Power modules integrate multiple power components into a single, compact unit, offering enhanced efficiency, reduced design complexity, and improved thermal management compared to discrete components, which require individual assembly and larger PCB space. Explore this article to understand how choosing between power modules and discrete components can impact your electronic system's performance and reliability.

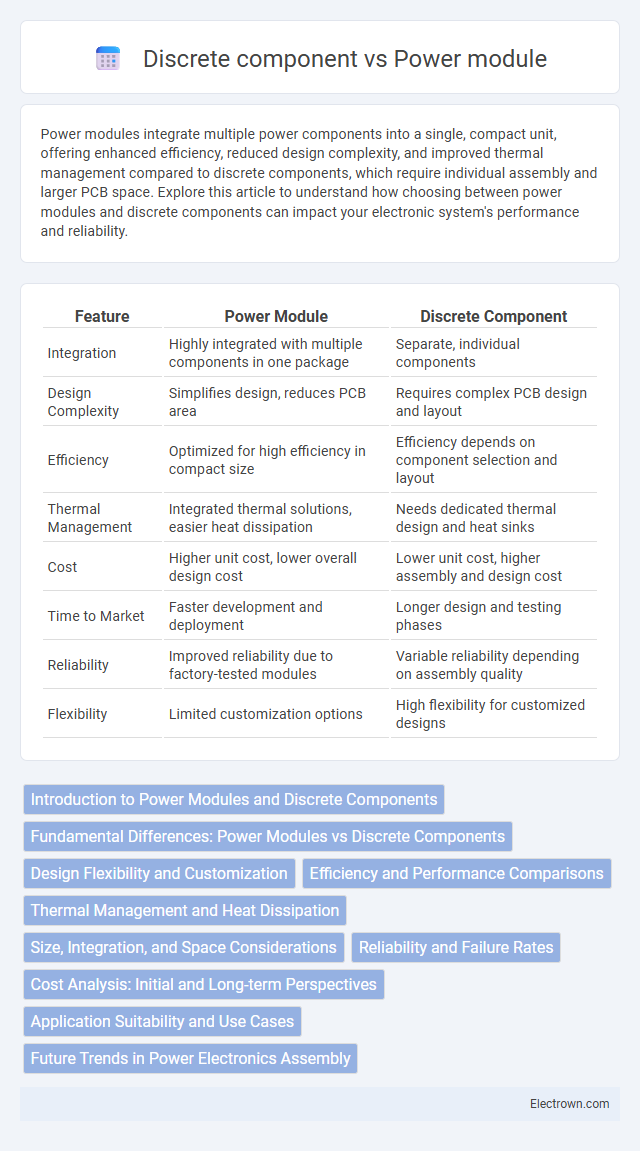

Table of Comparison

| Feature | Power Module | Discrete Component |

|---|---|---|

| Integration | Highly integrated with multiple components in one package | Separate, individual components |

| Design Complexity | Simplifies design, reduces PCB area | Requires complex PCB design and layout |

| Efficiency | Optimized for high efficiency in compact size | Efficiency depends on component selection and layout |

| Thermal Management | Integrated thermal solutions, easier heat dissipation | Needs dedicated thermal design and heat sinks |

| Cost | Higher unit cost, lower overall design cost | Lower unit cost, higher assembly and design cost |

| Time to Market | Faster development and deployment | Longer design and testing phases |

| Reliability | Improved reliability due to factory-tested modules | Variable reliability depending on assembly quality |

| Flexibility | Limited customization options | High flexibility for customized designs |

Introduction to Power Modules and Discrete Components

Power modules integrate multiple power semiconductor devices and passive components into a single package, offering compact design and improved thermal management. Discrete components consist of individual electronic parts such as transistors, diodes, and resistors, allowing flexible circuit design but requiring more board space and complex assembly. Your choice between power modules and discrete components depends on space constraints, efficiency requirements, and system complexity.

Fundamental Differences: Power Modules vs Discrete Components

Power modules integrate multiple power components such as transistors, diodes, and resistors into a single packaged unit, offering improved thermal management and simplified design compared to discrete components. Discrete components, by contrast, are individual electronic parts that provide greater flexibility for custom circuit configurations but require more complex assembly and precise layout for optimal performance. Your choice between power modules and discrete components depends on factors like space constraints, efficiency requirements, and ease of implementation in power electronics.

Design Flexibility and Customization

Power modules offer limited design flexibility due to their predefined configurations, while discrete components provide extensive customization options tailored to specific circuit requirements. Designers can optimize performance, thermal management, and footprint more precisely with discrete components by selecting individual parts based on electrical and mechanical characteristics. This granular control enables innovative solutions in complex power electronics applications where adaptability is critical.

Efficiency and Performance Comparisons

Power modules offer higher efficiency through integrated design that minimizes parasitic losses and optimizes thermal management compared to discrete components. Discrete components provide flexibility but often result in lower performance due to increased wiring inductance and less compact layouts, which can cause higher power loss and reduced switching speeds. Advanced power modules deliver improved power density and enhanced reliability, making them preferable in high-performance, energy-sensitive applications.

Thermal Management and Heat Dissipation

Power modules offer superior thermal management compared to discrete components by integrating multiple elements in a compact package designed for efficient heat dissipation through built-in heat sinks and thermal interface materials. Discrete components require careful individual placement and additional cooling solutions, often leading to higher thermal resistance and uneven heat distribution. Optimizing your design with power modules can significantly enhance heat dissipation performance and reliability in high-power applications.

Size, Integration, and Space Considerations

Power modules offer a compact and highly integrated solution, combining multiple discrete components into a single package that reduces overall PCB space and simplifies thermal management. Discrete components, while offering flexibility in layout and customization, typically occupy more board area and require careful spacing to avoid interference and ensure reliability. Optimizing your design with power modules can significantly minimize size constraints and improve system efficiency in space-limited applications.

Reliability and Failure Rates

Power modules exhibit higher reliability and lower failure rates compared to discrete components due to integrated design and optimized thermal management. The encapsulated construction of power modules reduces vulnerability to environmental stressors, enhancing operational stability. Discrete components, while flexible, are more prone to thermal and mechanical failures because of individual packaging and variable interconnections.

Cost Analysis: Initial and Long-term Perspectives

Power modules typically have higher initial costs due to integrated design and packaging complexities, while discrete components offer lower upfront expenses by allowing selective purchasing. Over the long term, power modules often reduce total cost of ownership through improved efficiency, reduced assembly time, and enhanced reliability, minimizing maintenance and replacement expenses. Discrete components may incur higher lifecycle costs from increased labor, potential failures, and less optimal thermal management impacting system longevity.

Application Suitability and Use Cases

Power modules offer compact, integrated solutions ideal for high-density applications like data centers, electric vehicles, and renewable energy systems where efficiency and thermal management are crucial. Discrete components provide greater flexibility and customization, making them suitable for low-power, cost-sensitive designs or specialized circuits requiring tailored configurations. Your choice depends on application requirements, balancing integration benefits against design complexity and scalability.

Future Trends in Power Electronics Assembly

Future trends in power electronics assembly emphasize the shift from discrete components to integrated power modules due to improved efficiency, reduced size, and enhanced thermal management. Power modules incorporate advanced materials like silicon carbide (SiC) and gallium nitride (GaN), enabling higher switching frequencies and better power density. Your electronics designs will benefit from these innovations by achieving greater reliability and performance in compact form factors.

Power module vs Discrete component Infographic

electrown.com

electrown.com