Planar waveguides offer low-loss light propagation within a flat, thin film structure ideal for integrated optics, while ridge waveguides provide enhanced mode confinement through etched ridge patterns, improving device performance in photonic circuits. Explore the rest of the article to understand which waveguide type best suits Your optical system needs.

Table of Comparison

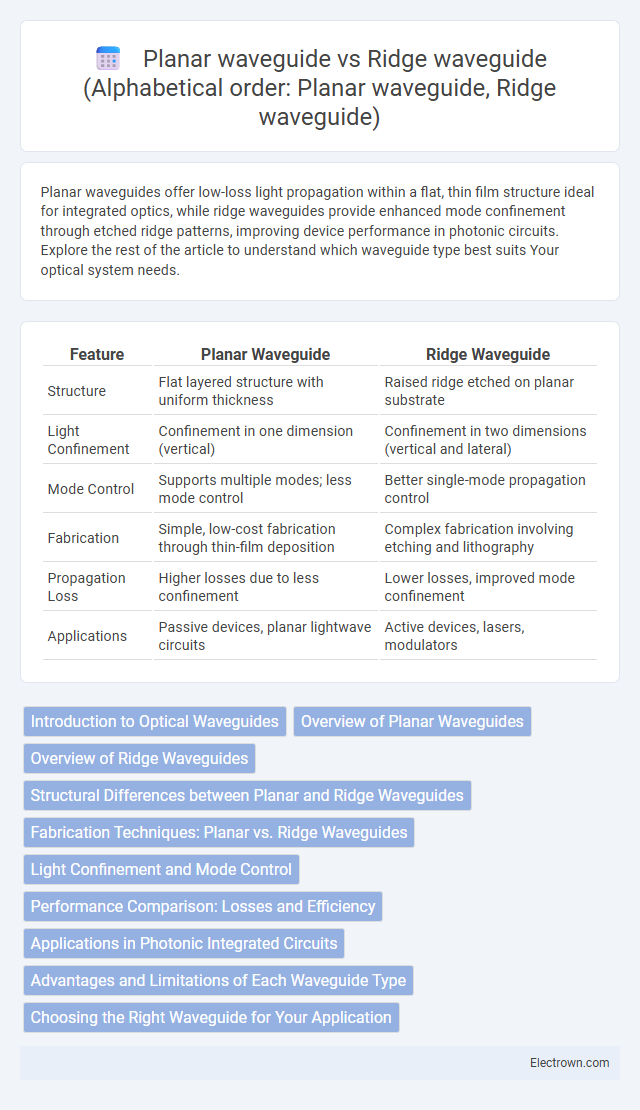

| Feature | Planar Waveguide | Ridge Waveguide |

|---|---|---|

| Structure | Flat layered structure with uniform thickness | Raised ridge etched on planar substrate |

| Light Confinement | Confinement in one dimension (vertical) | Confinement in two dimensions (vertical and lateral) |

| Mode Control | Supports multiple modes; less mode control | Better single-mode propagation control |

| Fabrication | Simple, low-cost fabrication through thin-film deposition | Complex fabrication involving etching and lithography |

| Propagation Loss | Higher losses due to less confinement | Lower losses, improved mode confinement |

| Applications | Passive devices, planar lightwave circuits | Active devices, lasers, modulators |

Introduction to Optical Waveguides

Optical waveguides guide light by confining it within a core material surrounded by a cladding with lower refractive index, enabling efficient signal transmission in photonic devices. Planar waveguides confine light in one dimension, using a flat layer structure ideal for integrated optics, while ridge waveguides provide confinement in two dimensions by etching a ridge on the core layer, enhancing mode control and reducing propagation losses. Your choice between planar and ridge waveguides impacts device performance, integration complexity, and fabrication methods in optical communication systems.

Overview of Planar Waveguides

Planar waveguides consist of a thin, flat layer of high refractive index material sandwiched between lower index layers, enabling light to propagate primarily in two dimensions. These structures are widely used in integrated optics due to their simple fabrication and efficient light confinement over a broad wavelength range. Your choice of planar waveguides supports compact, scalable photonic circuits with low propagation losses suitable for telecommunications and sensing applications.

Overview of Ridge Waveguides

Ridge waveguides consist of a raised strip etched onto a planar substrate, providing strong optical confinement through the refractive index difference between the ridge and surrounding cladding. This structure supports single-mode or multimode propagation with low loss and high fabrication precision, making it ideal for integrated photonic circuits and optical sensors. Ridge waveguides exhibit enhanced mode control and reduced scattering compared to planar waveguides, improving device performance in telecommunications and signal processing applications.

Structural Differences between Planar and Ridge Waveguides

Planar waveguides consist of a thin film layer with a higher refractive index sandwiched between lower-index cladding layers, creating a simple, flat structure that confines light in one dimension. Ridge waveguides incorporate an additional raised ridge on the planar structure, providing lateral confinement and enabling control of light propagation in two dimensions. Your choice depends on the required mode control and fabrication complexity, with ridge waveguides offering enhanced mode confinement and flexibility.

Fabrication Techniques: Planar vs. Ridge Waveguides

Planar waveguides are typically fabricated using thin-film deposition and photolithography on flat substrates, creating uniform layers that guide light in two dimensions. Ridge waveguides involve additional etching processes to form a raised ridge structure, enhancing lateral confinement and enabling tighter mode control. These fabrication differences result in planar waveguides being simpler to manufacture, while ridge waveguides offer improved optical performance at the expense of increased processing complexity.

Light Confinement and Mode Control

Planar waveguides provide broad light confinement with a simple structure, offering limited mode control primarily in the vertical dimension. Ridge waveguides enhance light confinement by introducing lateral index contrast, enabling stronger mode confinement and precise control of lateral modes. Your application benefits from ridge waveguides when tighter mode control and reduced mode dispersion are critical for performance.

Performance Comparison: Losses and Efficiency

Planar waveguides typically exhibit lower propagation losses due to their uniform structure, resulting in higher overall efficiency for integrated photonic circuits. Ridge waveguides, while offering stronger mode confinement and compact design, often experience increased scattering losses at etched sidewalls, which can reduce efficiency in high-precision applications. Optimizing fabrication processes for ridge waveguides can mitigate losses, but planar waveguides remain advantageous for minimizing attenuation in large-scale photonic integration.

Applications in Photonic Integrated Circuits

Planar waveguides enable compact, low-loss light propagation ideal for dense integration in photonic integrated circuits (PICs), supporting multiplexing and optical interconnects in telecommunications and data centers. Ridge waveguides offer enhanced mode confinement and reduced bending losses, making them suitable for high-performance modulators, switches, and lasers within PIC platforms. Both waveguide types drive advances in silicon photonics by optimizing device footprint and optical efficiency tailored to specific integrated circuit functions.

Advantages and Limitations of Each Waveguide Type

Planar waveguides offer low propagation loss and ease of integration with other photonic components, making them ideal for compact optical circuits, but they often suffer from limited mode confinement and higher bending losses. Ridge waveguides provide stronger mode confinement and reduced bending losses, enhancing performance in high-density photonic integrated circuits; however, they require more complex fabrication processes and may exhibit higher scattering losses due to increased sidewall roughness. Your choice between planar and ridge waveguides should balance fabrication complexity against optical performance requirements.

Choosing the Right Waveguide for Your Application

Selecting the right waveguide depends on your application's requirements for mode confinement, fabrication complexity, and propagation loss. Planar waveguides offer low loss and support multiple modes, making them suitable for integrated optics with broad functionalities. Ridge waveguides provide stronger mode confinement and reduced scattering, ideal for high-power or single-mode applications where precise light control is critical.

Planar waveguide vs Ridge waveguide Infographic

electrown.com

electrown.com