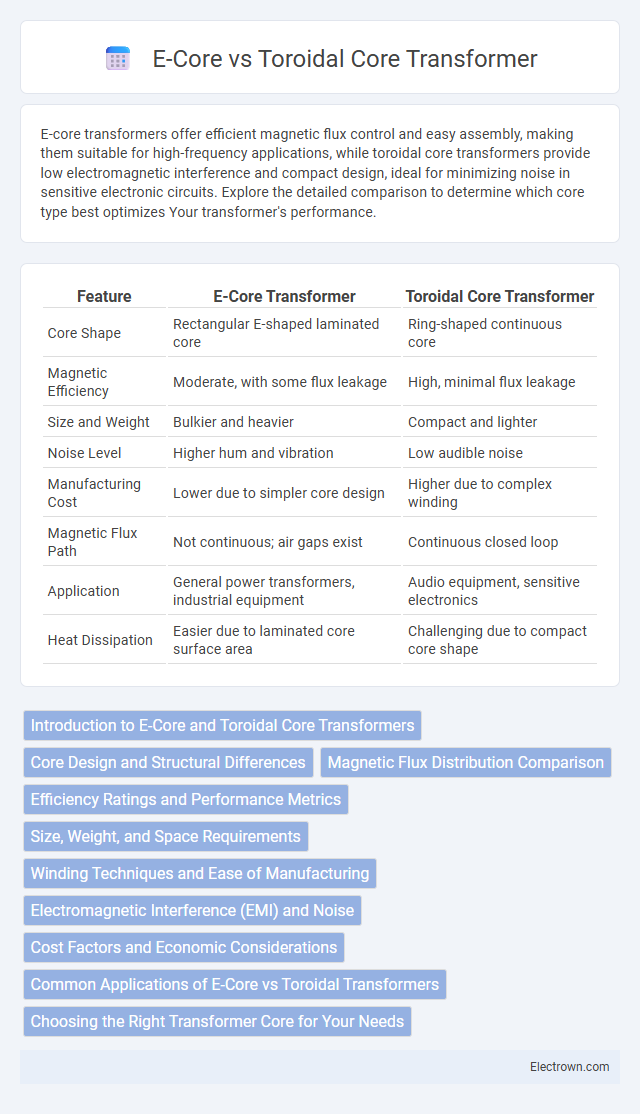

E-core transformers offer efficient magnetic flux control and easy assembly, making them suitable for high-frequency applications, while toroidal core transformers provide low electromagnetic interference and compact design, ideal for minimizing noise in sensitive electronic circuits. Explore the detailed comparison to determine which core type best optimizes Your transformer's performance.

Table of Comparison

| Feature | E-Core Transformer | Toroidal Core Transformer |

|---|---|---|

| Core Shape | Rectangular E-shaped laminated core | Ring-shaped continuous core |

| Magnetic Efficiency | Moderate, with some flux leakage | High, minimal flux leakage |

| Size and Weight | Bulkier and heavier | Compact and lighter |

| Noise Level | Higher hum and vibration | Low audible noise |

| Manufacturing Cost | Lower due to simpler core design | Higher due to complex winding |

| Magnetic Flux Path | Not continuous; air gaps exist | Continuous closed loop |

| Application | General power transformers, industrial equipment | Audio equipment, sensitive electronics |

| Heat Dissipation | Easier due to laminated core surface area | Challenging due to compact core shape |

Introduction to E-Core and Toroidal Core Transformers

E-core transformers feature a laminated core shaped like the letter "E," optimizing magnetic flux paths and minimizing core losses for efficient energy transfer in power supplies and audio applications. Toroidal core transformers use a continuous ring-shaped core made from silicon steel or ferrite, providing higher efficiency and reduced electromagnetic interference due to uniform magnetic flux distribution. Both core types are integral in transformer design, influencing performance characteristics such as size, noise level, and thermal management.

Core Design and Structural Differences

E-core transformers feature a laminated iron core shaped like the letter "E," enabling easier winding placement and efficient magnetic flux distribution, while toroidal core transformers utilize a continuous ring-shaped core made of a thin strip of silicon steel, offering minimal core losses and reduced electromagnetic interference. The E-core design provides straightforward assembly and better mechanical stability, whereas the toroidal core's closed-loop structure ensures superior efficiency and compact size. Choosing between these cores influences your transformer's performance, size, and electromagnetic characteristics based on the specific application requirements.

Magnetic Flux Distribution Comparison

E-core transformers exhibit a more uniform magnetic flux distribution due to their closed magnetic path formed by the E-shaped core, minimizing leakage flux and enhancing efficiency. Toroidal core transformers provide superior magnetic flux confinement with a continuous circular core, reducing core losses and electromagnetic interference more effectively than E-cores. Understanding these differences in magnetic flux distribution helps you select the appropriate transformer type for optimizing performance and minimizing energy loss in your application.

Efficiency Ratings and Performance Metrics

E-core transformers exhibit high efficiency ratings due to their compact design and lower core losses, making them suitable for applications requiring consistent performance under varying loads. Toroidal core transformers often deliver superior efficiency with reduced electromagnetic interference and better thermal dissipation, enhancing overall performance metrics in sensitive electronic circuits. Your choice depends on balancing efficiency needs with space constraints and specific application requirements.

Size, Weight, and Space Requirements

E-core transformers are generally more compact and lightweight compared to toroidal core transformers, making them ideal for applications with limited space. Toroidal core transformers feature a circular core design that provides superior magnetic efficiency but typically results in a heavier and bulkier unit. Your choice between the two should consider the balance between size constraints and performance needs, as toroidal cores may require more installation space despite their electrical advantages.

Winding Techniques and Ease of Manufacturing

E-core transformers typically feature simpler winding techniques due to their rectangular core limbs, facilitating automated winding processes and reducing manufacturing complexity. Toroidal core transformers require precision winding around a circular core, often demanding skilled manual labor or specialized machinery to maintain uniform tension and tight coil layering. The ease of manufacturing E-core transformers generally results in lower production costs and faster turnaround times compared to the more intricate winding process of toroidal cores.

Electromagnetic Interference (EMI) and Noise

E-core transformers typically exhibit higher electromagnetic interference (EMI) due to their open magnetic path, which allows more leakage flux and noise emissions compared to toroidal cores. Toroidal core transformers offer superior EMI suppression and lower noise levels because their continuous, closed-loop magnetic path minimizes flux leakage and electromagnetic radiation. The reduced EMI in toroidal cores makes them ideal for sensitive electronic applications requiring quiet operation and minimal interference.

Cost Factors and Economic Considerations

E-core transformers generally offer lower manufacturing costs due to simpler lamination stacking and standardized core shapes, making them cost-effective for high-volume production. Toroidal core transformers, while more expensive due to complex winding processes and higher material costs, provide superior efficiency and reduced electromagnetic interference, which can lower operating expenses over time. Evaluating total cost of ownership involves balancing initial expenditure against energy savings and application-specific performance benefits.

Common Applications of E-Core vs Toroidal Transformers

E-core transformers are widely used in power supplies, audio equipment, and general industrial applications due to their robust construction and efficient magnetic flux handling. Toroidal transformers find common applications in medical devices, precision instrumentation, and audio amplifiers because of their low electromagnetic interference and compact design. Both types serve critical roles in electrical circuits, with e-core preferred for high power and cost efficiency, while toroidal cores excel in noise-sensitive and space-constrained environments.

Choosing the Right Transformer Core for Your Needs

Selecting between e-core and toroidal core transformers hinges on factors such as efficiency, size, and electromagnetic interference (EMI). Toroidal cores offer higher efficiency, compact size, and reduced EMI due to their closed-loop design, making them ideal for sensitive electronics and space-constrained applications. E-core transformers, while larger and less efficient, are more cost-effective and easier to manufacture, suiting applications where budget and robustness are prioritized over compactness.

e-core vs toroidal core transformer Infographic

electrown.com

electrown.com