The MAF sensor measures the actual amount of air entering the engine to optimize fuel injection, while the MAP sensor monitors the manifold pressure to infer engine load and adjust fuel delivery accordingly. Understanding the differences between these sensors can help you diagnose performance issues and improve engine efficiency--read on to explore their functions in detail.

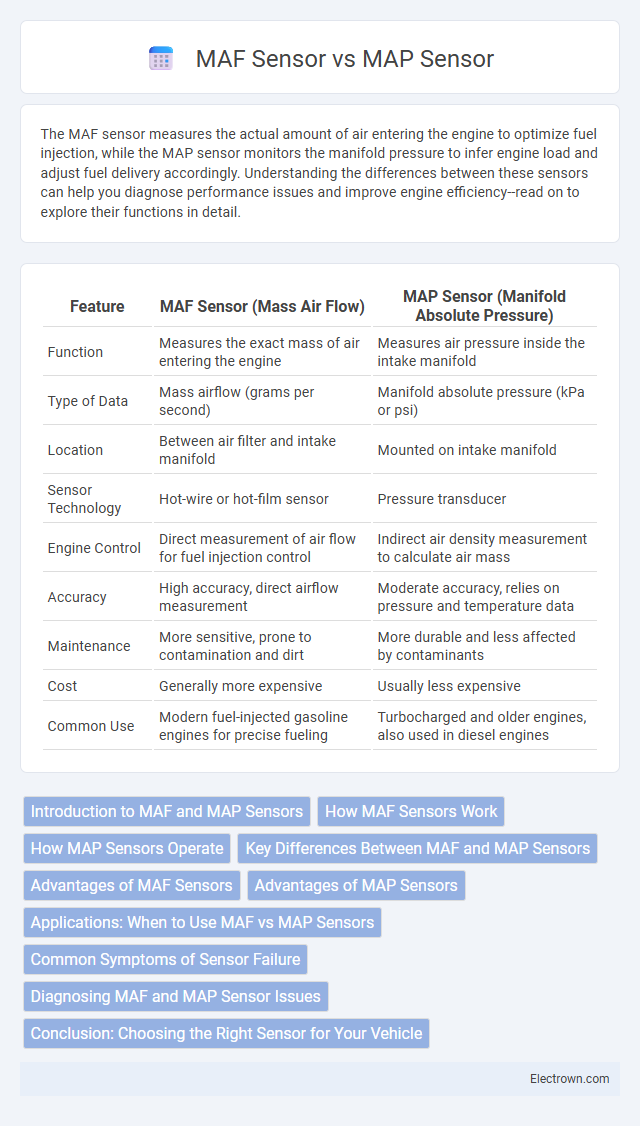

Table of Comparison

| Feature | MAF Sensor (Mass Air Flow) | MAP Sensor (Manifold Absolute Pressure) |

|---|---|---|

| Function | Measures the exact mass of air entering the engine | Measures air pressure inside the intake manifold |

| Type of Data | Mass airflow (grams per second) | Manifold absolute pressure (kPa or psi) |

| Location | Between air filter and intake manifold | Mounted on intake manifold |

| Sensor Technology | Hot-wire or hot-film sensor | Pressure transducer |

| Engine Control | Direct measurement of air flow for fuel injection control | Indirect air density measurement to calculate air mass |

| Accuracy | High accuracy, direct airflow measurement | Moderate accuracy, relies on pressure and temperature data |

| Maintenance | More sensitive, prone to contamination and dirt | More durable and less affected by contaminants |

| Cost | Generally more expensive | Usually less expensive |

| Common Use | Modern fuel-injected gasoline engines for precise fueling | Turbocharged and older engines, also used in diesel engines |

Introduction to MAF and MAP Sensors

MAF sensors measure the mass of air entering the engine using a heated wire or film element, providing real-time data to optimize fuel injection and improve combustion efficiency. MAP sensors detect the manifold absolute pressure by measuring air pressure inside the intake manifold, helping the engine control unit calculate air density and adjust fuel delivery accordingly. Both sensors are essential for accurate air-fuel mixture regulation but rely on different principles and placements within the engine system.

How MAF Sensors Work

MAF sensors measure the volume and density of incoming air by detecting changes in a heated wire's temperature as air flows past it, providing precise airflow data to the engine control unit. This real-time information helps optimize fuel injection and ignition timing for efficient combustion. Your vehicle's performance and emissions depend significantly on the accuracy of the MAF sensor's airflow measurements.

How MAP Sensors Operate

MAP sensors measure the absolute pressure within the intake manifold by detecting changes in air pressure caused by engine vacuum variations. This sensor sends voltage signals to the engine control unit (ECU), which uses the data to calculate engine load and adjust fuel injection and ignition timing. Unlike MAF sensors that measure airflow directly, MAP sensors infer air quantity indirectly through pressure changes, making them essential for optimizing combustion efficiency and emissions control.

Key Differences Between MAF and MAP Sensors

MAF (Mass Air Flow) sensors measure the exact amount of air entering the engine, providing real-time data that helps optimize fuel injection for better combustion efficiency. MAP (Manifold Absolute Pressure) sensors detect the pressure within the intake manifold, allowing the engine control unit to estimate air density and adjust fuel delivery accordingly. Your vehicle's performance and fuel economy depend on the accurate data from these sensors, with MAF offering direct airflow measurement and MAP relying on pressure-based calculations.

Advantages of MAF Sensors

MAF sensors provide precise measurement of the actual amount of air entering the engine, resulting in accurate fuel delivery and improved engine performance. They adapt better to varying engine conditions compared to MAP sensors, enhancing fuel efficiency and reducing emissions. Their direct airflow measurement helps optimize combustion, leading to smoother operation and better throttle response.

Advantages of MAP Sensors

MAP sensors offer advantages such as improved performance in forced induction engines by directly measuring manifold pressure, leading to more accurate air-fuel mixture adjustments. They tend to be more compact, cost-effective, and less susceptible to dirt and oil contamination compared to MAF sensors. Additionally, MAP sensors provide better reliability in harsh environments and can enhance fuel efficiency by delivering precise engine load information.

Applications: When to Use MAF vs MAP Sensors

MAF sensors are ideal for naturally aspirated engines where precise measurement of incoming air is needed to optimize fuel injection and maintain efficient combustion. MAP sensors perform better in forced induction engines, such as turbocharged or supercharged setups, by monitoring manifold pressure to adjust fuel delivery and ignition timing under varying boost conditions. Choosing between MAF and MAP sensors depends on the engine design, with MAF preferred for steady airflow measurement and MAP favored for dynamic pressure changes.

Common Symptoms of Sensor Failure

Common symptoms of MAF sensor failure include rough idling, poor fuel economy, and engine hesitation during acceleration. MAP sensor failure often leads to engine stalling, reduced power, and increased emissions due to incorrect air pressure readings. Monitoring these signs helps you diagnose and address sensor issues promptly, ensuring optimal engine performance.

Diagnosing MAF and MAP Sensor Issues

Diagnosing MAF sensor issues often involves checking for symptoms such as rough idling, poor fuel economy, and engine hesitation, using tools like an OBD-II scanner to identify trouble codes related to airflow measurement. MAP sensor problems are typically diagnosed by monitoring engine performance faults like stalling, hesitation, and increased emissions, with technicians analyzing sensor voltage readings and vacuum pressure to pinpoint faults. Accurate detection requires comparing sensor output against manufacturer specifications and conducting physical inspections for dirt, damage, or disconnections in both MAF and MAP sensors.

Conclusion: Choosing the Right Sensor for Your Vehicle

MAF sensors measure the actual air volume entering the engine, providing precise data for fuel injection adjustments, while MAP sensors monitor intake manifold pressure to estimate air flow indirectly. Your vehicle's specific engine management system and driving conditions determine which sensor delivers optimal performance and fuel efficiency. Selecting the right sensor ensures accurate air measurement, leading to improved engine response and reduced emissions.

MAF sensor vs MAP sensor Infographic

electrown.com

electrown.com