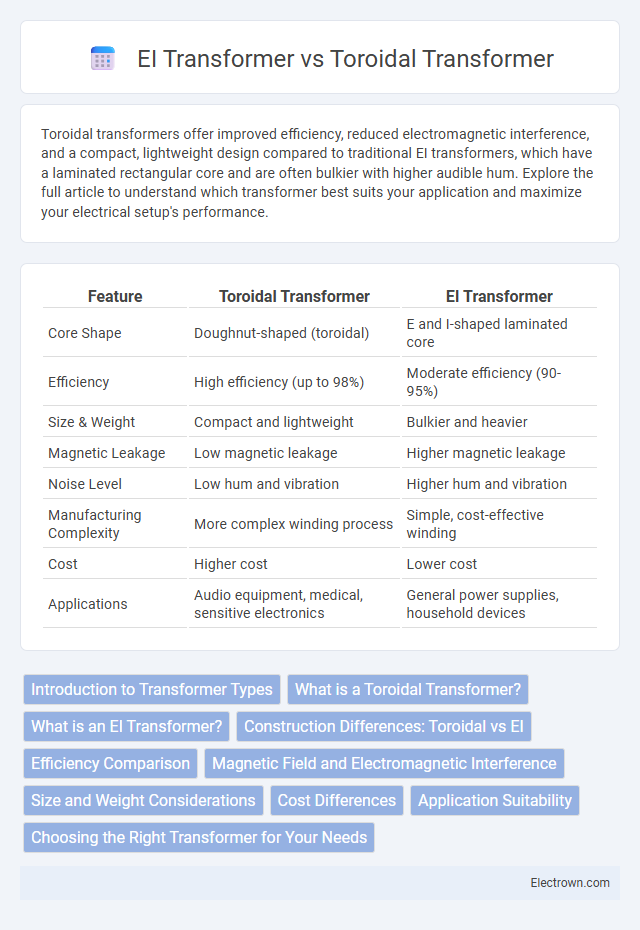

Toroidal transformers offer improved efficiency, reduced electromagnetic interference, and a compact, lightweight design compared to traditional EI transformers, which have a laminated rectangular core and are often bulkier with higher audible hum. Explore the full article to understand which transformer best suits your application and maximize your electrical setup's performance.

Table of Comparison

| Feature | Toroidal Transformer | EI Transformer |

|---|---|---|

| Core Shape | Doughnut-shaped (toroidal) | E and I-shaped laminated core |

| Efficiency | High efficiency (up to 98%) | Moderate efficiency (90-95%) |

| Size & Weight | Compact and lightweight | Bulkier and heavier |

| Magnetic Leakage | Low magnetic leakage | Higher magnetic leakage |

| Noise Level | Low hum and vibration | Higher hum and vibration |

| Manufacturing Complexity | More complex winding process | Simple, cost-effective winding |

| Cost | Higher cost | Lower cost |

| Applications | Audio equipment, medical, sensitive electronics | General power supplies, household devices |

Introduction to Transformer Types

Toroidal transformers feature a doughnut-shaped core that provides high efficiency, low electromagnetic interference, and compact design, making them ideal for sensitive electronic applications. EI transformers utilize an E-shaped laminated core combined with an I-shaped piece, offering cost-effectiveness and robustness for general power supply needs. Choosing the right transformer type depends on your specific requirements for size, noise level, efficiency, and application environment.

What is a Toroidal Transformer?

A toroidal transformer features a donut-shaped core made from a continuous strip of silicon steel, enhancing magnetic efficiency and reducing electromagnetic interference compared to EI transformers. Its compact, lightweight design results in lower audible noise and improved energy performance, making it ideal for audio equipment and medical devices. Choosing a toroidal transformer can elevate your system's reliability and minimize stray magnetic fields.

What is an EI Transformer?

An EI transformer features a laminated core shaped like the letters "E" and "I," designed to reduce eddy current losses and improve efficiency in electrical devices. This type of transformer is commonly used in low-frequency applications such as power supplies and audio equipment due to its robust construction and cost-effectiveness. Understanding your power requirements will help determine if an EI transformer suits your needs better than a toroidal alternative.

Construction Differences: Toroidal vs EI

Toroidal transformers feature a doughnut-shaped core made from a continuous strip of silicon steel, which reduces core losses and electromagnetic interference due to their closed-loop design. In contrast, EI transformers use a laminated E-shaped core stacked with I-shaped laminations, causing higher magnetic flux leakage and acoustic noise from mechanical vibrations. The compact and symmetrical winding of toroidal transformers offers improved efficiency and reduced size compared to the bulkier construction of EI transformers.

Efficiency Comparison

Toroidal transformers typically exhibit higher efficiency rates, often reaching up to 95-98% due to their minimal core losses and superior magnetic flux distribution. EI transformers generally have lower efficiency, around 85-90%, caused by increased core losses and leakage flux due to their laminated E and I core design. The compact design and reduced winding resistance of toroidal transformers contribute significantly to their better energy efficiency compared to EI transformers.

Magnetic Field and Electromagnetic Interference

Toroidal transformers have a doughnut-shaped core that confines the magnetic field within the core, significantly reducing electromagnetic interference (EMI) compared to EI transformers, which have an E-shaped and I-shaped laminated core that allows more magnetic flux leakage. This containment of the magnetic field in toroidal transformers minimizes noise and stray electromagnetic radiation, making them ideal for sensitive electronic equipment and audio applications. Your choice of transformer impacts EMI levels and overall electromagnetic compatibility, with toroidal designs offering superior performance in environments requiring low interference.

Size and Weight Considerations

Toroidal transformers offer a compact, lightweight design due to their doughnut-shaped core, reducing magnetic flux leakage and enhancing efficiency compared to traditional EI transformers. EI transformers tend to be bulkier and heavier because of their laminated steel core with E and I-shaped parts, resulting in larger size for equivalent power ratings. The reduced size and weight of toroidal transformers make them ideal for applications with space constraints or where minimizing overall weight is critical.

Cost Differences

Toroidal transformers generally cost more than EI transformers due to their complex manufacturing process and superior efficiency. EI transformers are more economical to produce, making them a preferred choice in budget-sensitive applications. The price gap can be significant, with toroidal transformers often costing up to 2-3 times more than equivalent EI transformers.

Application Suitability

Toroidal transformers offer compact size and low electromagnetic interference, making them ideal for audio equipment, medical devices, and precision instrumentation where space and noise reduction are crucial. EI transformers provide robustness and cost-effectiveness, suitable for general power supplies, industrial machinery, and applications requiring higher power handling and durability. Selecting between toroidal and EI transformers depends on specific requirements such as size constraints, efficiency, noise sensitivity, and power capacity.

Choosing the Right Transformer for Your Needs

Choosing the right transformer depends on your specific application requirements, with toroidal transformers offering advantages such as higher efficiency, lower electromagnetic interference, and compact, lightweight design. EI transformers, while bulkier and heavier, provide cost-effective solutions with easier mounting and straightforward manufacturing processes suitable for standard electrical devices. Evaluating factors like size constraints, noise sensitivity, efficiency needs, and budget will help you determine the ideal transformer type for your project.

toroidal vs EI transformer Infographic

electrown.com

electrown.com