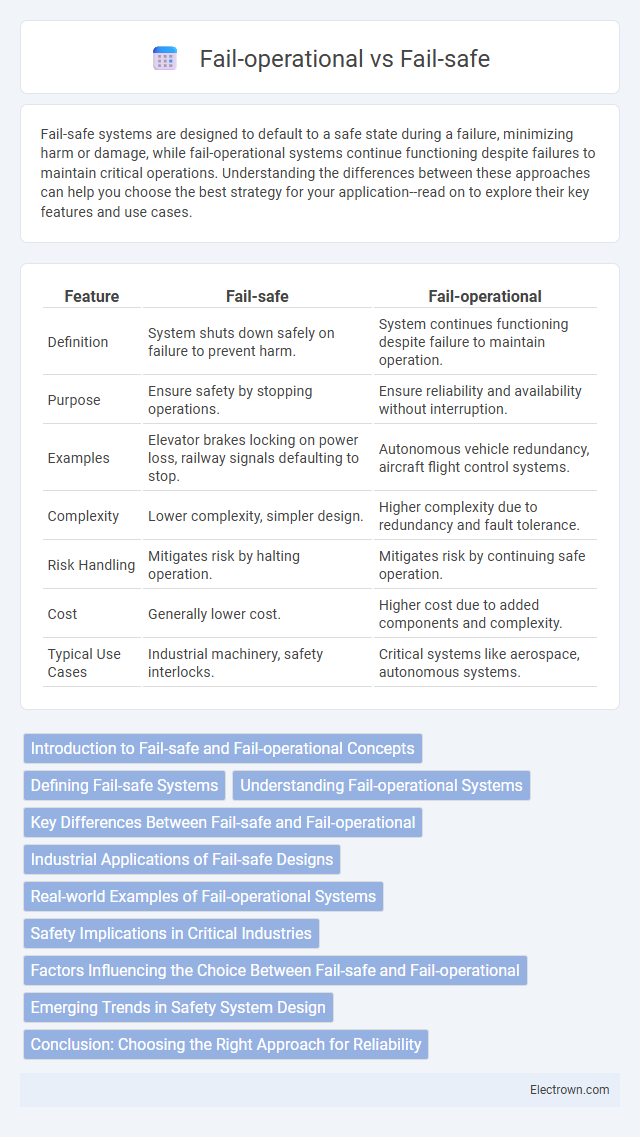

Fail-safe systems are designed to default to a safe state during a failure, minimizing harm or damage, while fail-operational systems continue functioning despite failures to maintain critical operations. Understanding the differences between these approaches can help you choose the best strategy for your application--read on to explore their key features and use cases.

Table of Comparison

| Feature | Fail-safe | Fail-operational |

|---|---|---|

| Definition | System shuts down safely on failure to prevent harm. | System continues functioning despite failure to maintain operation. |

| Purpose | Ensure safety by stopping operations. | Ensure reliability and availability without interruption. |

| Examples | Elevator brakes locking on power loss, railway signals defaulting to stop. | Autonomous vehicle redundancy, aircraft flight control systems. |

| Complexity | Lower complexity, simpler design. | Higher complexity due to redundancy and fault tolerance. |

| Risk Handling | Mitigates risk by halting operation. | Mitigates risk by continuing safe operation. |

| Cost | Generally lower cost. | Higher cost due to added components and complexity. |

| Typical Use Cases | Industrial machinery, safety interlocks. | Critical systems like aerospace, autonomous systems. |

Introduction to Fail-safe and Fail-operational Concepts

Fail-safe systems are designed to default to a safe state in case of failure, minimizing harm or damage by halting operations. Fail-operational systems maintain functionality even during component failures, ensuring continuous performance without interruption. These concepts are critical in industries like automotive, aerospace, and industrial automation to balance safety and reliability.

Defining Fail-safe Systems

Fail-safe systems are designed to default to a safe mode in the event of a failure, preventing harm or damage by shutting down or entering a non-operational state. These systems prioritize safety by ensuring that any malfunction triggers protective measures, effectively minimizing risk. Common applications include industrial machinery, transportation systems, and medical devices where uncontrolled operation could lead to catastrophic consequences.

Understanding Fail-operational Systems

Fail-operational systems maintain continuous functionality despite failures by switching to backup components or redundant systems, ensuring zero downtime in critical applications like autonomous vehicles and aerospace. These systems differ from fail-safe designs, which prioritize safety by shutting down operations when a fault occurs to prevent harm. Understanding fail-operational systems involves analyzing fault tolerance mechanisms, real-time monitoring, and automatic recovery processes critical for mission-critical environments.

Key Differences Between Fail-safe and Fail-operational

Fail-safe systems prioritize safety by transitioning to a safe state or shutting down upon failure, preventing harm but stopping operation. Fail-operational systems maintain functionality despite faults, ensuring continuous operation without interruption, critical for applications like autonomous vehicles or aerospace. The key difference lies in fail-safe systems halting processes to avoid danger, while fail-operational systems enable ongoing performance even during faults.

Industrial Applications of Fail-safe Designs

Fail-safe designs are critical in industrial applications where system failure must not result in hazardous conditions, such as emergency shutdown systems in chemical plants or power generation facilities to prevent accidents. These designs ensure systems default to a safe state upon failure, minimizing risks to personnel and equipment. Common implementations include fail-safe valves, relays, and control circuits that deactivate or isolate affected components during faults.

Real-world Examples of Fail-operational Systems

Fail-operational systems maintain functionality despite component failures, evident in aircraft flight control systems where multiple redundant computers ensure continuous operation during faults. Autonomous vehicles employ fail-operational designs with backup sensors and processors to safely navigate even if primary systems malfunction. In industrial automation, fail-operational robots continue performing critical tasks without interruption, minimizing downtime and maintaining production efficiency.

Safety Implications in Critical Industries

Fail-safe systems prioritize bringing operations to a safe halt during faults to prevent harm, crucial in industries like railways and nuclear power where immediate risk mitigation is essential. Fail-operational systems maintain function despite failures, enabling continuous operation in aerospace and autonomous vehicles, where uninterrupted performance ensures safety. Your choice between fail-safe and fail-operational impacts risk management strategies and compliance with safety standards in critical industries.

Factors Influencing the Choice Between Fail-safe and Fail-operational

The choice between fail-safe and fail-operational systems depends on factors such as the criticality of continuous operation, safety requirements, and potential consequences of failure. In environments where uninterrupted functionality is crucial, like autonomous vehicles or aerospace, fail-operational designs ensure your system maintains operation despite faults. Conversely, systems prioritizing risk mitigation and controlled shutdown, like industrial safety mechanisms, favor fail-safe designs to minimize harm during failures.

Emerging Trends in Safety System Design

Emerging trends in safety system design emphasize the integration of fail-operational architectures, enabling critical systems to maintain functionality despite failures. Advanced sensor fusion, real-time diagnostics, and redundancy protocols enhance fail-operational capabilities, reducing downtime and improving reliability compared to traditional fail-safe designs. Industry standards increasingly favor fail-operational systems in autonomous vehicles and aerospace to ensure uninterrupted safety performance under adverse conditions.

Conclusion: Choosing the Right Approach for Reliability

Fail-safe systems prioritize safety by shutting down operations upon failure, minimizing risks in critical environments such as aerospace and medical devices. Fail-operational systems continue functioning despite faults, ensuring uninterrupted service crucial for autonomous vehicles and industrial automation. Selecting the right reliability approach depends on the application's safety requirements, operational continuity needs, and acceptable risk levels.

Fail-safe vs Fail-operational Infographic

electrown.com

electrown.com