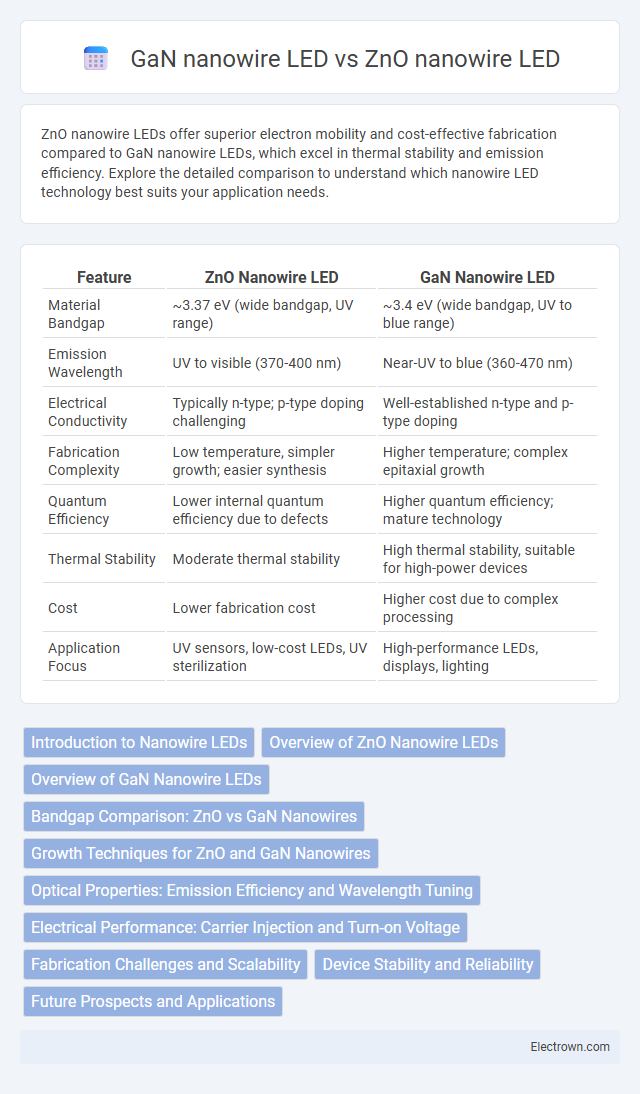

ZnO nanowire LEDs offer superior electron mobility and cost-effective fabrication compared to GaN nanowire LEDs, which excel in thermal stability and emission efficiency. Explore the detailed comparison to understand which nanowire LED technology best suits your application needs.

Table of Comparison

| Feature | ZnO Nanowire LED | GaN Nanowire LED |

|---|---|---|

| Material Bandgap | ~3.37 eV (wide bandgap, UV range) | ~3.4 eV (wide bandgap, UV to blue range) |

| Emission Wavelength | UV to visible (370-400 nm) | Near-UV to blue (360-470 nm) |

| Electrical Conductivity | Typically n-type; p-type doping challenging | Well-established n-type and p-type doping |

| Fabrication Complexity | Low temperature, simpler growth; easier synthesis | Higher temperature; complex epitaxial growth |

| Quantum Efficiency | Lower internal quantum efficiency due to defects | Higher quantum efficiency; mature technology |

| Thermal Stability | Moderate thermal stability | High thermal stability, suitable for high-power devices |

| Cost | Lower fabrication cost | Higher cost due to complex processing |

| Application Focus | UV sensors, low-cost LEDs, UV sterilization | High-performance LEDs, displays, lighting |

Introduction to Nanowire LEDs

Nanowire LEDs utilize semiconductor nanowires to enhance light emission efficiency and color purity. ZnO nanowire LEDs offer advantages such as wide bandgap properties and high exciton binding energy, making them suitable for ultraviolet and blue light applications. GaN nanowire LEDs provide superior thermal stability and robustness, ideal for high-power, high-brightness displays, with your choice depending on the desired wavelength and device performance.

Overview of ZnO Nanowire LEDs

ZnO nanowire LEDs exhibit excellent optical properties due to their wide direct bandgap of approximately 3.37 eV and high exciton binding energy of 60 meV, enabling efficient ultraviolet to visible emission at room temperature. Their synthesis via low-temperature hydrothermal methods offers a cost-effective and scalable alternative compared to GaN nanowire LEDs, which typically require high-temperature metal-organic chemical vapor deposition (MOCVD). ZnO nanowire LEDs demonstrate potential advantages in transparency, mechanical flexibility, and environmental stability, making them promising candidates for next-generation optoelectronic devices.

Overview of GaN Nanowire LEDs

GaN nanowire LEDs exhibit superior performance due to their direct wide bandgap of approximately 3.4 eV, enabling efficient ultraviolet to visible light emission and high electron mobility. Their nanowire structure reduces defect densities and strain compared to planar LEDs, resulting in enhanced luminous efficiency and longer device lifespan. You benefit from GaN nanowire LEDs' greater thermal stability and compatibility with existing semiconductor technologies, making them ideal for high-power and high-frequency optoelectronic applications.

Bandgap Comparison: ZnO vs GaN Nanowires

ZnO nanowire LEDs feature a direct bandgap of approximately 3.37 eV, which is suitable for UV and visible light emission, while GaN nanowire LEDs have a slightly wider direct bandgap around 3.4 eV, offering efficient emission in the UV to blue spectral range. The close bandgap values allow both ZnO and GaN nanowires to be used for high-performance optoelectronic devices, but GaN nanowires often exhibit superior thermal stability and reduced defects, enhancing LED efficiency and lifespan. Your choice between ZnO and GaN nanowire LEDs should consider the specific emission wavelength requirements and device stability under operational conditions.

Growth Techniques for ZnO and GaN Nanowires

ZnO nanowires are commonly synthesized using low-temperature hydrothermal growth and vapor-liquid-solid (VLS) methods, which offer cost-effective and substrate-compatible advantages. GaN nanowires are typically grown by molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD), enabling high crystalline quality and precise control over doping and composition. The choice of growth technique directly influences defect density, optical properties, and overall device performance in ZnO and GaN nanowire LEDs.

Optical Properties: Emission Efficiency and Wavelength Tuning

ZnO nanowire LEDs exhibit high exciton binding energy and wide bandgap (~3.37 eV), enabling efficient UV emission with easier wavelength tuning via doping and structural modification. GaN nanowire LEDs possess superior thermal stability and high internal quantum efficiency, delivering strong emission in the blue to UV spectrum with more mature wavelength control through alloying with In or Al. Comparative studies reveal ZnO nanowires offer potential for sharper UV emission peaks, while GaN nanowires provide more robust performance in high-power optoelectronic applications.

Electrical Performance: Carrier Injection and Turn-on Voltage

ZnO nanowire LEDs demonstrate efficient carrier injection due to their wide bandgap and high electron mobility, resulting in lower turn-on voltages compared to conventional LEDs. In contrast, GaN nanowire LEDs often require higher turn-on voltages because of their relatively lower carrier injection efficiency despite their robustness in high-power applications. Optimizing your device's electrical performance depends on balancing the lower turn-on voltage advantage of ZnO nanowires with the stable carrier injection characteristics of GaN nanowires.

Fabrication Challenges and Scalability

ZnO nanowire LEDs face fabrication challenges due to difficulty in achieving p-type doping and controlling nanowire uniformity, limiting device efficiency and consistency. GaN nanowire LEDs benefit from more mature epitaxial growth techniques and well-established doping processes, enhancing scalability and yield in commercial production. However, GaN nanowire growth requires high temperatures and complex substrates, increasing fabrication costs compared to ZnO-based devices.

Device Stability and Reliability

ZnO nanowire LEDs often face challenges in device stability due to their susceptibility to surface defects and environmental degradation, which can lead to reduced operational lifetime compared to GaN nanowire LEDs. GaN nanowire LEDs exhibit superior reliability and thermal stability, maintaining consistent performance under high current densities and harsh conditions. To enhance your LED applications, choosing GaN nanowire LEDs ensures better long-term stability and device robustness.

Future Prospects and Applications

ZnO nanowire LEDs offer promising future prospects due to their low-cost fabrication, high electron mobility, and compatibility with flexible substrates, making them ideal for wearable electronics and transparent display technologies. GaN nanowire LEDs exhibit superior efficiency and thermal stability, positioning them as key candidates for high-power optoelectronic devices, solid-state lighting, and next-generation UV light sources. Both materials are critical in advancing nanoscale photonic integration, with ongoing research targeting enhanced device performance and novel applications in IoT and biomedical sensing.

ZnO nanowire LED vs GaN nanowire LED Infographic

electrown.com

electrown.com