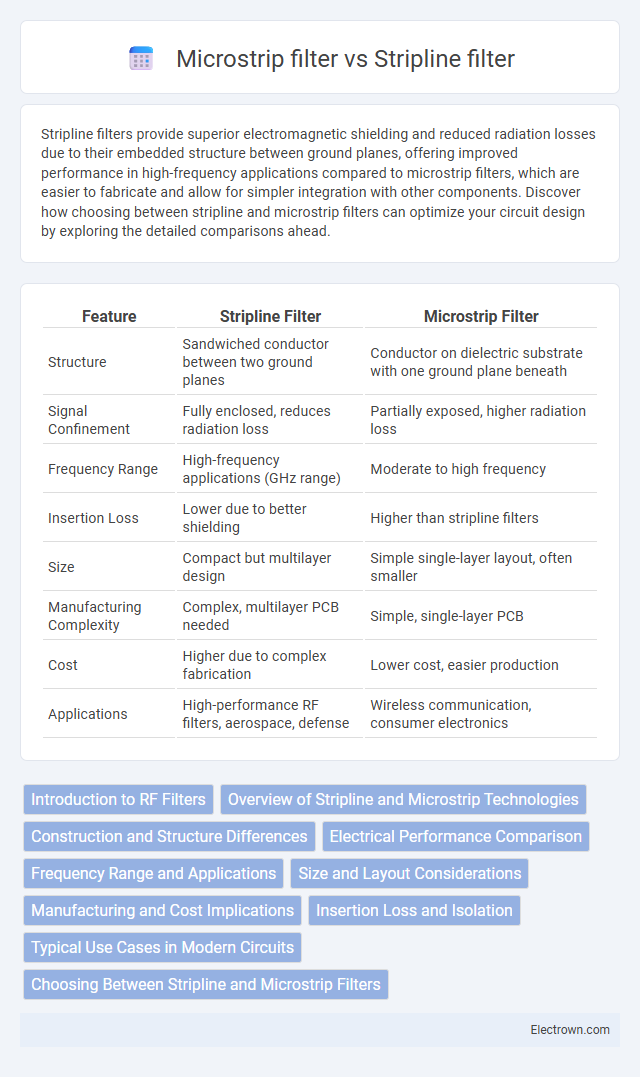

Stripline filters provide superior electromagnetic shielding and reduced radiation losses due to their embedded structure between ground planes, offering improved performance in high-frequency applications compared to microstrip filters, which are easier to fabricate and allow for simpler integration with other components. Discover how choosing between stripline and microstrip filters can optimize your circuit design by exploring the detailed comparisons ahead.

Table of Comparison

| Feature | Stripline Filter | Microstrip Filter |

|---|---|---|

| Structure | Sandwiched conductor between two ground planes | Conductor on dielectric substrate with one ground plane beneath |

| Signal Confinement | Fully enclosed, reduces radiation loss | Partially exposed, higher radiation loss |

| Frequency Range | High-frequency applications (GHz range) | Moderate to high frequency |

| Insertion Loss | Lower due to better shielding | Higher than stripline filters |

| Size | Compact but multilayer design | Simple single-layer layout, often smaller |

| Manufacturing Complexity | Complex, multilayer PCB needed | Simple, single-layer PCB |

| Cost | Higher due to complex fabrication | Lower cost, easier production |

| Applications | High-performance RF filters, aerospace, defense | Wireless communication, consumer electronics |

Introduction to RF Filters

RF filters are essential components in wireless communication systems, with stripline and microstrip filters being prominent types. Stripline filters feature a conductor sandwiched between two ground planes, offering superior shielding and reduced radiation loss, which enhances performance at higher frequencies. Microstrip filters, placed on a single dielectric substrate with one ground plane, provide ease of fabrication and integration in compact circuits but may experience higher radiation losses compared to stripline counterparts.

Overview of Stripline and Microstrip Technologies

Stripline and microstrip filters are planar transmission line technologies widely used in RF and microwave circuits for signal filtering. Stripline features a conductor sandwiched between two ground planes, offering superior electromagnetic shielding and reduced radiation loss, making it ideal for high-frequency applications above 10 GHz. Microstrip filters consist of a conductor on a dielectric substrate with a single ground plane, providing easier fabrication and integration but with higher radiation loss and sensitivity to substrate variations.

Construction and Structure Differences

Stripline filters consist of a central conductor sandwiched between two ground planes, creating a fully enclosed electromagnetic environment that minimizes radiation losses and increases shielding effectiveness. Microstrip filters use a single conductive strip separated from a ground plane by a dielectric substrate, resulting in a partially exposed structure that is easier to fabricate but more vulnerable to interference. Understanding these construction differences helps you choose the appropriate filter type for specific applications requiring controlled signal integrity or compact design.

Electrical Performance Comparison

Stripline filters offer superior electromagnetic shielding and lower radiation loss compared to microstrip filters, resulting in higher Q factors and better selectivity for high-frequency applications. Microstrip filters provide easier fabrication and integration on a single-layer PCB but often suffer from increased radiation and substrate losses, which can degrade insertion loss and out-of-band rejection performance. Your choice depends on specific requirements for signal integrity, bandwidth, and manufacturing complexity.

Frequency Range and Applications

Stripline filters operate efficiently at higher microwave frequencies typically ranging from 1 GHz to 40 GHz, making them suitable for radar systems, satellite communications, and high-frequency signal processing. Microstrip filters cover a broad frequency spectrum from hundreds of MHz up to about 20 GHz, commonly used in wireless communication, RF circuits, and cellular devices due to their ease of fabrication and integration. Both filters provide compact, planar solutions, but stripline filters offer better isolation and reduced radiation loss at ultra-high frequencies compared to microstrip variants.

Size and Layout Considerations

Stripline filters offer superior isolation and reduced radiation loss due to their enclosed structure, allowing for compact multilayer designs ideal for high-frequency applications. Microstrip filters, however, provide easier fabrication and inspection with a single-layer layout but often require more surface area because of their open, planar configuration. Size optimization in stripline filters is achieved through vertical integration, whereas microstrip filters rely heavily on lateral spacing and substrate properties to minimize footprint.

Manufacturing and Cost Implications

Stripline filters, embedded between ground planes, require multilayer PCB fabrication techniques, increasing manufacturing complexity and cost compared to microstrip filters, which are fabricated on a single-layer substrate with one ground plane. The precise alignment and additional lamination steps in stripline production contribute to higher expenses, making microstrip filters more cost-effective for mass production. However, stripline filters offer better electromagnetic shielding, which can justify the added manufacturing investment in high-performance applications.

Insertion Loss and Isolation

Stripline filters typically offer lower insertion loss compared to microstrip filters due to their enclosed structure, which reduces radiation losses and improves signal integrity. Isolation between channels is generally higher in stripline filters as the electromagnetic fields are better confined, minimizing crosstalk. Your choice between the two filters should consider these factors, especially when low insertion loss and high isolation are critical for your RF system performance.

Typical Use Cases in Modern Circuits

Stripline filters excel in applications requiring high isolation and low radiation, such as radar and communication systems operating at microwave frequencies, where precise signal integrity is crucial. Microstrip filters are commonly used in compact, low-cost wireless devices and mobile communication systems due to their ease of fabrication and integration on printed circuit boards. Your choice depends on balancing performance needs and manufacturing constraints in modern RF and microwave circuits.

Choosing Between Stripline and Microstrip Filters

Choosing between stripline and microstrip filters depends on your application's frequency range, size constraints, and interference requirements. Stripline filters offer superior isolation and better shielding, making them ideal for high-frequency, high-performance circuits, while microstrip filters provide easier fabrication and integration on single-layer PCBs suitable for moderate frequencies. Assess your design priorities such as insertion loss, dielectric losses, and PCB layering to determine which filter type optimally meets your system's performance and cost needs.

Stripline filter vs microstrip filter Infographic

electrown.com

electrown.com