Chopper amplifiers excel in low-frequency applications by minimizing offset voltage and flicker noise through periodic switching, making them ideal for precise DC measurements. Instrumentation amplifiers offer high input impedance, excellent common-mode rejection, and gain accuracy, which are essential for amplifying small differential signals in noisy environments; explore the rest of the article to understand which amplifier suits your specific application needs.

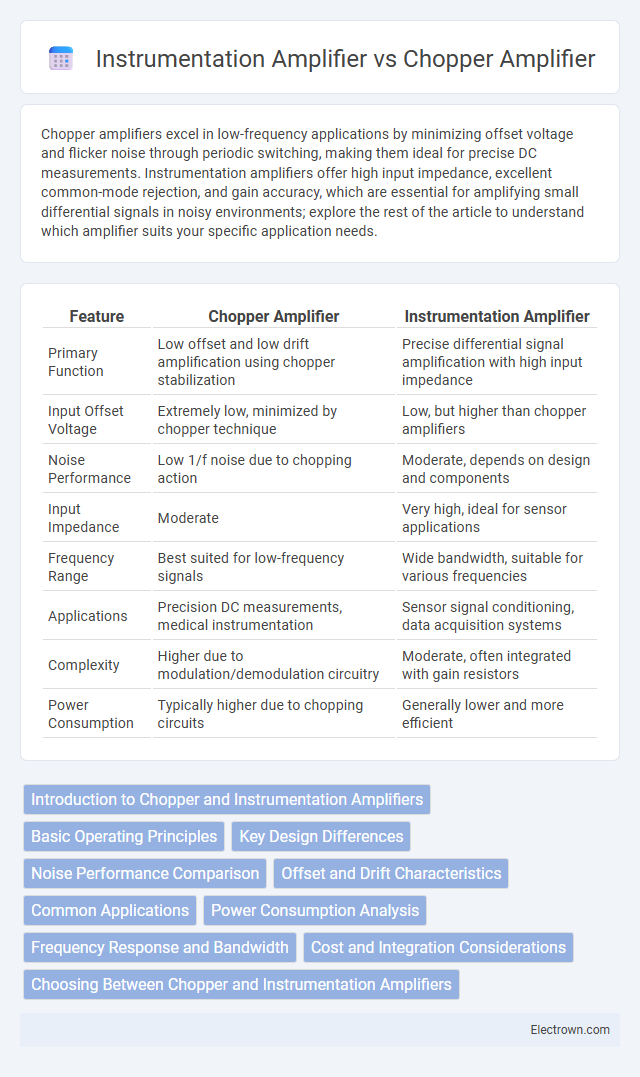

Table of Comparison

| Feature | Chopper Amplifier | Instrumentation Amplifier |

|---|---|---|

| Primary Function | Low offset and low drift amplification using chopper stabilization | Precise differential signal amplification with high input impedance |

| Input Offset Voltage | Extremely low, minimized by chopper technique | Low, but higher than chopper amplifiers |

| Noise Performance | Low 1/f noise due to chopping action | Moderate, depends on design and components |

| Input Impedance | Moderate | Very high, ideal for sensor applications |

| Frequency Range | Best suited for low-frequency signals | Wide bandwidth, suitable for various frequencies |

| Applications | Precision DC measurements, medical instrumentation | Sensor signal conditioning, data acquisition systems |

| Complexity | Higher due to modulation/demodulation circuitry | Moderate, often integrated with gain resistors |

| Power Consumption | Typically higher due to chopping circuits | Generally lower and more efficient |

Introduction to Chopper and Instrumentation Amplifiers

Chopper amplifiers use a chopping technique to modulate low-frequency input signals, effectively reducing offset voltage and low-frequency noise, making them ideal for precision DC measurements. Instrumentation amplifiers feature high input impedance, excellent common-mode rejection ratio (CMRR), and stable gain, optimizing them for accurate signal amplification in noisy environments. Your choice depends on the need for ultra-low offset noise (favoring chopper amplifiers) or robust differential signal conditioning (favoring instrumentation amplifiers).

Basic Operating Principles

Chopper amplifiers utilize a modulation-demodulation technique to reduce low-frequency noise and offset by periodically switching the input signal, enabling precise amplification of DC and low-frequency signals. Instrumentation amplifiers employ a differential input stage combined with high input impedance and precise gain setting resistors to provide accurate and stable amplification of differential signals while rejecting common-mode noise. Both amplifier types optimize signal integrity for sensitive measurements but differ fundamentally in noise handling and input conditioning methodologies.

Key Design Differences

Chopper amplifiers utilize modulation techniques to reduce offset and low-frequency noise, making them ideal for precise DC measurements, while instrumentation amplifiers employ a three-op-amp configuration optimized for high input impedance and accurate differential signal amplification. Chopper amplifiers typically feature auto-zeroing, enhancing stability in low-frequency applications, whereas instrumentation amplifiers prioritize input common-mode rejection ratio (CMRR) and gain precision through matched resistors. Your choice depends on the required noise performance and signal fidelity for applications such as sensor signal conditioning or biomedical instrumentation.

Noise Performance Comparison

Chopper amplifiers excel in low-frequency noise performance by using modulation techniques to minimize offset and 1/f noise, making them ideal for precision DC measurements. Instrumentation amplifiers typically offer high input impedance and good common-mode rejection but may exhibit higher noise levels compared to chopper amplifiers in ultra-low noise environments. For applications demanding sub-microvolt offsets and noise floors, chopper amplifiers provide superior noise performance over traditional instrumentation amplifiers.

Offset and Drift Characteristics

Chopper amplifiers offer extremely low offset voltage and near-zero drift due to their internal auto-zeroing technique, making them ideal for precision measurements in low-frequency applications. Instrumentation amplifiers typically have higher input offset and drift but excel in high common-mode rejection and ease of gain adjustment. Your choice depends on whether minimal offset and drift or robustness against noise and common-mode voltages is more critical for your application.

Common Applications

Chopper amplifiers are commonly used in low-frequency precision applications such as medical instrumentation, strain gauge sensors, and thermocouple signal conditioning due to their ultra-low offset and low noise performance. Instrumentation amplifiers are preferred in data acquisition systems, industrial process controls, and bioelectric measurements where high input impedance, accurate gain, and excellent common-mode rejection are critical. Both amplifier types excel in enhancing small differential signals but cater to distinct precision amplification needs in sensor interface and measurement systems.

Power Consumption Analysis

Chopper amplifiers typically exhibit lower power consumption compared to traditional instrumentation amplifiers due to their ability to minimize offset voltage and low-frequency noise without requiring extensive filtering or amplification stages. Instrumentation amplifiers, designed for high precision and stability, often consume more power because of their complex multi-stage architecture and higher quiescent currents. Thus, in applications where minimizing power is critical, chopper amplifiers offer a more efficient solution, especially in battery-powered and portable devices.

Frequency Response and Bandwidth

Chopper amplifiers provide excellent low-frequency performance with minimal offset and drift, resulting in superior accuracy in DC to low-frequency applications but typically have limited bandwidth, often under 100 kHz. Instrumentation amplifiers offer wider bandwidths, typically ranging from hundreds of kilohertz to several megahertz, making them suitable for higher frequency signal amplification with moderate noise and offset characteristics. Frequency response in chopper amplifiers is optimized for stability and precision at low frequencies, while instrumentation amplifiers balance gain accuracy and bandwidth for broader frequency applications.

Cost and Integration Considerations

Chopper amplifiers generally offer lower noise and better DC precision at a higher cost compared to instrumentation amplifiers, which are typically more cost-effective for standard applications. Instrumentation amplifiers provide easier integration with fewer external components, making them suitable for straightforward sensor interfacing. Your choice depends on balancing budget constraints with the required measurement accuracy and integration complexity.

Choosing Between Chopper and Instrumentation Amplifiers

Chopper amplifiers excel in ultra-low offset voltage and low noise applications, making them ideal for precise DC measurements in sensor signal conditioning and medical devices. Instrumentation amplifiers provide high input impedance, excellent common-mode rejection ratio (CMRR), and stable gain, which suits applications requiring accurate differential signal amplification in industrial automation and data acquisition systems. The choice depends on the specific requirements for offset stability, noise performance, bandwidth, and input characteristics in the target application.

Chopper amplifier vs instrumentation amplifier Infographic

electrown.com

electrown.com