Drive-by-wire systems replace traditional throttle cables with electronic sensors and actuators, offering precise control and improved fuel efficiency by electronically regulating engine power. Discover how these technologies impact your vehicle's performance and maintenance by diving deeper into the differences.

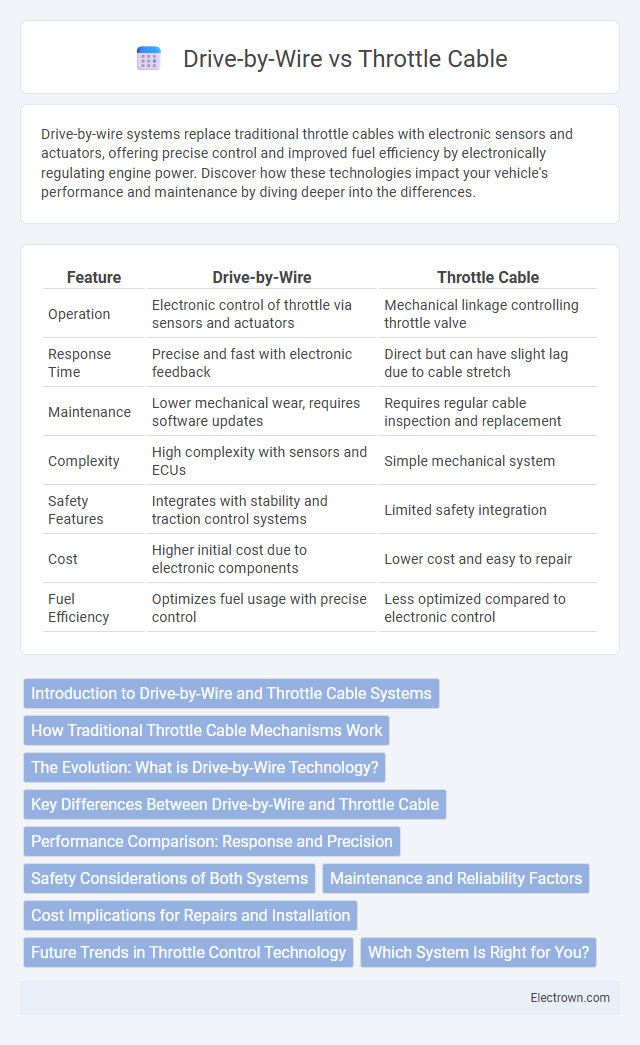

Table of Comparison

| Feature | Drive-by-Wire | Throttle Cable |

|---|---|---|

| Operation | Electronic control of throttle via sensors and actuators | Mechanical linkage controlling throttle valve |

| Response Time | Precise and fast with electronic feedback | Direct but can have slight lag due to cable stretch |

| Maintenance | Lower mechanical wear, requires software updates | Requires regular cable inspection and replacement |

| Complexity | High complexity with sensors and ECUs | Simple mechanical system |

| Safety Features | Integrates with stability and traction control systems | Limited safety integration |

| Cost | Higher initial cost due to electronic components | Lower cost and easy to repair |

| Fuel Efficiency | Optimizes fuel usage with precise control | Less optimized compared to electronic control |

Introduction to Drive-by-Wire and Throttle Cable Systems

Drive-by-wire systems replace traditional throttle cables with electronic sensors and actuators that control the throttle electronically, improving precision and response time. Throttle cable systems use a physical cable connected to the accelerator pedal, directly opening the throttle valve for engine speed control. Understanding these systems helps you appreciate advancements in automotive technology and their impact on vehicle performance and maintenance.

How Traditional Throttle Cable Mechanisms Work

Traditional throttle cable mechanisms use a physical cable that connects the accelerator pedal to the throttle body, transmitting your foot's movement directly to control engine air intake. When you press the pedal, the cable pulls a lever on the throttle body, opening the throttle valve to regulate airflow and engine speed. This mechanical linkage offers straightforward responsiveness but lacks the adaptive precision found in modern drive-by-wire systems.

The Evolution: What is Drive-by-Wire Technology?

Drive-by-wire technology replaces traditional mechanical throttle cables with electronic sensors and actuators to control the engine's throttle. This system enhances precision, responsiveness, and integrates seamlessly with advanced vehicle safety and efficiency features. Your driving experience benefits from smoother acceleration and improved fuel management due to this evolution in automotive control systems.

Key Differences Between Drive-by-Wire and Throttle Cable

Drive-by-wire systems replace traditional throttle cables with electronic sensors and actuators, enabling precise throttle control through a computer interface. Throttle cables mechanically link the accelerator pedal to the engine throttle valve, offering direct but less flexible control. Drive-by-wire improves fuel efficiency and responsiveness by enabling adaptive throttle mapping, while throttle cables provide simplicity and reliability without electronic dependency.

Performance Comparison: Response and Precision

Drive-by-wire systems offer superior response and precision compared to traditional throttle cable mechanisms by utilizing electronic sensors and actuators that adjust throttle position instantly based on the driver's input. Throttle cable systems rely on mechanical linkages that can introduce slight delays and less consistent throttle modulation due to cable stretch and wear. The enhanced accuracy of drive-by-wire technology improves engine efficiency and acceleration smoothness, providing a more responsive and controlled driving experience.

Safety Considerations of Both Systems

Drive-by-wire systems enhance safety by providing more precise throttle control and integrating with electronic stability and traction control systems, reducing the risk of unintended acceleration. Throttle cable systems, while mechanical and simpler, may suffer from wear and tear leading to potential throttle sticking or delayed response, posing safety risks if not regularly maintained. Your vehicle's safety significantly benefits from drive-by-wire technology's ability to enable rapid electronic intervention during emergency conditions.

Maintenance and Reliability Factors

Drive-by-wire systems reduce maintenance needs by eliminating mechanical linkages prone to wear and requiring adjustment, relying instead on electronic sensors and actuators for throttle control. Throttle cables can suffer from stretching, fraying, and corrosion, necessitating regular inspection and replacement to maintain reliability. The electronic precision of drive-by-wire enhances consistent throttle response but depends on sensor calibration and software integrity for optimal performance.

Cost Implications for Repairs and Installation

Drive-by-wire systems generally incur higher repair and installation costs due to their reliance on electronic sensors, actuators, and sophisticated control modules compared to traditional throttle cable setups. Throttle cable repairs are typically less expensive and simpler, as they involve mechanical adjustments or replacements without the need for specialized diagnostic tools. Your choice between the two should consider not only upfront installation expenses but also the potential long-term maintenance costs and technological complexity.

Future Trends in Throttle Control Technology

Drive-by-wire throttle control is rapidly advancing with integration of AI and IoT technologies, enhancing real-time responsiveness and precision in engine management systems. Emerging trends emphasize electric and autonomous vehicles, where drive-by-wire systems enable seamless integration with advanced driver-assistance systems (ADAS) for improved safety and efficiency. Throttle cable systems are gradually being phased out due to their mechanical limitations, giving way to more adaptive and customizable electronic throttle control solutions.

Which System Is Right for You?

Drive-by-wire systems offer precise electronic control and improved fuel efficiency by replacing traditional throttle cables with sensors and actuators, making them ideal for modern vehicles focused on performance and emissions. Throttle cable systems provide a direct mechanical link between the accelerator pedal and engine throttle, offering simplicity, reliability, and easier maintenance, which may suit older vehicles or those requiring straightforward repairs. Your choice depends on whether you prioritize advanced technology with electronic integration or the proven dependability of mechanical control.

Drive-by-wire vs Throttle cable Infographic

electrown.com

electrown.com