Pulse tube refrigerators offer robust, vibration-free cooling ideal for applications requiring maintenance-free operation at temperatures around 3-4 K, while dilution refrigerators achieve ultra-low temperatures below 10 mK, essential for quantum computing and fundamental physics research. Explore the full comparison to determine which refrigeration technology best fits your scientific or industrial needs.

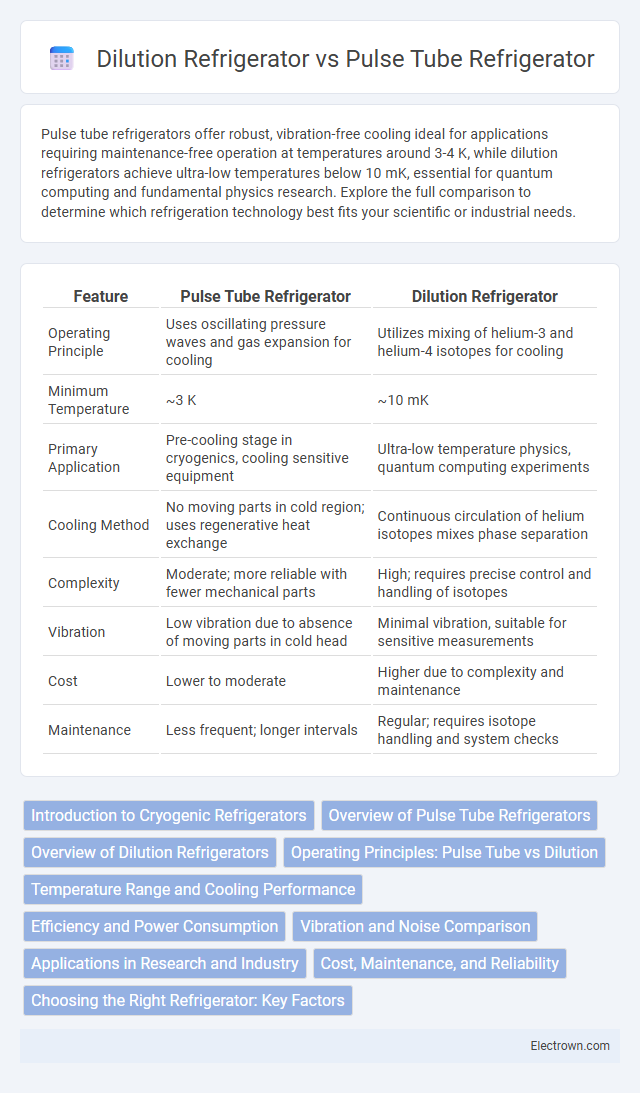

Table of Comparison

| Feature | Pulse Tube Refrigerator | Dilution Refrigerator |

|---|---|---|

| Operating Principle | Uses oscillating pressure waves and gas expansion for cooling | Utilizes mixing of helium-3 and helium-4 isotopes for cooling |

| Minimum Temperature | ~3 K | ~10 mK |

| Primary Application | Pre-cooling stage in cryogenics, cooling sensitive equipment | Ultra-low temperature physics, quantum computing experiments |

| Cooling Method | No moving parts in cold region; uses regenerative heat exchange | Continuous circulation of helium isotopes mixes phase separation |

| Complexity | Moderate; more reliable with fewer mechanical parts | High; requires precise control and handling of isotopes |

| Vibration | Low vibration due to absence of moving parts in cold head | Minimal vibration, suitable for sensitive measurements |

| Cost | Lower to moderate | Higher due to complexity and maintenance |

| Maintenance | Less frequent; longer intervals | Regular; requires isotope handling and system checks |

Introduction to Cryogenic Refrigerators

Pulse tube refrigerators and dilution refrigerators serve critical roles in cryogenic cooling, each optimized for distinct temperature ranges and applications. Pulse tube refrigerators achieve temperatures typically around 3-4 K using oscillating gas pressure without moving parts at the cold end, enhancing reliability and minimizing vibrations. Dilution refrigerators reach millikelvin temperatures by exploiting the phase separation of helium-3 and helium-4 isotopes, making them essential in quantum computing and ultra-low temperature physics research.

Overview of Pulse Tube Refrigerators

Pulse tube refrigerators utilize oscillating gas pressures and a regenerator to achieve cooling without moving parts in the cold region, resulting in high reliability and low vibration. They typically reach temperatures around 3 to 4 Kelvin, making them ideal for applications requiring cryogenic cooling above 1 Kelvin. Pulse tube refrigerators are widely used in fields such as superconducting electronics, infrared sensors, and medical imaging due to their compact design and maintenance-free operation.

Overview of Dilution Refrigerators

Dilution refrigerators utilize a mixture of helium-3 and helium-4 isotopes to achieve temperatures below 10 millikelvin, essential for quantum computing and ultra-sensitive scientific experiments. Unlike pulse tube refrigerators, which primarily provide cooling down to a few kelvins through gas compression and expansion cycles, dilution refrigerators rely on the enthalpy of mixing in the helium isotopes for continuous cooling at millikelvin ranges. Your choice of a dilution refrigerator enables ultra-low temperature environments critical for exploring quantum phenomena and conducting advanced cryogenic research.

Operating Principles: Pulse Tube vs Dilution

Pulse tube refrigerators operate based on oscillating pressure and gas expansion and compression cycles within a closed loop, using a pulse tube to transfer heat without moving parts at the cold end, enhancing reliability and reducing vibrations. Dilution refrigerators function by exploiting the mixing of helium-3 and helium-4 isotopes at ultra-low temperatures, where the endothermic dilution process absorbs heat and achieves temperatures below 10 millikelvin. The fundamental difference lies in pulse tube refrigeration relying on thermodynamic gas cycles, whereas dilution refrigeration utilizes quantum phase separation and isotope mixing for ultra-cold cooling.

Temperature Range and Cooling Performance

Pulse tube refrigerators achieve temperatures typically down to around 3-4 K with efficient cooling power suitable for many cryogenic applications. Dilution refrigerators, however, reach much lower temperatures, often below 10 mK, making them ideal for experiments requiring ultra-low thermal noise and extreme cooling performance. Your choice depends on the required temperature range and cooling efficiency for your specific scientific or industrial needs.

Efficiency and Power Consumption

Pulse tube refrigerators offer higher efficiency at moderate cooling powers, utilizing minimal moving parts to reduce mechanical losses and power consumption. Dilution refrigerators achieve ultra-low temperatures necessary for quantum applications but demand significantly more power due to continuous circulation of helium isotopes and complex refrigeration cycles. Your choice depends on balancing efficiency needs with the low-temperature requirements of your specific application.

Vibration and Noise Comparison

Pulse tube refrigerators generate lower mechanical vibrations than traditional Stirling or Gifford-McMahon coolers but still cause more vibration compared to dilution refrigerators, which involve no moving parts inside the cryostat. Dilution refrigerators operate silently with minimal vibrations, making them ideal for experiments requiring ultra-low noise environments. Your choice depends on whether minimizing vibration and acoustic noise is critical for sensitive measurements at millikelvin temperatures.

Applications in Research and Industry

Pulse tube refrigerators excel in cryogenic cooling for superconducting electronics, infrared sensors, and small-scale quantum experiments due to their vibration-free operation and reliability. Dilution refrigerators achieve ultra-low temperatures below 10 millikelvin, crucial for advanced quantum computing research, condensed matter physics, and nanoscale device characterization. Both technologies play pivotal roles in scientific and industrial advancements, with pulse tubes favored for moderately low temperatures and dilution refrigerators indispensable for reaching deep cryogenic regimes.

Cost, Maintenance, and Reliability

Pulse tube refrigerators generally have lower initial costs, reduced maintenance requirements, and higher reliability due to their fewer moving parts and lack of liquid helium handling compared to dilution refrigerators. Dilution refrigerators, while offering lower temperatures ideal for quantum computing applications, involve higher operational costs and complex maintenance due to the continuous circulation of helium-3/helium-4 mixtures and mechanical pumps. The reliability of pulse tube systems makes them favorable for applications requiring consistent cooling with minimal downtime, whereas dilution refrigerators require expert handling and more frequent servicing to maintain optimal performance.

Choosing the Right Refrigerator: Key Factors

Selecting between a pulse tube refrigerator and a dilution refrigerator depends on cooling temperature requirements and application precision. Pulse tube refrigerators efficiently achieve temperatures around 3-4 K for general cryogenic cooling, while dilution refrigerators reach millikelvin ranges essential for quantum computing and ultra-sensitive experiments. Consider factors such as cooling power, vibration levels, maintenance complexity, and operational cost to match the refrigerator with the specific scientific or industrial application.

pulse tube refrigerator vs dilution refrigerator Infographic

electrown.com

electrown.com