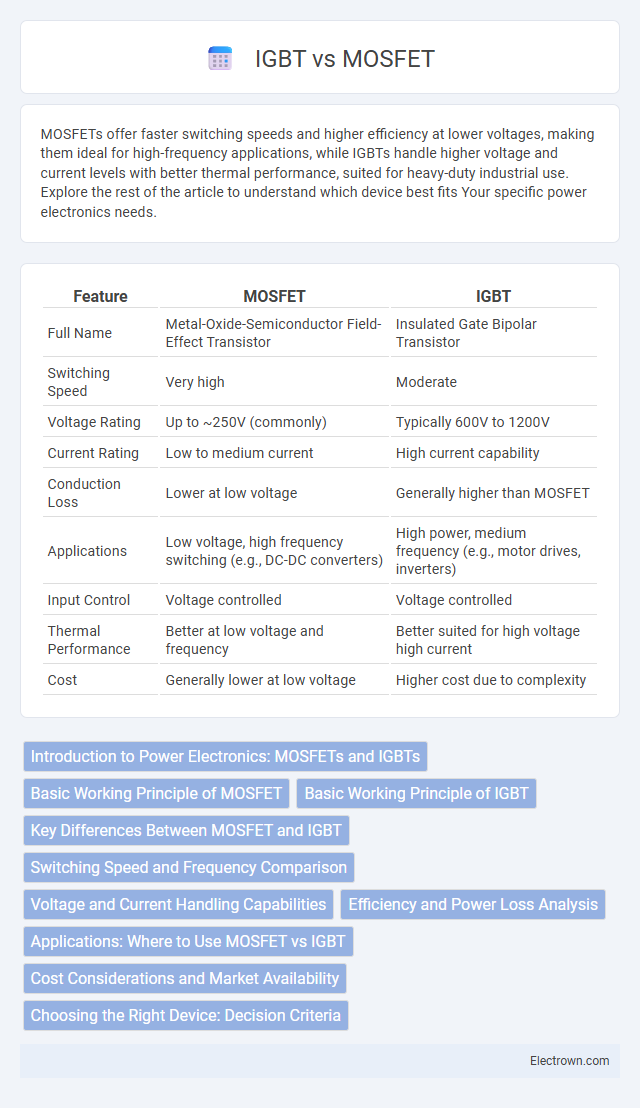

MOSFETs offer faster switching speeds and higher efficiency at lower voltages, making them ideal for high-frequency applications, while IGBTs handle higher voltage and current levels with better thermal performance, suited for heavy-duty industrial use. Explore the rest of the article to understand which device best fits Your specific power electronics needs.

Table of Comparison

| Feature | MOSFET | IGBT |

|---|---|---|

| Full Name | Metal-Oxide-Semiconductor Field-Effect Transistor | Insulated Gate Bipolar Transistor |

| Switching Speed | Very high | Moderate |

| Voltage Rating | Up to ~250V (commonly) | Typically 600V to 1200V |

| Current Rating | Low to medium current | High current capability |

| Conduction Loss | Lower at low voltage | Generally higher than MOSFET |

| Applications | Low voltage, high frequency switching (e.g., DC-DC converters) | High power, medium frequency (e.g., motor drives, inverters) |

| Input Control | Voltage controlled | Voltage controlled |

| Thermal Performance | Better at low voltage and frequency | Better suited for high voltage high current |

| Cost | Generally lower at low voltage | Higher cost due to complexity |

Introduction to Power Electronics: MOSFETs and IGBTs

MOSFETs and IGBTs serve as critical semiconductor devices in power electronics, enabling efficient switching and control of electrical power in various applications. MOSFETs offer high-speed switching and are ideal for low to medium voltage, high-frequency scenarios, while IGBTs excel in handling higher voltages and currents with robust performance in industrial motor drives and inverters. Your choice between MOSFETs and IGBTs depends on the specific power, switching frequency, and voltage requirements of your electronic system.

Basic Working Principle of MOSFET

MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) operates by controlling the voltage applied to its gate terminal, which regulates the current flow between the drain and source terminals through an electric field. When a positive voltage is applied to the gate, it creates an inversion layer that forms a conductive channel in the semiconductor material, allowing current to pass. This voltage-driven mechanism enables high-speed switching with low on-resistance, making MOSFETs ideal for low-voltage, high-frequency applications compared to IGBTs.

Basic Working Principle of IGBT

The Insulated Gate Bipolar Transistor (IGBT) operates by combining the high input impedance and fast switching of a Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) with the high current and low saturation voltage capabilities of a Bipolar Junction Transistor (BJT). When a voltage is applied to the gate, it induces an electric field that modulates the conductivity of the device's channel, allowing current to flow between the collector and emitter terminals. The IGBT's structure enables efficient switching and high power handling in industrial applications such as motor drives, inverters, and power supplies.

Key Differences Between MOSFET and IGBT

MOSFETs feature faster switching speeds and lower conduction losses, making them ideal for high-frequency applications such as power supplies and RF amplifiers. IGBTs excel in handling higher voltage and current levels with better efficiency during low to medium switching frequencies, commonly used in industrial motor drives and renewable energy systems. Your choice depends on specific requirements like switching speed, voltage rating, and efficiency for the targeted application.

Switching Speed and Frequency Comparison

MOSFETs exhibit significantly higher switching speeds, often operating in the MHz range, making them ideal for high-frequency applications such as RF amplifiers and DC-DC converters. IGBTs, while slower with switching speeds typically in the kHz range, handle higher voltages and current levels efficiently, making them suitable for medium to high-power applications like motor drives and inverters. The faster recovery time of MOSFETs results in lower switching losses compared to the relatively slower turn-off characteristics of IGBTs.

Voltage and Current Handling Capabilities

MOSFETs excel in high-speed switching and handle voltage levels typically up to 250V to 600V, making them ideal for low to medium voltage applications, while IGBTs are designed to manage higher voltages ranging from 600V to several kilovolts, suitable for high power environments. In terms of current handling, IGBTs outperform MOSFETs by efficiently managing larger currents due to their bipolar conduction mechanism, whereas MOSFETs are best for lower current tasks with fast switching demands. Your choice between MOSFET and IGBT depends heavily on the voltage and current requirements of your application to ensure optimal performance and efficiency.

Efficiency and Power Loss Analysis

MOSFETs demonstrate superior efficiency at lower voltages due to their low on-resistance and faster switching speeds, resulting in reduced conduction and switching losses compared to IGBTs. IGBTs are more efficient in high-voltage, high-current applications because they handle large power with lower conduction losses despite slower switching transitions. Power loss analysis reveals MOSFETs excel in low to medium power ranges with minimal heat dissipation, while IGBTs provide better performance in high-power industrial drives by minimizing total power losses under heavy load conditions.

Applications: Where to Use MOSFET vs IGBT

MOSFETs excel in low-voltage, high-frequency applications such as power supplies, DC-DC converters, and audio amplifiers due to their fast switching speed and high efficiency. IGBTs are better suited for high-voltage, high-current applications like motor drives, industrial inverters, and renewable energy systems, where their ability to handle large power and withstand voltage spikes is critical. Choosing between MOSFET and IGBT depends on your specific requirements for switching frequency, voltage, and current capacity to optimize performance and reliability.

Cost Considerations and Market Availability

MOSFETs generally offer lower initial costs and wider availability for low to medium voltage applications due to simpler manufacturing processes and higher production volumes. IGBTs tend to have higher upfront costs but provide cost advantages in high voltage and high current applications because of superior efficiency and thermal handling capabilities. Market availability favors MOSFETs in consumer electronics and automotive sectors, while IGBTs dominate industrial motor drives and renewable energy systems.

Choosing the Right Device: Decision Criteria

Selecting the right device between MOSFET and IGBT depends on factors such as switching speed, voltage rating, and current capacity. MOSFETs excel in low-voltage, high-frequency applications with efficient switching, while IGBTs are better suited for high-voltage, high-current scenarios with robust thermal performance. Your decision should prioritize application-specific requirements like efficiency, thermal management, and cost-effectiveness to optimize overall system performance.

MOSFET vs IGBT Infographic

electrown.com

electrown.com