Coplanar waveguide (CPW) offers advantages such as easier integration with active devices and reduced radiation loss compared to microstrip, which is favored for its simpler fabrication and well-established modeling. Understanding these differences helps optimize your high-frequency circuit design, so continue reading to explore their detailed characteristics and applications.

Table of Comparison

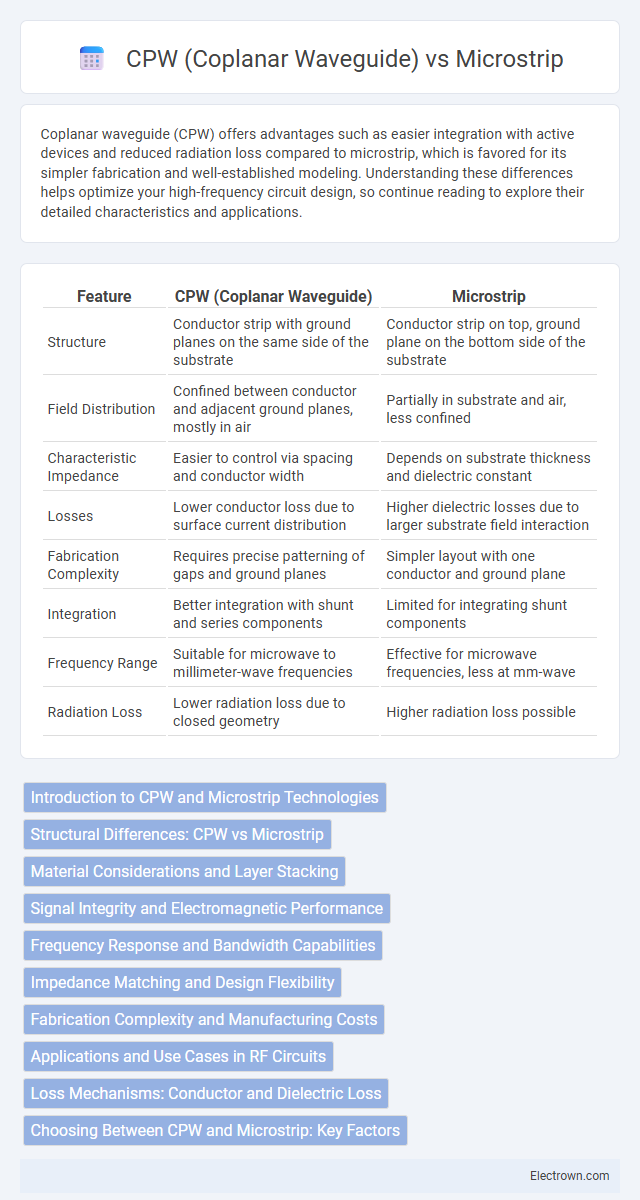

| Feature | CPW (Coplanar Waveguide) | Microstrip |

|---|---|---|

| Structure | Conductor strip with ground planes on the same side of the substrate | Conductor strip on top, ground plane on the bottom side of the substrate |

| Field Distribution | Confined between conductor and adjacent ground planes, mostly in air | Partially in substrate and air, less confined |

| Characteristic Impedance | Easier to control via spacing and conductor width | Depends on substrate thickness and dielectric constant |

| Losses | Lower conductor loss due to surface current distribution | Higher dielectric losses due to larger substrate field interaction |

| Fabrication Complexity | Requires precise patterning of gaps and ground planes | Simpler layout with one conductor and ground plane |

| Integration | Better integration with shunt and series components | Limited for integrating shunt components |

| Frequency Range | Suitable for microwave to millimeter-wave frequencies | Effective for microwave frequencies, less at mm-wave |

| Radiation Loss | Lower radiation loss due to closed geometry | Higher radiation loss possible |

Introduction to CPW and Microstrip Technologies

Coplanar waveguide (CPW) and microstrip are widely used transmission line technologies in high-frequency circuit design, each featuring distinct structural configurations affecting signal integrity and integration. CPW consists of a single conductor flanked by two ground planes on the same dielectric surface, offering reduced radiation loss and easier shunt or series component integration compared to the microstrip, which consists of a conductor strip separated from the ground plane by a dielectric substrate. Your choice between CPW and microstrip impacts impedance control, substrate utilization, and fabrication complexity, crucial for optimizing RF and microwave circuit performance.

Structural Differences: CPW vs Microstrip

CPW (coplanar waveguide) features a central conductor flanked by two ground planes on the same substrate surface, enabling easy integration with surface-mounted components and simplifying fabrication. In contrast, a microstrip line consists of a single conductor separated from a continuous ground plane by a dielectric substrate, resulting in different electromagnetic field distributions. Your choice between CPW and microstrip depends on manufacturing constraints and signal integrity requirements due to their distinct structural configurations.

Material Considerations and Layer Stacking

CPW (coplanar waveguide) structures typically require a single-layer dielectric substrate with a patterned ground plane and signal conductor on the same side, which simplifies material selection and reduces complexity in layer stacking. Microstrip configurations demand a multilayer approach, with the signal conductor on the top layer and a continuous ground plane beneath a dielectric substrate, necessitating precise control of substrate thickness and dielectric constant to optimize impedance and signal integrity. The choice of substrate materials such as Rogers RT/duroid or FR4 significantly impacts loss tangent and dielectric constant, influencing propagation loss and dispersion characteristics in both CPW and microstrip designs.

Signal Integrity and Electromagnetic Performance

Coplanar waveguide (CPW) exhibits superior signal integrity due to its reduced dispersion and lower radiation loss compared to microstrip lines, which often suffer from substrate leakage and higher dielectric losses. The symmetric structure of CPW enhances electromagnetic performance by confining the fields primarily between the signal conductor and adjacent ground planes, resulting in improved impedance control and reduced crosstalk. Microstrip lines, although easier to fabricate, typically present higher signal attenuation and sensitivity to substrate variations, impacting high-frequency performance in RF and microwave circuits.

Frequency Response and Bandwidth Capabilities

CPW (coplanar waveguide) offers superior high-frequency performance with reduced dispersion and radiation losses compared to microstrip, making it ideal for ultra-wideband applications. Its symmetrical structure ensures consistent impedance and minimizes parasitic effects, enhancing bandwidth capabilities beyond typical microstrip lines. Your designs requiring broad frequency response and stable signal integrity benefit significantly from CPW's inherent advantages.

Impedance Matching and Design Flexibility

CPW (coplanar waveguide) offers superior impedance matching due to its symmetric structure and easy integration with surface-mounted devices, minimizing parasitic effects and signal loss. Microstrip lines provide greater design flexibility with simpler multilayer PCB implementation and wider availability of manufacturing processes, but can suffer from less precise impedance control due to substrate variations. Your choice depends on whether accuracy in impedance matching or ease of integration and layout adaptability takes priority in your RF circuit design.

Fabrication Complexity and Manufacturing Costs

Coplanar waveguides (CPW) offer simpler fabrication as the signal conductor and ground planes reside on the same substrate surface, reducing layer alignment challenges and etching steps compared to microstrip lines, which require a dielectric layer and a separate ground plane on the substrate's opposite side. Manufacturing costs for CPW are generally lower due to fewer fabrication steps and compatibility with standard planar processing techniques, while microstrip fabrication incurs additional expenses from multilayer substrate processing and precise dielectric thickness control. These factors make CPW preferable for cost-sensitive, high-frequency applications requiring streamlined production and consistent performance.

Applications and Use Cases in RF Circuits

CPW (coplanar waveguide) is widely used in high-frequency RF circuits requiring easy access to ground and reduced radiation losses, making it ideal for on-chip integration and millimeter-wave applications. Microstrip lines are preferred in printed circuit boards for their simple fabrication and effective performance in low- to mid-frequency ranges, commonly seen in antennas, filters, and amplifiers. Your choice between CPW and microstrip depends on power handling, operating frequency, and integration needs in your RF design.

Loss Mechanisms: Conductor and Dielectric Loss

CPW (coplanar waveguide) exhibits lower conductor loss compared to microstrip due to its larger conductor surface area and reduced current crowding, which enhances power handling and minimizes Joule heating. Dielectric loss in CPW is typically less significant because the electromagnetic field is more confined to the air above the substrate rather than within the dielectric material, as is common in microstrip configurations. For your high-frequency signal transmission, choosing CPW can improve overall performance by reducing both conductor and dielectric losses, especially in applications sensitive to insertion loss and signal attenuation.

Choosing Between CPW and Microstrip: Key Factors

Selecting between CPW and microstrip depends on factors such as signal frequency, substrate characteristics, and integration requirements. CPW offers better confinement of the electromagnetic field, reducing radiation loss and providing easier shunt component integration, making it ideal for high-frequency circuits and monolithic microwave ICs. Your decision should consider fabrication complexity, impedance control, and the specific application to ensure optimal signal integrity and performance.

CPW (coplanar waveguide) vs microstrip Infographic

electrown.com

electrown.com