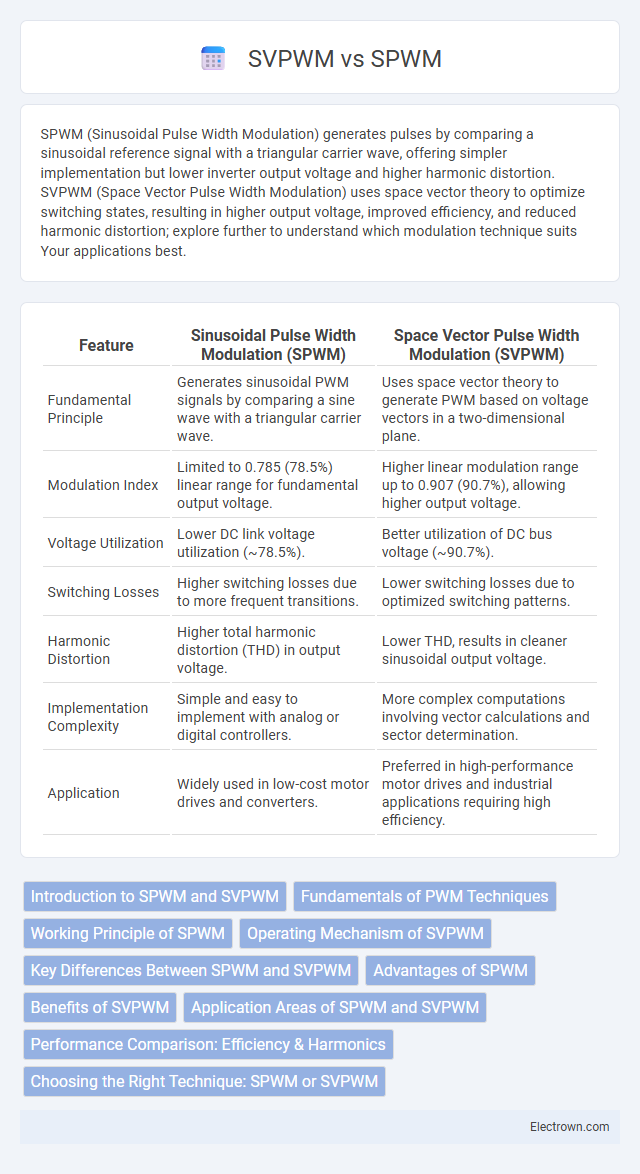

SPWM (Sinusoidal Pulse Width Modulation) generates pulses by comparing a sinusoidal reference signal with a triangular carrier wave, offering simpler implementation but lower inverter output voltage and higher harmonic distortion. SVPWM (Space Vector Pulse Width Modulation) uses space vector theory to optimize switching states, resulting in higher output voltage, improved efficiency, and reduced harmonic distortion; explore further to understand which modulation technique suits Your applications best.

Table of Comparison

| Feature | Sinusoidal Pulse Width Modulation (SPWM) | Space Vector Pulse Width Modulation (SVPWM) |

|---|---|---|

| Fundamental Principle | Generates sinusoidal PWM signals by comparing a sine wave with a triangular carrier wave. | Uses space vector theory to generate PWM based on voltage vectors in a two-dimensional plane. |

| Modulation Index | Limited to 0.785 (78.5%) linear range for fundamental output voltage. | Higher linear modulation range up to 0.907 (90.7%), allowing higher output voltage. |

| Voltage Utilization | Lower DC link voltage utilization (~78.5%). | Better utilization of DC bus voltage (~90.7%). |

| Switching Losses | Higher switching losses due to more frequent transitions. | Lower switching losses due to optimized switching patterns. |

| Harmonic Distortion | Higher total harmonic distortion (THD) in output voltage. | Lower THD, results in cleaner sinusoidal output voltage. |

| Implementation Complexity | Simple and easy to implement with analog or digital controllers. | More complex computations involving vector calculations and sector determination. |

| Application | Widely used in low-cost motor drives and converters. | Preferred in high-performance motor drives and industrial applications requiring high efficiency. |

Introduction to SPWM and SVPWM

SPWM (Sinusoidal Pulse Width Modulation) and SVPWM (Space Vector Pulse Width Modulation) are advanced techniques used to control voltage and current in inverters for efficient motor drives. SPWM generates sinusoidal voltage waveforms by modulating the pulse width of a carrier signal, while SVPWM optimizes the inverter switching states to produce a higher voltage output with less harmonic distortion. Your choice between these methods impacts the performance, efficiency, and smoothness of electrical motor operations.

Fundamentals of PWM Techniques

SPWM (Sinusoidal Pulse Width Modulation) generates output voltages by comparing a sinusoidal reference signal with a triangular carrier wave, producing a sinusoidal waveform with variable frequency and amplitude ideal for controlling AC motors. SVPWM (Space Vector Pulse Width Modulation) enhances performance by representing three-phase voltages as a space vector in a two-dimensional plane, optimizing voltage utilization and reducing harmonic distortion compared to SPWM. Choosing between SPWM and SVPWM impacts your system's efficiency and waveform quality, with SVPWM offering superior control in high-performance inverter applications.

Working Principle of SPWM

SPWM (Sinusoidal Pulse Width Modulation) works by comparing a sinusoidal reference signal with a high-frequency triangular carrier wave to generate pulse widths corresponding to the sine wave's amplitude. This method modulates the inverter's output voltage by varying the duty cycle of each pulse, producing a waveform that approximates a pure sine wave. Your motor drives benefit from SPWM through reduced harmonic distortion and improved voltage control.

Operating Mechanism of SVPWM

Space Vector Pulse Width Modulation (SVPWM) operates by representing three-phase voltages as a rotating space vector in a two-dimensional coordinate system, optimizing the switching states of the inverter. SVPWM divides the voltage space into six sectors and calculates the time duration for each active and zero vector to produce a reference voltage vector that maximizes DC bus utilization. This approach reduces harmonic distortion and improves motor efficiency compared to Sinusoidal Pulse Width Modulation (SPWM).

Key Differences Between SPWM and SVPWM

SPWM (Sinusoidal Pulse Width Modulation) generates pulses by comparing a sinusoidal reference signal with a triangular carrier wave, producing a line-to-neutral voltage waveform, whereas SVPWM (Space Vector Pulse Width Modulation) synthesizes voltage vectors in a two-dimensional plane to optimize the output voltage and reduce harmonic distortion. SVPWM offers higher DC bus utilization and improved harmonic performance compared to SPWM, making it more efficient for controlling three-phase inverters in motor drives. Your choice between SPWM and SVPWM can impact inverter efficiency, output quality, and overall system performance.

Advantages of SPWM

Sinusoidal Pulse Width Modulation (SPWM) offers simpler implementation and easier control compared to Space Vector PWM (SVPWM), making it ideal for low- and medium-power inverter applications. SPWM provides lower harmonic distortion in output voltage at fundamental switching frequencies, improving motor performance and efficiency. This technique also requires less computational complexity, reducing the cost and design effort in DC-AC inverter systems.

Benefits of SVPWM

Space Vector Pulse Width Modulation (SVPWM) offers improved DC bus voltage utilization and reduced harmonic distortion compared to Sinusoidal Pulse Width Modulation (SPWM). SVPWM generates higher output voltage with better waveform quality, leading to enhanced motor efficiency and smoother torque generation. Your drive system benefits from lower switching losses and increased dynamic response, making SVPWM the preferred choice for modern motor control applications.

Application Areas of SPWM and SVPWM

SPWM (Sinusoidal Pulse Width Modulation) is widely used in low-power motor drives, uninterruptible power supplies, and simple inverter circuits due to its straightforward implementation and good harmonic performance. SVPWM (Space Vector Pulse Width Modulation) is preferred in high-performance industrial drives, electric vehicle inverters, and renewable energy systems owing to its superior DC bus utilization, reduced harmonic distortion, and enhanced torque control. Both modulation techniques optimize power electronics applications, but SVPWM is the choice for advanced, high-efficiency systems requiring precise voltage vector control.

Performance Comparison: Efficiency & Harmonics

Space Vector Pulse Width Modulation (SVPWM) offers higher efficiency than Sinusoidal Pulse Width Modulation (SPWM) by utilizing the DC bus voltage more effectively, resulting in increased output voltage and reduced switching losses. SVPWM generates lower harmonic distortion with a total harmonic distortion (THD) typically 2-5% less than SPWM, improving motor performance and reducing acoustic noise. The superior harmonic profile and efficiency of SVPWM make it the preferred choice for high-performance inverter applications in industrial motor drives.

Choosing the Right Technique: SPWM or SVPWM

Selecting the appropriate modulation technique between Sinusoidal Pulse Width Modulation (SPWM) and Space Vector Pulse Width Modulation (SVPWM) depends on efficiency and harmonic performance criteria. SVPWM offers higher DC bus utilization and lower total harmonic distortion compared to SPWM, making it ideal for applications requiring improved power quality and motor control precision. SPWM remains suitable for simpler systems due to its straightforward implementation and lower computational requirements.

SPWM vs SVPWM Infographic

electrown.com

electrown.com