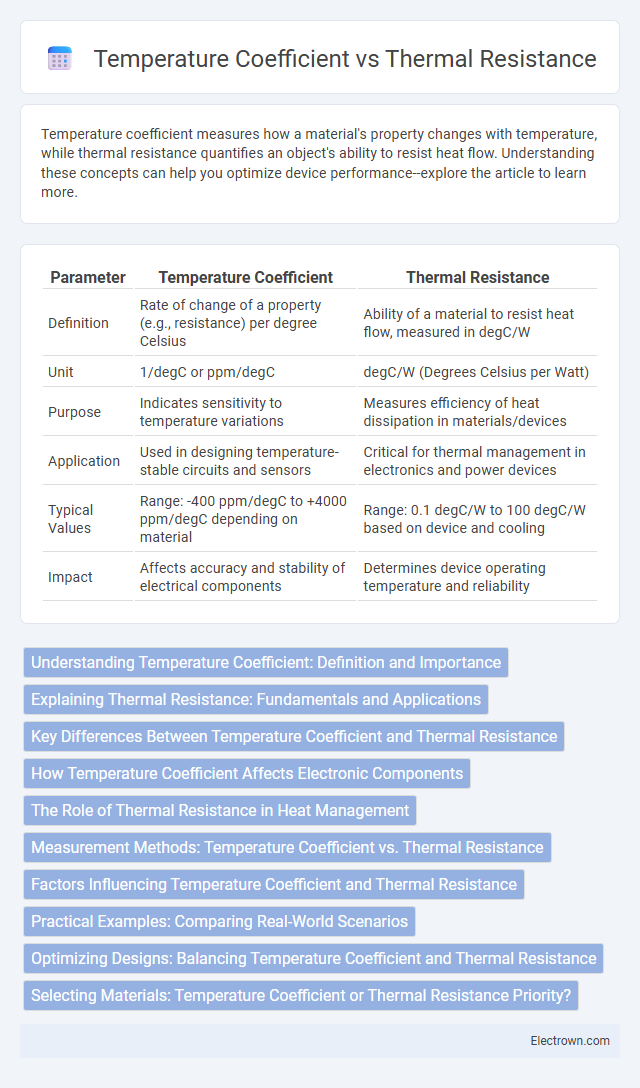

Temperature coefficient measures how a material's property changes with temperature, while thermal resistance quantifies an object's ability to resist heat flow. Understanding these concepts can help you optimize device performance--explore the article to learn more.

Table of Comparison

| Parameter | Temperature Coefficient | Thermal Resistance |

|---|---|---|

| Definition | Rate of change of a property (e.g., resistance) per degree Celsius | Ability of a material to resist heat flow, measured in degC/W |

| Unit | 1/degC or ppm/degC | degC/W (Degrees Celsius per Watt) |

| Purpose | Indicates sensitivity to temperature variations | Measures efficiency of heat dissipation in materials/devices |

| Application | Used in designing temperature-stable circuits and sensors | Critical for thermal management in electronics and power devices |

| Typical Values | Range: -400 ppm/degC to +4000 ppm/degC depending on material | Range: 0.1 degC/W to 100 degC/W based on device and cooling |

| Impact | Affects accuracy and stability of electrical components | Determines device operating temperature and reliability |

Understanding Temperature Coefficient: Definition and Importance

Temperature coefficient quantifies how a material's properties, such as resistance, change with temperature, typically expressed in parts per million per degree Celsius (ppm/degC). It is crucial for predicting device performance and ensuring reliability in varying thermal environments, influencing components like resistors and semiconductors. Understanding the temperature coefficient allows engineers to design circuits with precise thermal behavior, optimizing efficiency and preventing failure.

Explaining Thermal Resistance: Fundamentals and Applications

Thermal resistance quantifies a material's ability to resist heat flow, measured in degC/W or K/W, and is crucial for designing efficient heat dissipation systems in electronics and building insulation. It is calculated by dividing the temperature difference across a material by the heat power passing through it, directly impacting device reliability and performance. Understanding thermal resistance enables engineers to optimize thermal management, reduce overheating risks, and improve energy efficiency in various applications.

Key Differences Between Temperature Coefficient and Thermal Resistance

Temperature coefficient measures how a material's property, such as electrical resistance, changes with temperature, typically expressed in ppm/degC, while thermal resistance quantifies a material's ability to resist heat flow, measured in degC/W. Temperature coefficient is crucial for understanding performance stability in sensors and electronic components as temperature varies, whereas thermal resistance is essential for evaluating heat dissipation and preventing overheating in devices. Your choice between these parameters depends on whether you prioritize sensitivity to temperature changes or efficient thermal management.

How Temperature Coefficient Affects Electronic Components

The temperature coefficient quantifies how an electronic component's electrical properties, such as resistance or capacitance, change with temperature fluctuations, directly influencing performance stability. A high temperature coefficient indicates significant variation in device parameters, potentially causing drift or failure under thermal stress. In contrast, thermal resistance measures a component's ability to dissipate heat, affecting how quickly it reaches the temperatures that activate these temperature coefficient-related changes.

The Role of Thermal Resistance in Heat Management

Thermal resistance quantifies a material's ability to resist heat flow, directly impacting the efficiency of heat dissipation in electronic devices. A lower thermal resistance indicates better heat conduction, which helps maintain optimal operating temperatures and prevents overheating. Managing thermal resistance is crucial for enhancing device reliability and prolonging lifespan by minimizing thermal stress.

Measurement Methods: Temperature Coefficient vs. Thermal Resistance

Measurement methods for temperature coefficient typically involve precise resistance or voltage monitoring over a controlled temperature range using devices such as temperature chambers and precision multimeters. Thermal resistance measurement requires evaluating heat flow and temperature gradients, often employing thermocouples, infrared thermography, or thermal transient analysis to assess how effectively a material or component dissipates heat. Both methods rely on specialized equipment and standardized procedures to ensure accurate and repeatable characterization of thermal properties.

Factors Influencing Temperature Coefficient and Thermal Resistance

Material composition and device geometry significantly influence the temperature coefficient, determining how electrical parameters vary with temperature changes. Thermal resistance depends largely on the heat dissipation capabilities of the material and packaging design, affecting the efficiency of heat transfer from the device to the environment. Both factors are crucial in optimizing device performance under varying thermal conditions, with substrate material, interface quality, and ambient temperature playing key roles.

Practical Examples: Comparing Real-World Scenarios

Temperature coefficient quantifies how a material's property, such as resistance, changes with temperature, while thermal resistance measures a component's ability to resist heat flow. In practical electronics cooling, a thermistor's resistance varies significantly with temperature due to its temperature coefficient, affecting circuit performance. Conversely, heat sinks rely on low thermal resistance to dissipate heat efficiently, ensuring device stability under varying thermal conditions.

Optimizing Designs: Balancing Temperature Coefficient and Thermal Resistance

Optimizing designs requires balancing the temperature coefficient and thermal resistance to ensure stable device performance across varying temperatures. Lower temperature coefficients improve accuracy by minimizing property changes with temperature, while reduced thermal resistance enhances heat dissipation, preventing overheating. You can achieve efficient thermal management and reliable operation by carefully selecting materials and design parameters that address both factors.

Selecting Materials: Temperature Coefficient or Thermal Resistance Priority?

When selecting materials for thermal management, prioritizing temperature coefficient or thermal resistance depends on your application's specific demands. Temperature coefficient measures how a material's electrical resistance changes with temperature, critical for precision sensors and circuits requiring stability. Thermal resistance quantifies a material's ability to resist heat flow, essential for heat dissipation and maintaining device reliability under varying thermal loads.

temperature coefficient vs thermal resistance Infographic

electrown.com

electrown.com