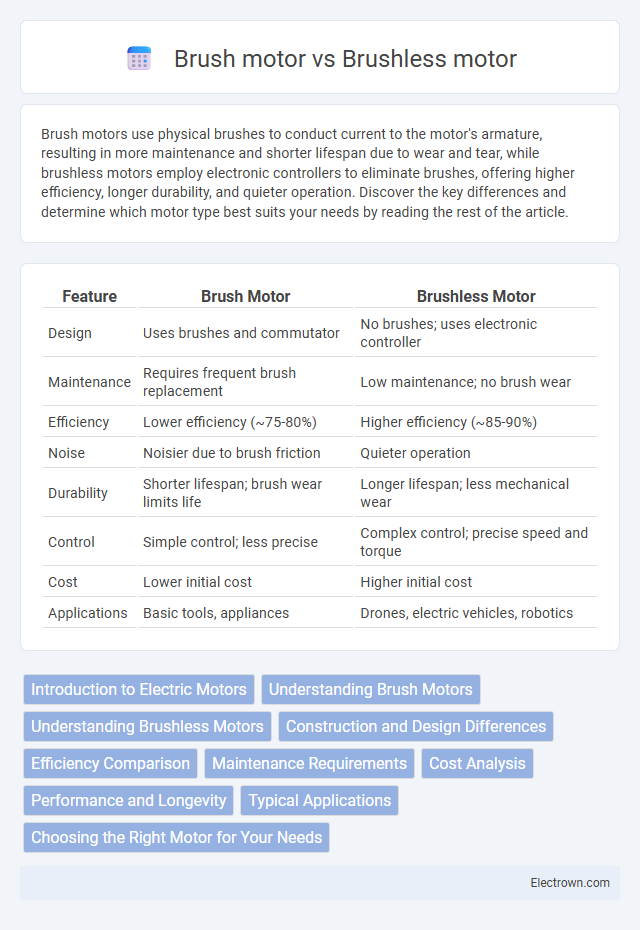

Brush motors use physical brushes to conduct current to the motor's armature, resulting in more maintenance and shorter lifespan due to wear and tear, while brushless motors employ electronic controllers to eliminate brushes, offering higher efficiency, longer durability, and quieter operation. Discover the key differences and determine which motor type best suits your needs by reading the rest of the article.

Table of Comparison

| Feature | Brush Motor | Brushless Motor |

|---|---|---|

| Design | Uses brushes and commutator | No brushes; uses electronic controller |

| Maintenance | Requires frequent brush replacement | Low maintenance; no brush wear |

| Efficiency | Lower efficiency (~75-80%) | Higher efficiency (~85-90%) |

| Noise | Noisier due to brush friction | Quieter operation |

| Durability | Shorter lifespan; brush wear limits life | Longer lifespan; less mechanical wear |

| Control | Simple control; less precise | Complex control; precise speed and torque |

| Cost | Lower initial cost | Higher initial cost |

| Applications | Basic tools, appliances | Drones, electric vehicles, robotics |

Introduction to Electric Motors

Electric motors convert electrical energy into mechanical motion, with brush motors utilizing carbon brushes to transfer current to the rotor, resulting in friction and wear. Brushless motors eliminate brushes by electronically controlling the rotor position, enhancing efficiency and longevity. Brushless motors offer higher torque-to-weight ratios, reduced maintenance, and improved reliability compared to traditional brushed motors in various applications.

Understanding Brush Motors

Brush motors use carbon brushes to transfer electrical current to the motor's rotating armature, which creates friction and wear over time. This design makes brush motors simpler and more cost-effective but requires regular maintenance and results in shorter lifespan compared to brushless motors. Understanding your application's need for durability and efficiency helps determine if a brush motor is the right choice.

Understanding Brushless Motors

Brushless motors use electronic controllers to switch current in the motor windings, eliminating the need for brushes and reducing mechanical wear and maintenance. This design offers higher efficiency, longer lifespan, and better performance at various speeds compared to traditional brushed motors. Commonly found in applications like drones, electric vehicles, and industrial machinery, brushless motors provide quieter operation and more precise control.

Construction and Design Differences

Brush motors feature a simple construction with brushes and a commutator that mechanically switch current to the motor windings, leading to increased wear and maintenance. Brushless motors use electronic controllers to manage current flow, eliminating brushes and commutators, which results in higher efficiency and longevity. Your choice between brush and brushless motors depends on the need for durability, noise level, and performance in specific applications.

Efficiency Comparison

Brushless motors offer higher efficiency than brush motors due to reduced friction and electrical losses, resulting in longer operational life and lower maintenance requirements. Brush motors suffer energy losses through brush friction and voltage drops, which decrease overall efficiency and generate more heat. Choosing a brushless motor can significantly improve your device's performance and energy consumption.

Maintenance Requirements

Brush motors require regular maintenance due to brush wear and commutator cleaning, which can lead to frequent replacements and downtime. Brushless motors eliminate these components, significantly reducing maintenance needs and improving longevity. Your choice depends on whether lower upkeep or initial cost is more important for your application.

Cost Analysis

Brush motors generally have lower upfront costs due to simpler design and manufacturing processes, making them ideal for budget-conscious applications. Brushless motors offer higher efficiency and longer lifespan, which reduces maintenance costs and total cost of ownership over time despite their higher initial price. When evaluating cost analysis, the choice depends on balancing initial investment against long-term savings in repair and energy consumption.

Performance and Longevity

Brushless motors deliver higher performance with increased efficiency and reduced heat generation compared to brush motors, resulting in smoother operation and greater power output. The absence of brushes eliminates mechanical wear, significantly extending the lifespan and minimizing maintenance requirements for brushless motors. Brush motors experience slower performance degradation due to brush friction and require periodic replacement, which limits their overall longevity and reliability.

Typical Applications

Brush motors are commonly used in household appliances, power tools, and automotive starters due to their simplicity and cost-effectiveness. Brushless motors excel in applications requiring high efficiency and durability, such as drones, electric vehicles, and computer cooling systems. Your choice depends on the specific demands for maintenance, noise level, and performance in your application.

Choosing the Right Motor for Your Needs

Brush motors offer simplicity and cost-effectiveness, making them suitable for applications requiring straightforward design and moderate performance. Brushless motors deliver higher efficiency, longer lifespan, and superior precision, ideal for high-demand uses like drones, electric vehicles, and robotics. Evaluating factors such as torque requirements, maintenance capacity, and budget helps you choose the right motor for your needs.

Brush motor vs Brushless motor Infographic

electrown.com

electrown.com