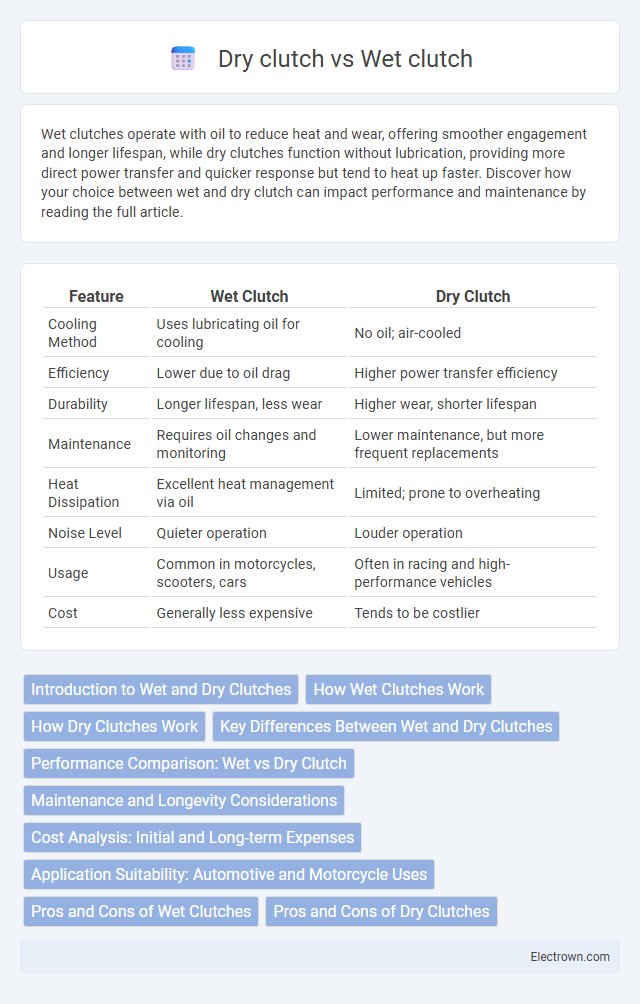

Wet clutches operate with oil to reduce heat and wear, offering smoother engagement and longer lifespan, while dry clutches function without lubrication, providing more direct power transfer and quicker response but tend to heat up faster. Discover how your choice between wet and dry clutch can impact performance and maintenance by reading the full article.

Table of Comparison

| Feature | Wet Clutch | Dry Clutch |

|---|---|---|

| Cooling Method | Uses lubricating oil for cooling | No oil; air-cooled |

| Efficiency | Lower due to oil drag | Higher power transfer efficiency |

| Durability | Longer lifespan, less wear | Higher wear, shorter lifespan |

| Maintenance | Requires oil changes and monitoring | Lower maintenance, but more frequent replacements |

| Heat Dissipation | Excellent heat management via oil | Limited; prone to overheating |

| Noise Level | Quieter operation | Louder operation |

| Usage | Common in motorcycles, scooters, cars | Often in racing and high-performance vehicles |

| Cost | Generally less expensive | Tends to be costlier |

Introduction to Wet and Dry Clutches

Wet clutches operate immersed in oil, providing smoother engagement and better heat dissipation, making them ideal for motorcycles and automatic transmissions. Dry clutches function without lubrication, offering more direct power transfer and lighter weight, commonly found in sports cars and motorcycles requiring quick response. Understanding the differences will help you select the right clutch system for performance and durability needs.

How Wet Clutches Work

Wet clutches operate by immersing the clutch plates in a cooling lubricant, which reduces friction and dissipates heat during engagement and disengagement. This design improves durability and smoothness, especially in high-torque or heavy-duty applications. Your vehicle's wet clutch ensures consistent performance by maintaining optimal temperature and reducing wear over time.

How Dry Clutches Work

Dry clutches operate by pressing friction plates together without oil immersion, enabling a direct transfer of power from the engine to the transmission. This design reduces energy loss and provides quicker response times compared to wet clutches, which rely on oil for cooling and lubrication. Your vehicle's performance benefits from the dry clutch's ability to handle higher temperatures and harsher conditions without fluid contamination.

Key Differences Between Wet and Dry Clutches

Wet clutches operate with lubrication, using oil to dissipate heat and reduce wear, making them ideal for smoother engagement and longer durability in motorcycles and automatic transmissions. Dry clutches function without oil, providing a more direct connection and quicker response, often preferred in high-performance or racing vehicles for their immediate power transfer. Understanding these key differences helps you choose the right clutch type based on your vehicle's performance needs and maintenance preferences.

Performance Comparison: Wet vs Dry Clutch

Wet clutches offer superior cooling and durability due to continuous lubrication, making them ideal for high-performance or heavy-duty applications where heat dissipation is critical. Dry clutches, while providing a more direct power transfer and lighter weight, tend to wear faster and generate more heat under intense use. Your choice between wet and dry clutches should weigh the balance between performance efficiency, maintenance frequency, and specific driving conditions.

Maintenance and Longevity Considerations

Wet clutches require regular oil changes and fluid checks to prevent contamination and wear, extending their lifespan with proper maintenance. Dry clutches demand less frequent service but are more prone to overheating and faster wear under heavy use, reducing longevity without timely replacement. Your choice affects maintenance schedules and durability based on riding conditions and mechanical design.

Cost Analysis: Initial and Long-term Expenses

Wet clutch systems typically incur higher initial costs due to their complex design and the need for oil cooling components, but offer lower long-term maintenance expenses thanks to better heat dissipation and reduced wear. Dry clutches have a simpler and cheaper initial setup, yet they often demand more frequent replacements and repairs, leading to increased expenses over time. Your choice between wet and dry clutch systems should consider both upfront investment and ongoing maintenance budgets to ensure cost efficiency.

Application Suitability: Automotive and Motorcycle Uses

Wet clutches excel in automotive and motorcycle applications requiring smooth engagement and efficient heat dissipation, making them ideal for high-performance and heavy-duty vehicles. Dry clutches suit lightweight motorcycles and racing cars where direct power transfer and minimal drag improve acceleration and responsiveness. Your choice depends on factors like heat management, durability, and vehicle type to optimize driving or riding performance.

Pros and Cons of Wet Clutches

Wet clutches provide superior cooling and durability, making them ideal for high-performance motorcycles and heavy machinery due to their ability to operate smoothly under continuous engagement. They require regular maintenance to prevent oil contamination, which can reduce friction efficiency and cause slippage. However, wet clutches tend to have lower power transmission efficiency compared to dry clutches because of oil drag and increased friction.

Pros and Cons of Dry Clutches

Dry clutches offer several advantages, including a lighter weight and simpler design, leading to quicker response times and reduced maintenance due to the absence of oil contamination. However, they tend to generate more heat and wear faster under heavy use, which can result in louder operation and shorter lifespan compared to wet clutches. Your choice between dry and wet clutches should consider factors like performance needs, durability, and maintenance preferences.

Wet clutch vs Dry clutch Infographic

electrown.com

electrown.com