Crank sensors monitor the position and rotational speed of the crankshaft, crucial for engine timing and fuel injection, while cam sensors track the camshaft's position to control valve timing and ignition sequences. Understanding the distinct roles of these sensors helps you diagnose engine performance issues; read the rest of the article to learn how each sensor affects your vehicle's operation.

Table of Comparison

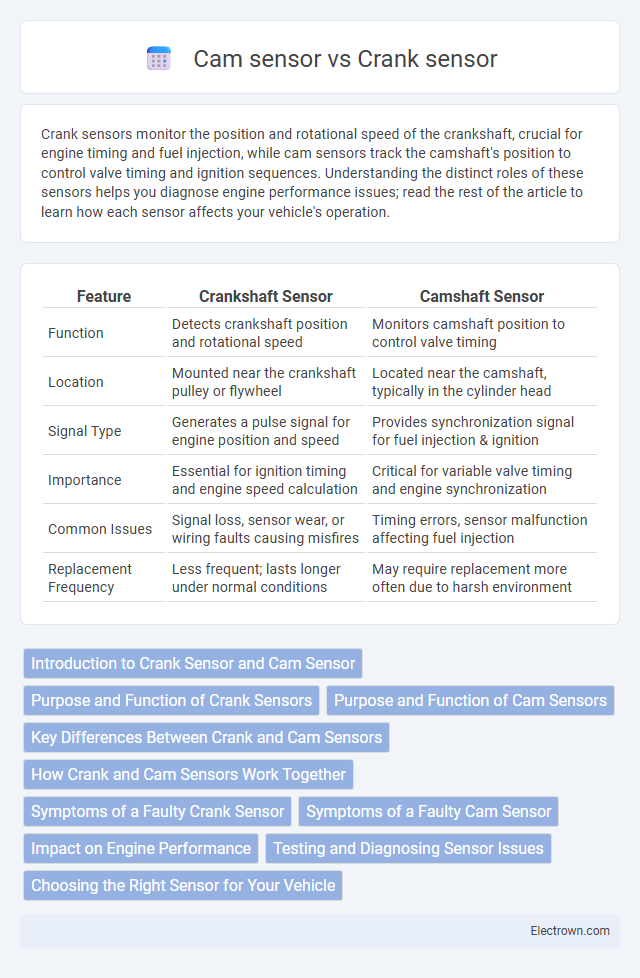

| Feature | Crankshaft Sensor | Camshaft Sensor |

|---|---|---|

| Function | Detects crankshaft position and rotational speed | Monitors camshaft position to control valve timing |

| Location | Mounted near the crankshaft pulley or flywheel | Located near the camshaft, typically in the cylinder head |

| Signal Type | Generates a pulse signal for engine position and speed | Provides synchronization signal for fuel injection & ignition |

| Importance | Essential for ignition timing and engine speed calculation | Critical for variable valve timing and engine synchronization |

| Common Issues | Signal loss, sensor wear, or wiring faults causing misfires | Timing errors, sensor malfunction affecting fuel injection |

| Replacement Frequency | Less frequent; lasts longer under normal conditions | May require replacement more often due to harsh environment |

Introduction to Crank Sensor and Cam Sensor

Crank sensors monitor the position and rotational speed of the crankshaft, providing critical data for engine timing and fuel injection. Cam sensors track the camshaft's position, ensuring precise valve timing for optimal engine performance. Understanding the distinct roles of these sensors helps you maintain engine efficiency and diagnose performance issues effectively.

Purpose and Function of Crank Sensors

Crank sensors monitor the crankshaft's position and rotational speed, providing critical input to the engine control unit (ECU) for precise ignition timing and fuel injection. These sensors detect the crankshaft's angular position by reading a toothed wheel or reluctor ring, ensuring accurate engine timing and optimal performance. Unlike cam sensors that track camshaft position for valve timing, crank sensors directly influence engine start-up and running stability by synchronizing crankshaft movement.

Purpose and Function of Cam Sensors

Cam sensors monitor the position and rotational speed of the camshaft to ensure precise timing of fuel injection and ignition events. By providing real-time data to the engine control unit (ECU), cam sensors help synchronize valve operation with piston movement, enhancing engine efficiency and performance. Your vehicle relies on accurate cam sensor readings to maintain optimal combustion timing and reduce emissions.

Key Differences Between Crank and Cam Sensors

Crank sensors detect the position and rotational speed of the crankshaft to precisely time engine ignition and fuel injection, while cam sensors monitor the camshaft's position to control valve timing. Crank sensors typically use magnetic or Hall effect technology to generate pulses per revolution, providing real-time engine speed data essential for engine management systems. Cam sensors, by contrast, ensure synchronization between the camshaft and crankshaft for accurate valve timing and are crucial for sequential fuel injection and variable valve timing mechanisms.

How Crank and Cam Sensors Work Together

Crankshaft and camshaft sensors work together by providing critical data to the engine control unit (ECU) for precise timing and fuel injection. The crank sensor monitors the crankshaft's position and rotational speed, while the cam sensor detects the camshaft's position to determine which cylinder is firing. This synchronization ensures your engine runs efficiently, optimizing performance and reducing emissions.

Symptoms of a Faulty Crank Sensor

A faulty crank sensor often causes engine misfires, stalling, or difficulty starting, as it disrupts the engine's timing and fuel injection. You may experience erratic idle, poor acceleration, or a complete failure to start if the sensor fails to send accurate rotation data to the engine control unit (ECU). Diagnosing these symptoms early can prevent more severe engine damage and ensure your vehicle runs smoothly.

Symptoms of a Faulty Cam Sensor

Symptoms of a faulty cam sensor include engine misfires, rough idling, and difficulty starting the vehicle. Your engine control unit may also experience timing issues, leading to poor acceleration and reduced fuel efficiency. Diagnostic trouble codes such as P0340 often indicate cam sensor malfunctions.

Impact on Engine Performance

The crank sensor and cam sensor play critical roles in engine performance by providing precise timing data for fuel injection and ignition systems. The crank sensor monitors the crankshaft position and rotational speed, directly influencing engine timing accuracy and smooth operation, while the cam sensor detects camshaft position to ensure proper valve timing and synchronization. Faulty signals from either sensor can lead to misfires, poor fuel efficiency, and decreased overall engine performance.

Testing and Diagnosing Sensor Issues

Testing crank sensors involves measuring AC voltage or resistance with a multimeter while rotating the engine, as it detects engine speed by monitoring crankshaft position. Camshaft sensors are tested by checking signal voltage output or resistance, often requiring an oscilloscope to verify the timing of camshaft rotation relative to crankshaft signals. Accurate diagnosis of sensor issues relies on interpreting sensor signal waveforms and fault codes using an OBD-II scanner to identify misfires or timing discrepancies.

Choosing the Right Sensor for Your Vehicle

Selecting between a crankshaft sensor and a camshaft sensor depends on your vehicle's engine management needs, as the crank sensor monitors engine speed and position, while the cam sensor tracks valve timing. Your choice impacts fuel injection timing, ignition, and overall engine performance, making it crucial to match the sensor with your vehicle's specific engine type. Proper sensor selection ensures accurate engine synchronization and optimal driving efficiency.

Crank sensor vs Cam sensor Infographic

electrown.com

electrown.com