Oil temperature sensors measure the temperature of the engine oil to ensure optimal lubrication and prevent overheating, while coolant temperature sensors monitor the engine's coolant to regulate its operating temperature and avoid engine damage. Understanding the differences between these two sensors can help you maintain your vehicle's performance more effectively--read on to discover how each impacts your engine.

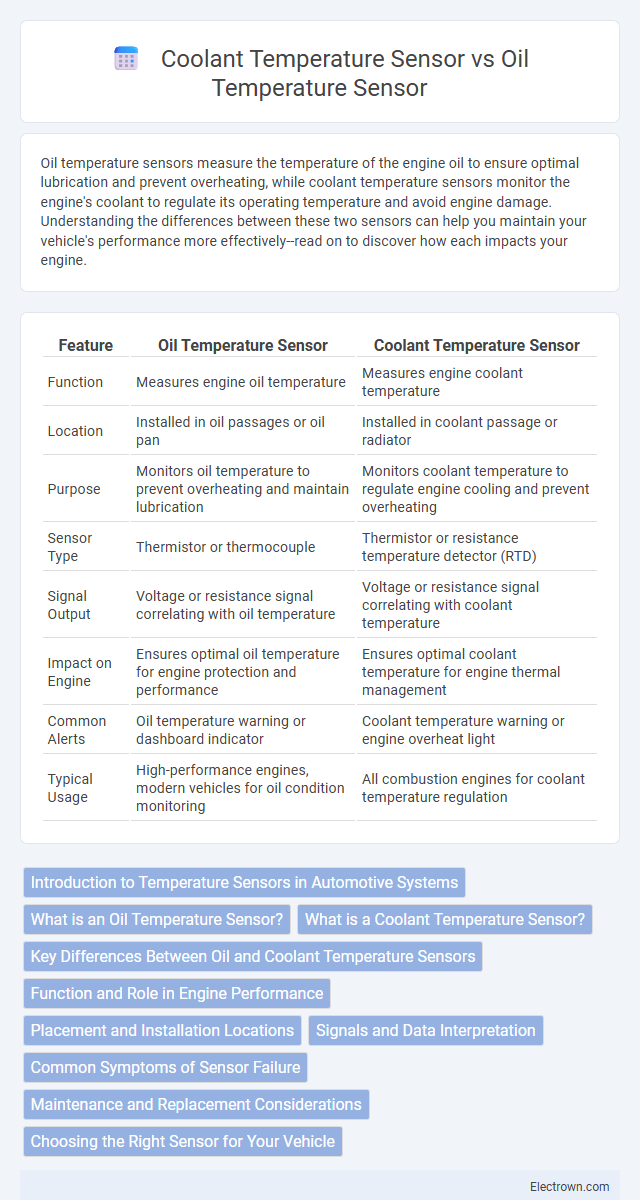

Table of Comparison

| Feature | Oil Temperature Sensor | Coolant Temperature Sensor |

|---|---|---|

| Function | Measures engine oil temperature | Measures engine coolant temperature |

| Location | Installed in oil passages or oil pan | Installed in coolant passage or radiator |

| Purpose | Monitors oil temperature to prevent overheating and maintain lubrication | Monitors coolant temperature to regulate engine cooling and prevent overheating |

| Sensor Type | Thermistor or thermocouple | Thermistor or resistance temperature detector (RTD) |

| Signal Output | Voltage or resistance signal correlating with oil temperature | Voltage or resistance signal correlating with coolant temperature |

| Impact on Engine | Ensures optimal oil temperature for engine protection and performance | Ensures optimal coolant temperature for engine thermal management |

| Common Alerts | Oil temperature warning or dashboard indicator | Coolant temperature warning or engine overheat light |

| Typical Usage | High-performance engines, modern vehicles for oil condition monitoring | All combustion engines for coolant temperature regulation |

Introduction to Temperature Sensors in Automotive Systems

Oil temperature sensors and coolant temperature sensors play critical roles in automotive systems by monitoring engine temperature to ensure optimal performance and prevent overheating. The oil temperature sensor tracks the temperature of the engine oil, which affects lubrication efficiency and engine longevity, while the coolant temperature sensor measures the engine coolant's temperature to regulate the cooling system and maintain engine stability. Your vehicle relies on accurate readings from both sensors to balance engine heat management and maximize efficiency.

What is an Oil Temperature Sensor?

An oil temperature sensor measures the temperature of the engine oil to ensure optimal lubrication and prevent overheating, which can cause engine damage. Unlike a coolant temperature sensor that monitors the engine's coolant temperature to regulate the cooling system, the oil temperature sensor provides vital data for maintaining your engine's efficiency and longevity. Accurate oil temperature readings help in adjusting engine performance and protecting internal components under varying driving conditions.

What is a Coolant Temperature Sensor?

A Coolant Temperature Sensor measures the temperature of the engine's coolant to monitor overheating and ensure optimal engine performance. This sensor provides critical data to the engine control unit (ECU), helping regulate fuel injection and ignition timing for Your vehicle's efficiency and safety. Unlike the Oil Temperature Sensor, which tracks engine oil temperature, the Coolant Temperature Sensor focuses on preventing engine overheating by managing coolant heat levels.

Key Differences Between Oil and Coolant Temperature Sensors

Oil temperature sensors measure the temperature of the engine oil to ensure optimal lubrication and prevent overheating, while coolant temperature sensors monitor the engine coolant temperature to avoid engine overheating and maintain efficient cooling system performance. Oil sensors typically use thermistors or resistance temperature detectors (RTDs) placed in the oil passages, whereas coolant sensors are often mounted in the radiator or engine block. Understanding the key differences in sensor placement, function, and monitored fluid helps you maintain engine health and diagnose temperature-related issues accurately.

Function and Role in Engine Performance

The oil temperature sensor monitors the temperature of engine oil to ensure optimal lubrication and prevent overheating, directly influencing engine wear and efficiency. The coolant temperature sensor measures the temperature of the engine coolant to regulate engine cooling, maintain optimal operating temperature, and prevent overheating or freezing. Both sensors play crucial roles in engine performance by providing essential data for the engine control unit (ECU) to adjust fuel injection, ignition timing, and cooling system operation.

Placement and Installation Locations

Oil temperature sensors are typically placed directly in the engine oil passages or oil filter housing to monitor the precise temperature of the engine oil, ensuring optimal lubrication performance. Coolant temperature sensors are installed in the engine's cooling system, commonly near the thermostat or on the cylinder head, measuring the temperature of the engine coolant to regulate engine temperature and prevent overheating. Understanding the specific placement of these sensors helps you maintain accurate readings essential for engine health and performance control.

Signals and Data Interpretation

Oil temperature sensors measure the temperature of engine oil by sending voltage signals that vary according to oil temperature changes, enabling precise monitoring for optimal lubrication and engine protection. Coolant temperature sensors detect the engine coolant's temperature, providing data through varying resistance or voltage signals crucial for regulating engine cooling and managing fuel injection timing. Both sensors generate electrical signals interpreted by the engine control unit (ECU), but oil sensors focus on lubrication efficiency while coolant sensors are vital for thermal management and preventing overheating.

Common Symptoms of Sensor Failure

Oil temperature sensor failure often causes inaccurate engine oil temperature readings, leading to engine overheating or poor fuel efficiency. Coolant temperature sensor issues typically result in erratic temperature gauge behavior, engine overheating, or difficulty starting the engine due to incorrect coolant temperature data. Your vehicle may also experience increased emissions and reduced engine performance when either sensor malfunctions.

Maintenance and Replacement Considerations

Oil temperature sensors and coolant temperature sensors require regular inspection to ensure accurate engine performance monitoring, as faulty sensors can lead to overheating or inefficient fuel consumption. Oil temperature sensors often face contamination from engine oil degradation, necessitating periodic cleaning or replacement every 50,000 to 70,000 miles, while coolant temperature sensors may fail due to corrosion or coolant quality issues, typically needing replacement every 60,000 miles or during coolant system flushes. Your vehicle's maintenance schedule should prioritize timely sensor diagnostics to prevent engine damage and maintain optimal operational efficiency.

Choosing the Right Sensor for Your Vehicle

Selecting the right sensor for your vehicle depends on monitoring specific engine conditions: an oil temperature sensor measures the engine oil temperature to ensure optimal lubrication and prevent overheating, while a coolant temperature sensor tracks the engine coolant temperature to avoid engine overheating and maintain efficient cooling system performance. Factors to consider include the vehicle's make and model, engine type, and the conditions under which the vehicle operates, as some vehicles require both sensors to accurately monitor different aspects of engine temperature. Using the correct sensor ensures accurate data for the engine control unit (ECU), enhancing engine performance, fuel efficiency, and preventing potential mechanical failures.

Oil temperature sensor vs Coolant temperature sensor Infographic

electrown.com

electrown.com