring clean interfaces | Bulk transfer in flexible electronics and coatings |

| Common Materials | Graphene, MoS2, WS2, h-BN | Graphene, CVD-grown 2D materials |

Introduction to 2D Material Transfer Methods

Dry transfer of 2D materials involves mechanically picking up and placing layers without the use of solvents, preserving material quality and minimizing contamination. Wet transfer methods utilize liquid mediums to detach and transfer 2D layers, often leading to potential residue and degradation in electronic properties. Choosing between dry and wet transfer depends on factors like desired interface cleanliness, device performance requirements, and scalability for applications in nanoelectronics and optoelectronics.

Overview of Dry Transfer Technique

The dry transfer technique for 2D materials involves the precise mechanical picking and placing of atomically thin layers using polymer stamps without liquid solvents, preserving material integrity and interface quality. This method reduces contamination and strain, enabling high-resolution stacking crucial for heterostructure assembly in van der Waals devices. It is widely used to fabricate clean interfaces with controlled twist angles, enhancing the electronic and optical properties of materials like graphene and transition metal dichalcogenides.

Overview of Wet Transfer Technique

The wet transfer technique for 2D materials involves using a liquid medium, typically water or solvents, to facilitate the transfer of thin layers from a growth substrate to a target substrate, ensuring the material remains intact and preserves its structural properties. This method often employs polymer supports such as PMMA to stabilize the 2D material during the etching of the original substrate, allowing precise positioning on the desired surface. Your ability to achieve high-quality, defect-minimized 2D material transfer depends on controlling parameters like etching time, cleanliness of the liquid, and removal of polymer residues.

Key Differences: Dry vs Wet Transfer

Dry transfer of 2D materials involves the mechanical stacking of flakes without solvents, preserving cleaner interfaces and minimizing contamination. Wet transfer uses chemical solvents to dissolve the substrate or support layer, which can introduce residues and cause wrinkles or bubbles. Your choice depends on the required interface quality and device performance, as dry transfer offers higher precision while wet transfer is simpler and scalable.

Material Compatibility and Substrate Choices

Dry transfer techniques for 2D materials offer greater compatibility with sensitive substrates such as flexible polymers and temperature-sensitive dielectrics by avoiding solvents and high-temperature processes. Wet transfer methods enable effective transfer to rigid substrates like silicon dioxide and sapphire but often introduce solvent residues that can degrade material quality and interfacial properties. Choice of substrate and material compatibility is critical in optimizing the performance of heterostructures, with dry transfer preferred for preserving pristine interfaces and wet transfer favored for scalable integration on robust substrates.

Impact on Material Quality and Cleanliness

Dry transfer methods for 2D materials significantly reduce contamination and preserve the intrinsic material quality by avoiding solvents that can introduce residues. Wet transfer techniques often involve chemicals that risk degrading the surface cleanliness and induce defects, impacting electronic properties. Maintaining a contamination-free interface is critical for high-performance device applications, making dry transfer preferable for pristine heterostructures.

Process Complexity and Scalability

Dry transfer methods for 2D materials offer lower process complexity by eliminating solvents, enabling cleaner interfaces and precise layer alignment, but often face challenges in scalability due to manual handling and equipment limitations. Wet transfer techniques involve chemical etching and solvent baths, increasing process complexity and risk of contamination, yet they are more scalable for large-area substrates used in industrial applications. Your choice depends on balancing cleanliness and precision against throughput requirements in device fabrication.

Common Applications in Research and Industry

Dry transfer techniques are widely used in research for assembling high-quality 2D material heterostructures with precise layer alignment, crucial for electronic and photonic device fabrication. Wet transfer methods are common in industrial-scale processes involving graphene and other 2D materials for flexible electronics and large-area coatings, where scalability and cost-effectiveness are prioritized. Your choice between dry and wet transfer impacts device performance and manufacturing efficiency depending on the specific application requirements.

Challenges and Limitations of Each Method

Dry transfer of 2D materials often faces challenges such as limited adhesion control and mechanical strain, which can cause cracks or wrinkles, reducing device performance. Wet transfer methods, while providing better surface conformity and scalability, suffer from contamination due to residual solvents and difficulty in achieving precise layer alignment. Your choice between these techniques depends on balancing the need for cleanliness versus layer integrity and scalability in 2D material fabrication.

Future Trends in 2D Material Transfer Technologies

Future trends in 2D material transfer technologies emphasize scalable, contamination-free methods to enhance device performance and integration. Dry transfer techniques are evolving with improved precision and automation, reducing mechanical strain and enabling reproducible stacking of heterostructures. Wet transfer methods are being optimized to minimize residue and enhance interface quality, supporting large-area fabrication essential for industrial applications.

Dry transfer vs Wet transfer (2D materials) Infographic

electrown.com

electrown.com