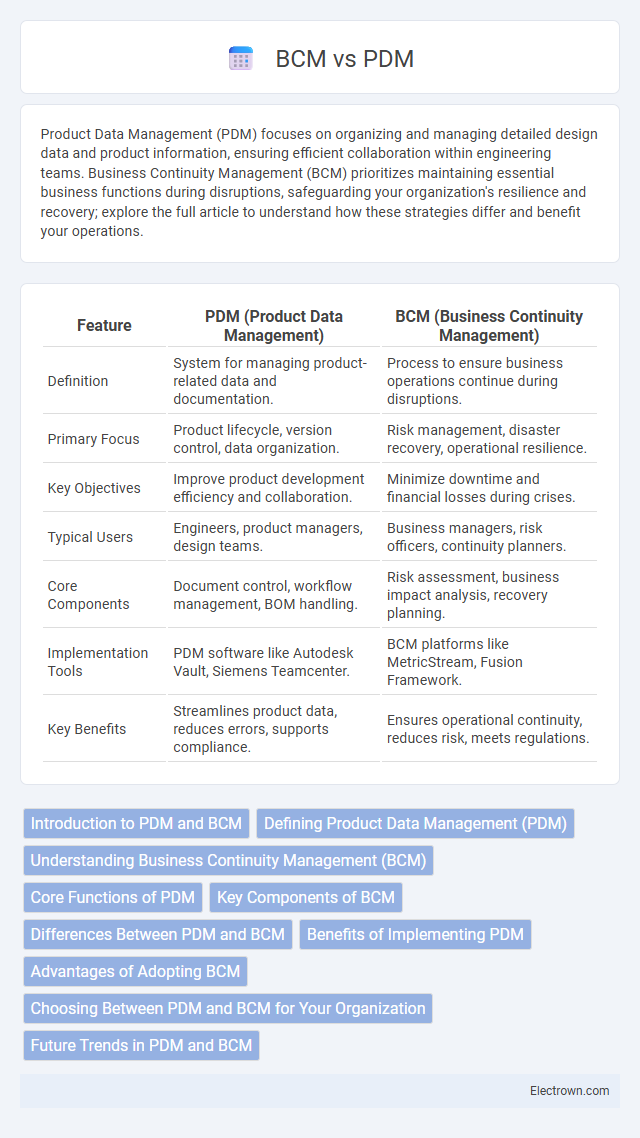

Product Data Management (PDM) focuses on organizing and managing detailed design data and product information, ensuring efficient collaboration within engineering teams. Business Continuity Management (BCM) prioritizes maintaining essential business functions during disruptions, safeguarding your organization's resilience and recovery; explore the full article to understand how these strategies differ and benefit your operations.

Table of Comparison

| Feature | PDM (Product Data Management) | BCM (Business Continuity Management) |

|---|---|---|

| Definition | System for managing product-related data and documentation. | Process to ensure business operations continue during disruptions. |

| Primary Focus | Product lifecycle, version control, data organization. | Risk management, disaster recovery, operational resilience. |

| Key Objectives | Improve product development efficiency and collaboration. | Minimize downtime and financial losses during crises. |

| Typical Users | Engineers, product managers, design teams. | Business managers, risk officers, continuity planners. |

| Core Components | Document control, workflow management, BOM handling. | Risk assessment, business impact analysis, recovery planning. |

| Implementation Tools | PDM software like Autodesk Vault, Siemens Teamcenter. | BCM platforms like MetricStream, Fusion Framework. |

| Key Benefits | Streamlines product data, reduces errors, supports compliance. | Ensures operational continuity, reduces risk, meets regulations. |

Introduction to PDM and BCM

Product Data Management (PDM) systems organize and control product information, enabling efficient collaboration and version control throughout the product lifecycle. Business Continuity Management (BCM) involves strategic planning and processes to ensure critical business functions continue during and after disruptions. While PDM focuses on managing product-related data, BCM safeguards overall organizational resilience against operational risks.

Defining Product Data Management (PDM)

Product Data Management (PDM) involves the centralized control and organization of product-related information throughout its lifecycle, ensuring accurate and accessible data for engineering and manufacturing teams. PDM systems manage design files, version history, bill of materials, and documentation to streamline product development processes and reduce errors. This structure enhances collaboration by providing a single source of truth, improving product consistency and accelerating time-to-market.

Understanding Business Continuity Management (BCM)

Business Continuity Management (BCM) is a strategic approach that ensures critical business functions continue during and after a disruption, minimizing operational risks and financial losses. BCM involves comprehensive risk assessment, business impact analysis, and development of recovery strategies tailored to specific organizational needs. This proactive planning encompasses crisis management, emergency response, and communication protocols to maintain resilience against natural disasters, cyberattacks, and other potential threats.

Core Functions of PDM

Product Data Management (PDM) primarily focuses on organizing and controlling product-related information such as CAD files, technical specifications, and version histories to enhance collaboration and reduce errors in product development. Its core functions include centralized data storage, revision control, workflow management, and access control to ensure accurate and up-to-date product information throughout the lifecycle. PDM systems streamline design processes by enabling efficient data sharing and maintaining an audit trail for compliance and traceability.

Key Components of BCM

Business Continuity Management (BCM) encompasses key components such as risk assessment, business impact analysis, recovery strategies, and plan development, ensuring organizational resilience during disruptions. These elements systematically identify threats, evaluate critical functions, and implement procedures to maintain essential operations. Effective BCM integrates communication plans and continuous testing to enhance readiness and minimize downtime.

Differences Between PDM and BCM

PDM (Product Data Management) focuses on organizing and controlling design data and product-related information throughout development, while BCM (Business Continuity Management) centers on preparing and responding to operational disruptions to ensure business resilience. PDM primarily manages technical documents, CAD files, and version control, supporting engineering workflows, whereas BCM involves risk assessments, disaster recovery plans, and crisis management protocols to maintain critical business functions. Understanding these key differences helps you implement the right system according to your company's priorities--product lifecycle optimization or operational continuity.

Benefits of Implementing PDM

Implementing Product Data Management (PDM) streamlines the organization and control of product information, enhancing collaboration across engineering, manufacturing, and design teams. PDM improves version control, reduces errors, and accelerates product development cycles, leading to higher efficiency and reduced time-to-market. By centralizing product data, your company gains greater visibility and traceability, ensuring consistency and quality throughout the product lifecycle.

Advantages of Adopting BCM

Business Continuity Management (BCM) ensures organizational resilience by preparing for, responding to, and recovering from disruptions, minimizing downtime and financial losses. Unlike Product Data Management (PDM), which focuses on managing product information, BCM delivers comprehensive risk mitigation by integrating crisis management, disaster recovery, and business impact analysis. The strategic adoption of BCM enhances stakeholder confidence and regulatory compliance, safeguarding critical processes and maintaining operational stability.

Choosing Between PDM and BCM for Your Organization

Choosing between Product Data Management (PDM) and Business Continuity Management (BCM) depends on your organization's primary needs: PDM streamlines product lifecycle and engineering data to enhance collaboration and reduce errors, while BCM focuses on risk mitigation and ensuring operational resilience during disruptions. Assessing your core priorities--whether improving product development efficiency or safeguarding business processes against crises--guides the optimal choice. Investing in the appropriate system aligns your operational strategy with long-term organizational goals.

Future Trends in PDM and BCM

Future trends in Product Data Management (PDM) emphasize integration with Artificial Intelligence (AI) and Internet of Things (IoT) technologies to enhance real-time data accuracy and collaboration across product lifecycles. Business Continuity Management (BCM) is evolving with advanced predictive analytics and cloud-based disaster recovery solutions to ensure faster response and resilience against cyber threats or natural disasters. Your organization can leverage these innovations to streamline workflows in PDM while strengthening risk mitigation and operational safeguards in BCM.

PDM vs BCM Infographic

electrown.com

electrown.com