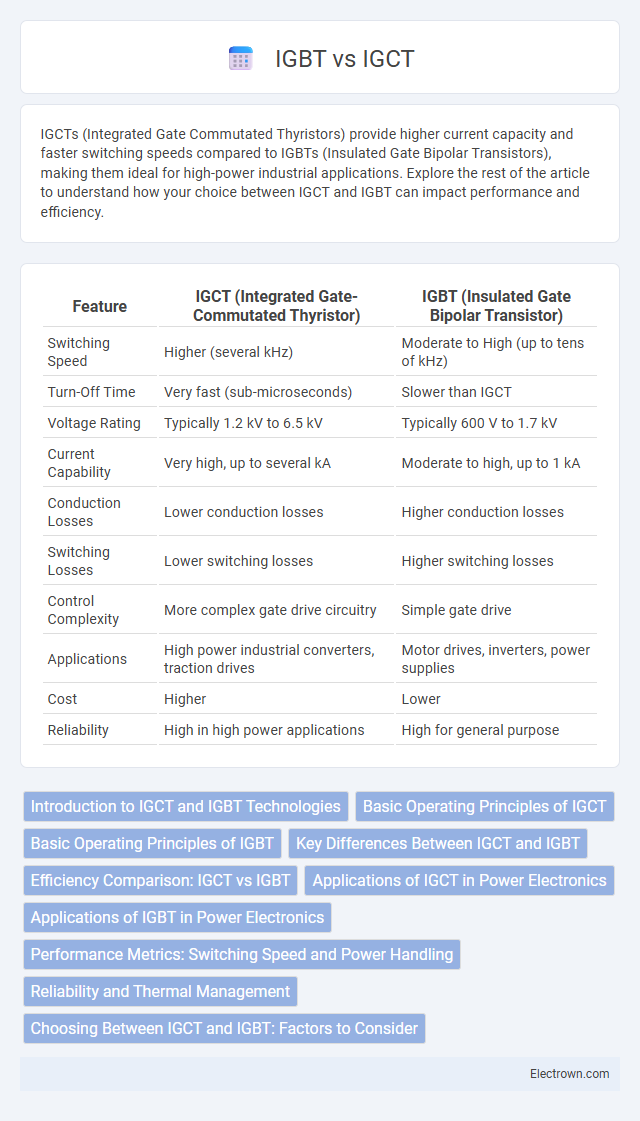

IGCTs (Integrated Gate Commutated Thyristors) provide higher current capacity and faster switching speeds compared to IGBTs (Insulated Gate Bipolar Transistors), making them ideal for high-power industrial applications. Explore the rest of the article to understand how your choice between IGCT and IGBT can impact performance and efficiency.

Table of Comparison

| Feature | IGCT (Integrated Gate-Commutated Thyristor) | IGBT (Insulated Gate Bipolar Transistor) |

|---|---|---|

| Switching Speed | Higher (several kHz) | Moderate to High (up to tens of kHz) |

| Turn-Off Time | Very fast (sub-microseconds) | Slower than IGCT |

| Voltage Rating | Typically 1.2 kV to 6.5 kV | Typically 600 V to 1.7 kV |

| Current Capability | Very high, up to several kA | Moderate to high, up to 1 kA |

| Conduction Losses | Lower conduction losses | Higher conduction losses |

| Switching Losses | Lower switching losses | Higher switching losses |

| Control Complexity | More complex gate drive circuitry | Simple gate drive |

| Applications | High power industrial converters, traction drives | Motor drives, inverters, power supplies |

| Cost | Higher | Lower |

| Reliability | High in high power applications | High for general purpose |

Introduction to IGCT and IGBT Technologies

IGCT (Integrated Gate-Commutated Thyristor) and IGBT (Insulated Gate Bipolar Transistor) are power semiconductor devices widely used in high-power applications. IGCTs offer high current carrying capability and fast switching speeds, making them suitable for industrial drives and power conversion systems. IGBTs combine MOSFET input characteristics with bipolar transistor output, providing efficiency and ease of control in medium to high voltage inverters and motor control units.

Basic Operating Principles of IGCT

The Integrated Gate-Commutated Thyristor (IGCT) operates by combining the gate triggering capability of an IGBT with the thyristor's high current and voltage handling capacity, enabling rapid turn-off and turn-on. It uses a gate pulse to inject carriers and switch the device on, then applies a strong reverse gate current to turn off the thyristor, facilitating high-speed commutation. IGCTs provide low conduction loss like thyristors and high switching speed similar to IGBTs, making them ideal for high-power industrial applications.

Basic Operating Principles of IGBT

IGBT (Insulated Gate Bipolar Transistor) operates by combining the high input impedance and fast switching of a MOSFET with the high current and low saturation voltage capability of a bipolar transistor, enabling efficient control of large power. It uses a gate terminal to control the flow of carriers through a semiconductor structure composed of n- and p-type layers, allowing it to switch between conductive and non-conductive states rapidly. This unique operation principle makes IGBTs highly suitable for medium- to high-power applications requiring fast switching and low conduction losses.

Key Differences Between IGCT and IGBT

IGCT (Integrated Gate Commutated Thyristor) offers faster switching speeds and higher current handling capabilities compared to IGBT (Insulated Gate Bipolar Transistor), making IGCTs ideal for high-power industrial applications. IGBTs provide better efficiency and lower conduction losses at medium voltage ranges, widely used in renewable energy and electric vehicles. IGCTs require complex gate drive circuits while IGBTs use simpler gate control, influencing their application and system design choices.

Efficiency Comparison: IGCT vs IGBT

IGCTs (Integrated Gate-Commutated Thyristors) offer higher efficiency than IGBTs (Insulated Gate Bipolar Transistors) in high-power applications due to their lower conduction and switching losses, especially at megawatt-level power ratings. IGCTs demonstrate superior thermal performance and current carrying capabilities, enabling reduced cooling requirements and enhanced reliability in industrial drives and power conversion systems. IGBTs, while efficient at medium power ranges, experience greater switching losses and reduced efficiency in ultra-high power applications compared to IGCTs.

Applications of IGCT in Power Electronics

IGCTs (Integrated Gate-Commutated Thyristors) excel in high-power applications such as industrial motor drives, traction systems, and power grid converters due to their fast switching capabilities and low conduction losses. Their robustness and ability to handle high voltage and current make IGCTs ideal for large-scale power electronics where efficiency and durability are critical. If your project demands superior performance in high-voltage environments, IGCTs offer a reliable solution compared to traditional IGBTs.

Applications of IGBT in Power Electronics

IGBTs are widely used in power electronics for applications such as motor drives, inverters, and power supplies due to their high efficiency and fast switching capabilities. Their ability to handle high voltage and current makes them ideal for renewable energy systems, electric vehicles, and industrial automation. The combination of MOSFET and bipolar transistor features in IGBTs enables reliable performance in medium- to high-power applications.

Performance Metrics: Switching Speed and Power Handling

IGBTs offer high power handling with moderate switching speeds, making them suitable for applications requiring efficient energy transfer in medium to high voltage ranges. IGCTs excel in ultra-fast switching speeds combined with high power capabilities, delivering superior performance in high-frequency and high-power industrial environments. Your choice depends on whether prioritizing rapid switching for dynamic control or robust power handling for heavy loads is more critical.

Reliability and Thermal Management

IGBTs offer proven reliability with well-established thermal management techniques, making them a preferred choice for applications requiring consistent performance under thermal stress. IGCTs provide superior power handling and faster switching speeds but demand advanced cooling solutions to manage higher heat dissipation effectively. Your selection between IGCT and IGBT should consider the balance between reliability needs and the complexity of thermal management in your specific application.

Choosing Between IGCT and IGBT: Factors to Consider

Choosing between IGCT and IGBT depends on factors such as switching speed, voltage and current ratings, and thermal performance. IGCTs offer faster switching capabilities and higher current handling, making them suitable for high-power industrial applications like motor drives and traction systems. IGBTs provide cost-effective solutions with simpler gate drive requirements, ideal for medium-voltage applications and inverters where efficiency and reliability are key.

igct vs igbt Infographic

electrown.com

electrown.com