PWM dimming controls LED brightness by rapidly switching the LED on and off, adjusting the duty cycle to create varying light intensity without affecting color temperature. Understanding the differences and benefits of PWM vs analog dimming can help you choose the optimal method for your LED lighting needs--explore the rest of the article to learn more.

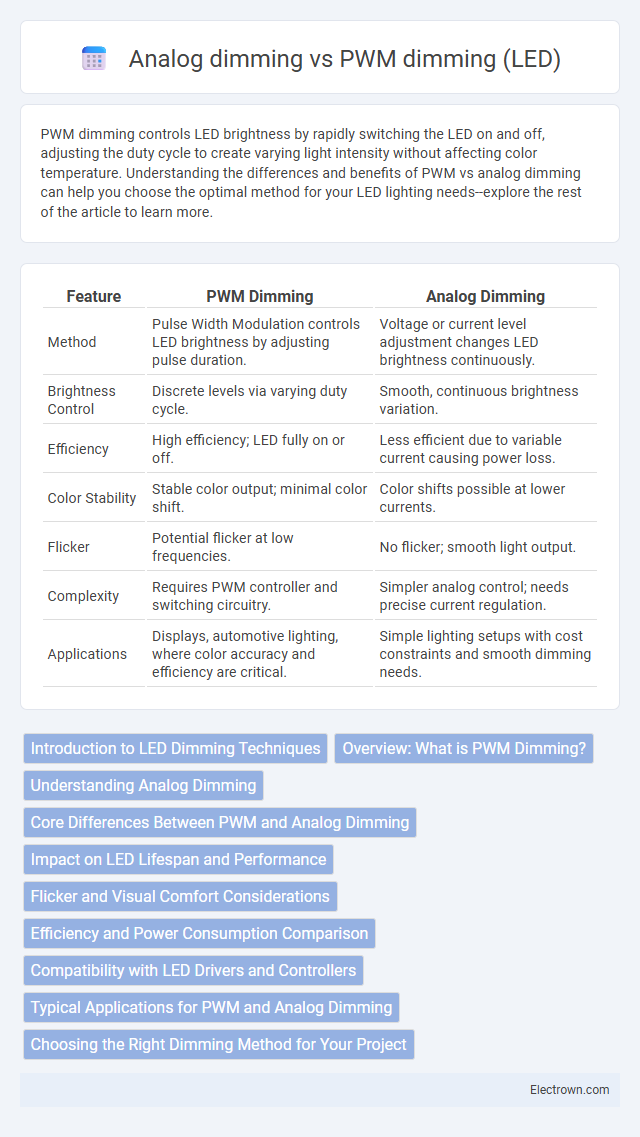

Table of Comparison

| Feature | PWM Dimming | Analog Dimming |

|---|---|---|

| Method | Pulse Width Modulation controls LED brightness by adjusting pulse duration. | Voltage or current level adjustment changes LED brightness continuously. |

| Brightness Control | Discrete levels via varying duty cycle. | Smooth, continuous brightness variation. |

| Efficiency | High efficiency; LED fully on or off. | Less efficient due to variable current causing power loss. |

| Color Stability | Stable color output; minimal color shift. | Color shifts possible at lower currents. |

| Flicker | Potential flicker at low frequencies. | No flicker; smooth light output. |

| Complexity | Requires PWM controller and switching circuitry. | Simpler analog control; needs precise current regulation. |

| Applications | Displays, automotive lighting, where color accuracy and efficiency are critical. | Simple lighting setups with cost constraints and smooth dimming needs. |

Introduction to LED Dimming Techniques

LED dimming techniques primarily include Pulse Width Modulation (PWM) dimming and Analog dimming, each offering distinct control methods for adjusting brightness. PWM dimming regulates light intensity by switching the LED on and off at high frequencies, maintaining color consistency and efficiency, while Analog dimming reduces the current supplied to the LED, which can affect color stability and efficiency. Understanding these methods helps you choose the best dimming solution for your LED lighting applications, optimizing performance and user experience.

Overview: What is PWM Dimming?

PWM dimming controls LED brightness by rapidly switching the LED on and off at a fixed frequency, varying the duty cycle to adjust perceived luminosity without changing the LED current. This method maintains consistent color temperature and efficiency across dimming levels, making it ideal for precise brightness control in LED lighting applications. Compared to analog dimming, which reduces current to lower brightness, PWM avoids color shifts and thermal issues associated with current variation.

Understanding Analog Dimming

Analog dimming controls LED brightness by adjusting the current supplied to the LED, resulting in a smooth and continuous range of light output. This method avoids flicker and electromagnetic interference associated with PWM dimming by maintaining a steady current rather than rapid switching. Understanding analog dimming involves recognizing its advantages in applications requiring stable and flicker-free illumination, such as in photography or visual arts lighting.

Core Differences Between PWM and Analog Dimming

PWM dimming controls LED brightness by rapidly switching the LED on and off at a specific frequency, adjusting duty cycle to vary light intensity without altering color temperature. Analog dimming reduces LED brightness by decreasing the current supplied to the LED, which can affect both light intensity and color output. Your choice between PWM and analog dimming impacts efficiency, flicker risk, and color stability in LED lighting applications.

Impact on LED Lifespan and Performance

PWM dimming maintains LED lifespan by reducing current pulses without altering voltage, which prevents thermal stress and color shifting common in analog dimming. Analog dimming, achieved by lowering the continuous current, risks overheating and shortens LED lifespan due to constant voltage drops and degraded phosphor efficiency. Performance-wise, PWM offers precise dimming levels and consistent color quality, while analog dimming may cause flickering and color instability at low brightness.

Flicker and Visual Comfort Considerations

PWM dimming controls LED brightness by rapidly switching the light on and off, which can cause flicker detectable by sensitive individuals, potentially leading to eye strain and discomfort. Analog dimming adjusts LED current continuously, providing smoother light output with minimal flicker, enhancing visual comfort. Your choice between these methods impacts flicker sensitivity and overall lighting quality in your environment.

Efficiency and Power Consumption Comparison

PWM dimming offers higher efficiency by rapidly switching LEDs on and off, minimizing power loss during operation and maintaining consistent color quality. Analog dimming reduces current continuously but can lead to increased power consumption and heat generation due to lower operating voltage efficiency. Your choice impacts overall energy savings, with PWM generally providing better power consumption performance for LED lighting applications.

Compatibility with LED Drivers and Controllers

PWM dimming offers superior compatibility with most LED drivers and controllers due to its digital switching method, allowing precise brightness control without altering voltage levels. Analog dimming can cause compatibility issues since it adjusts the LED current or voltage directly, which may result in inconsistent brightness and reduced efficiency with certain drivers. Your choice of dimming method affects not only LED performance but also the longevity and reliability of the driver-controller system.

Typical Applications for PWM and Analog Dimming

PWM dimming is commonly used in applications requiring precise brightness control and color consistency, such as LED displays, automotive lighting, and stage lighting, where flicker-free operation and energy efficiency are critical. Analog dimming is often preferred in simpler, cost-sensitive applications like residential lighting and backlighting in consumer electronics, where smooth dimming without complex circuitry suffices. Your choice between PWM and analog dimming depends on the balance between performance needs and system complexity.

Choosing the Right Dimming Method for Your Project

PWM dimming offers precise control over LED brightness by rapidly switching the light on and off, resulting in consistent color temperature and high efficiency, making it ideal for applications requiring fine-tuned light intensity. Analog dimming adjusts the LED current continuously, often leading to color shifts and reduced efficiency but provides a simpler implementation for low-cost projects. Your choice between PWM and analog dimming should consider factors like desired color stability, system complexity, cost constraints, and the specific lighting environment.

PWM dimming vs Analog dimming (LED) Infographic

electrown.com

electrown.com