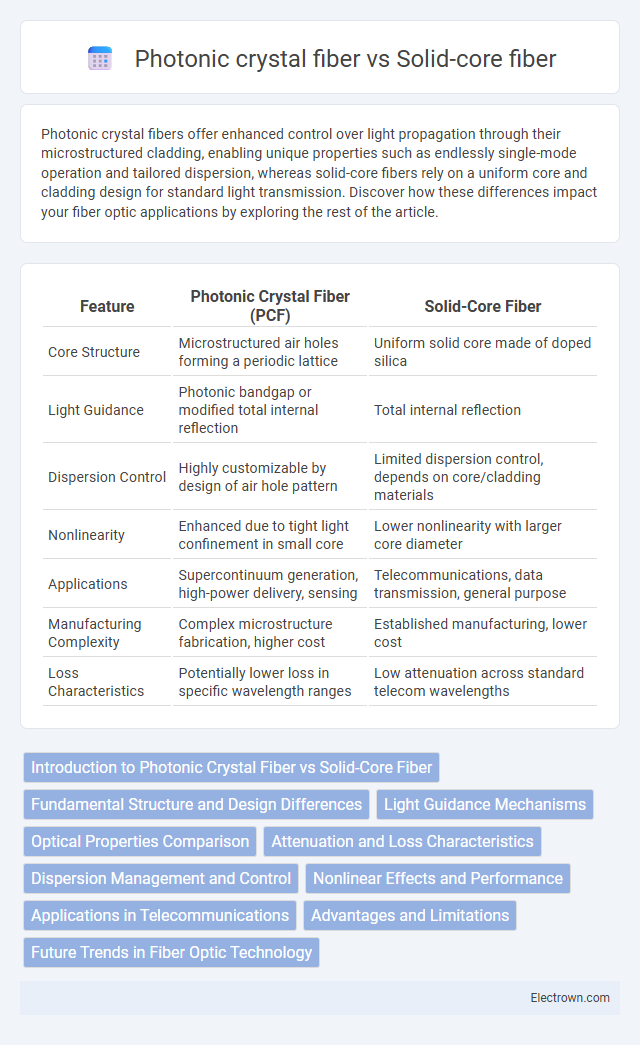

Photonic crystal fibers offer enhanced control over light propagation through their microstructured cladding, enabling unique properties such as endlessly single-mode operation and tailored dispersion, whereas solid-core fibers rely on a uniform core and cladding design for standard light transmission. Discover how these differences impact your fiber optic applications by exploring the rest of the article.

Table of Comparison

| Feature | Photonic Crystal Fiber (PCF) | Solid-Core Fiber |

|---|---|---|

| Core Structure | Microstructured air holes forming a periodic lattice | Uniform solid core made of doped silica |

| Light Guidance | Photonic bandgap or modified total internal reflection | Total internal reflection |

| Dispersion Control | Highly customizable by design of air hole pattern | Limited dispersion control, depends on core/cladding materials |

| Nonlinearity | Enhanced due to tight light confinement in small core | Lower nonlinearity with larger core diameter |

| Applications | Supercontinuum generation, high-power delivery, sensing | Telecommunications, data transmission, general purpose |

| Manufacturing Complexity | Complex microstructure fabrication, higher cost | Established manufacturing, lower cost |

| Loss Characteristics | Potentially lower loss in specific wavelength ranges | Low attenuation across standard telecom wavelengths |

Introduction to Photonic Crystal Fiber vs Solid-Core Fiber

Photonic Crystal Fiber (PCF) leverages a microstructured arrangement of air holes running along its length, enabling unique light guiding properties such as endlessly single-mode operation and tailored dispersion. In contrast, Solid-Core Fiber relies on a uniform glass core with total internal reflection to confine light, offering established performance for telecommunications and sensing. Understanding these fundamental differences helps you choose the optimal fiber type based on applications demanding precise light control or conventional robustness.

Fundamental Structure and Design Differences

Photonic crystal fiber (PCF) features a microstructured arrangement of air holes running along its length, creating a periodic cladding that guides light through photonic bandgap or modified total internal reflection effects. Solid-core fiber, in contrast, has a uniform glass core surrounded by a homogeneous cladding with a lower refractive index, guiding light primarily via total internal reflection. The unique lattice structure of PCF enables tailored dispersion and confinement properties not achievable with conventional solid-core fibers.

Light Guidance Mechanisms

Photonic crystal fibers guide light using a microstructured arrangement of air holes running along their length, which creates a photonic bandgap or modified total internal reflection to confine light within the core. Solid-core fibers rely on total internal reflection between a higher refractive index core and a lower refractive index cladding to direct light efficiently. Understanding these distinct light guidance mechanisms helps you select the optimal fiber type for specific applications like high-power transmission or sensing.

Optical Properties Comparison

Photonic crystal fibers (PCFs) exhibit unique optical properties such as tailorable dispersion, extremely low loss, and high nonlinearity due to their microstructured air-hole cladding, enabling precise control of light propagation and modal confinement. Solid-core fibers, typically made of silica glass, offer well-established, uniform refractive indices and lower nonlinear effects but face limitations in dispersion engineering and mode manipulation. The ability of PCFs to achieve endlessly single-mode operation and customized birefringence provides significant advantages over conventional solid-core fibers in advanced optical communication and sensing applications.

Attenuation and Loss Characteristics

Photonic crystal fibers (PCFs) exhibit significantly lower attenuation and tailored loss characteristics compared to conventional solid-core fibers, due to their unique microstructured air-silica lattice that minimizes scattering and material absorption. PCFs achieve reduced confinement losses by guiding light through photonic bandgap effects or modified total internal reflection, enabling loss figures as low as 0.2 dB/km in optimized designs. In contrast, solid-core fibers typically have attenuation around 0.35 dB/km at telecom wavelengths, primarily limited by Rayleigh scattering and intrinsic material impurities.

Dispersion Management and Control

Photonic crystal fiber (PCF) offers superior dispersion management compared to solid-core fiber due to its unique microstructured design, enabling precise control over chromatic dispersion characteristics. By tailoring the air-hole arrangement within the PCF cladding, you can achieve zero or anomalous dispersion at wavelengths where solid-core fibers typically exhibit high dispersion. This level of dispersion control is critical for applications requiring high bandwidth and minimal pulse broadening, such as ultrafast optics and high-speed communication systems.

Nonlinear Effects and Performance

Photonic crystal fibers (PCFs) exhibit significantly enhanced nonlinear effects compared to solid-core fibers due to their unique microstructured air-hole cladding, allowing precise control over light confinement and dispersion. This structural advantage enables PCFs to achieve higher nonlinear coefficients, improving performance in supercontinuum generation and nonlinear optical signal processing. Your choice of fiber impacts performance metrics, with PCFs offering superior control over nonlinear interactions for advanced photonics applications.

Applications in Telecommunications

Photonic crystal fibers (PCFs) offer enhanced dispersion control and low nonlinearity, making them ideal for high-capacity, long-distance telecommunications systems that demand minimal signal distortion. Solid-core fibers remain the industry standard due to their proven reliability and cost-effectiveness in widespread data transmission networks. Your choice between PCF and solid-core fiber in telecommunications depends on the need for specialized performance versus established infrastructure compatibility.

Advantages and Limitations

Photonic crystal fiber offers superior light guidance with customizable dispersion properties and high nonlinearity, enabling enhanced performance in applications like sensing and nonlinear optics. Solid-core fiber provides well-established, low-loss transmission with stable modal properties, making it ideal for widespread telecommunications and everyday optical systems. Limitations of photonic crystal fiber include complex fabrication and higher attenuation, while solid-core fiber struggles with limited design flexibility and lower nonlinear interaction.

Future Trends in Fiber Optic Technology

Photonic crystal fibers (PCFs) offer unprecedented control over light propagation through their microstructured cladding, enabling innovations in nonlinear optics, sensing, and broadband communication. Solid-core fibers, while entrenched in current infrastructure, face limitations in bandwidth and dispersion control that PCFs are addressing with tailored designs and improved material incorporation. Your future investments in fiber optic technology stand to benefit from the enhanced flexibility and performance PCFs provide, paving the way for next-generation high-speed networks and advanced photonic devices.

Photonic crystal fiber vs Solid-core fiber Infographic

electrown.com

electrown.com