E-fuses provide faster and more precise circuit protection by electronically detecting overcurrent conditions, unlike conventional fuses that rely on a physical wire melting process. Explore the full article to understand how choosing the right fuse can impact the safety and efficiency of your electrical systems.

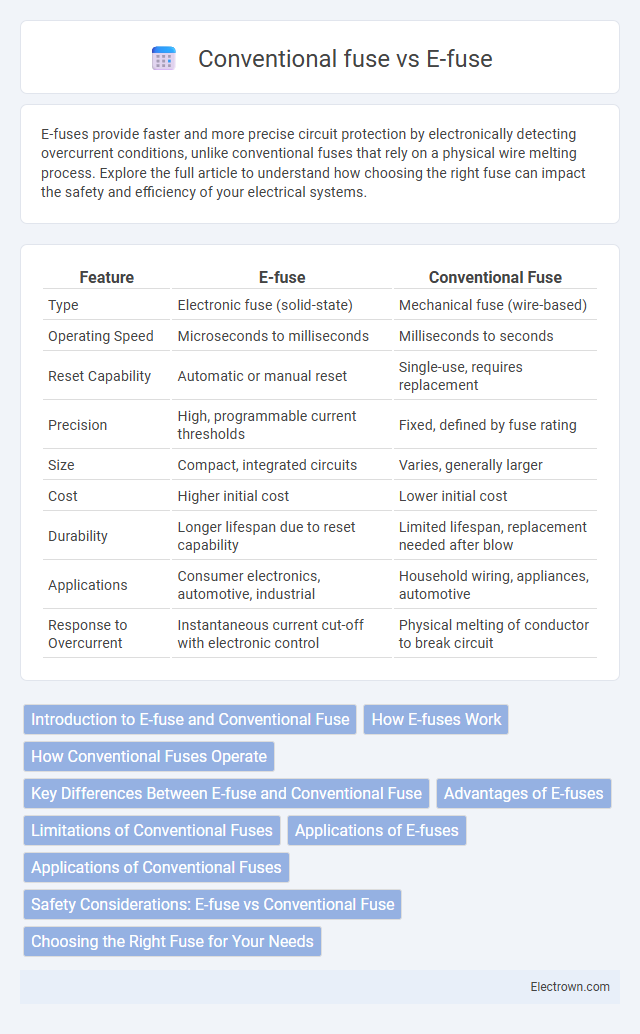

Table of Comparison

| Feature | E-fuse | Conventional Fuse |

|---|---|---|

| Type | Electronic fuse (solid-state) | Mechanical fuse (wire-based) |

| Operating Speed | Microseconds to milliseconds | Milliseconds to seconds |

| Reset Capability | Automatic or manual reset | Single-use, requires replacement |

| Precision | High, programmable current thresholds | Fixed, defined by fuse rating |

| Size | Compact, integrated circuits | Varies, generally larger |

| Cost | Higher initial cost | Lower initial cost |

| Durability | Longer lifespan due to reset capability | Limited lifespan, replacement needed after blow |

| Applications | Consumer electronics, automotive, industrial | Household wiring, appliances, automotive |

| Response to Overcurrent | Instantaneous current cut-off with electronic control | Physical melting of conductor to break circuit |

Introduction to E-fuse and Conventional Fuse

E-fuses are semiconductor-based devices offering precise and fast electrical protection by electronically interrupting current flow during fault conditions, commonly used in modern electronics for enhanced reliability and reset capability. Conventional fuses are physical components containing a metal wire or strip that melts when excessive current flows, providing one-time protection by breaking the circuit and requiring replacement after a fault event. The fundamental difference lies in the E-fuse's ability to reset and integrate into ICs versus the one-time mechanical operation of conventional fuses.

How E-fuses Work

E-fuses operate by using semiconductor technology to detect overcurrent conditions and quickly interrupt the circuit, providing precise and programmable protection. Unlike conventional fuses, which rely on a metal wire melting to break the circuit, E-fuses actively monitor current and reset automatically after fault clearance. Your electronic device benefits from improved reliability and faster response times with E-fuses, enhancing overall circuit safety.

How Conventional Fuses Operate

Conventional fuses operate by housing a metal wire or strip that melts when excessive current flows through, breaking the circuit and preventing damage to electrical components. The melting point of the fuse element is carefully selected to correspond with the maximum current rating, ensuring timely interruption during overcurrent conditions. Understanding how conventional fuses operate can help you choose the right protective device for your electrical systems.

Key Differences Between E-fuse and Conventional Fuse

E-fuses provide precise electronic current limiting and faster response times compared to conventional fuses, which rely on melting a metal wire to interrupts the circuit. E-fuses offer programmability and resettable protection, allowing multiple uses without replacement, while conventional fuses are single-use and require manual replacement after blowing. Thermal performance and integration with modern electronic systems make e-fuses ideal for applications demanding accuracy and compact designs, unlike bulky conventional fuses.

Advantages of E-fuses

E-fuses offer precise electronic protection by automatically resetting after fault conditions, minimizing downtime compared to conventional fuses that require manual replacement. Their fast response time and accurate current sensing improve circuit reliability and prevent damage to sensitive components. Incorporating E-fuses in Your design enhances safety while reducing maintenance costs and improving overall system efficiency.

Limitations of Conventional Fuses

Conventional fuses face limitations such as slower response times and limited capability to handle transient surges, often leading to prolonged equipment exposure to fault conditions. Their single-use design requires replacement after each fault occurrence, increasing maintenance costs and downtime. Additionally, conventional fuses lack precise current monitoring and cannot be easily integrated into modern smart grid systems for real-time fault detection.

Applications of E-fuses

E-fuses are widely used in advanced electronics for precise overcurrent protection in applications such as smartphones, laptops, and automotive systems, where fast response and integration with digital control are critical. Unlike conventional fuses, E-fuses can be reset after tripping, making them ideal for reusable protection in consumer electronics and data centers. Their ability to monitor current and voltage in real-time enhances safety and reliability in sensitive circuit environments.

Applications of Conventional Fuses

Conventional fuses are widely used in residential, automotive, and industrial electrical systems to protect wiring and equipment from overcurrent conditions. Their simplicity and cost-effectiveness make them suitable for safeguarding appliances, motors, and control circuits against short circuits and overloads. Your choice of protection often relies on the dependable and straightforward operation of conventional fuses in these applications.

Safety Considerations: E-fuse vs Conventional Fuse

E-fuses enhance safety by providing precise overcurrent protection with faster response times and integrated thermal monitoring, reducing the risk of electrical faults and fire hazards. Conventional fuses rely on a melting wire to break the circuit, which can cause arc flashes and take longer to react, posing higher risks in sensitive electronic environments. The resettable nature of E-fuses also prevents downtime from fuse replacements, improving operational safety and reliability in critical applications.

Choosing the Right Fuse for Your Needs

Selecting the right fuse involves evaluating the operational environment, current ratings, and response times where E-fuses offer precise electronic protection with fast trip characteristics and resettable capabilities ideal for sensitive circuits. Conventional fuses provide reliable, low-cost overcurrent protection with straightforward installation but require replacement after a fault, suitable for less complex or high-current applications. Understanding the specific electrical load and safety requirements ensures optimal fuse performance and device longevity.

E-fuse vs Conventional fuse Infographic

electrown.com

electrown.com