Harmonic drives offer high precision and zero backlash, making them ideal for applications requiring fine positioning and smooth motion control, whereas planetary gears provide higher torque capacity and durability suited for heavy-duty electronic control systems. Discover how choosing the right gear can optimize your device's performance by exploring the detailed comparison in this article.

Table of Comparison

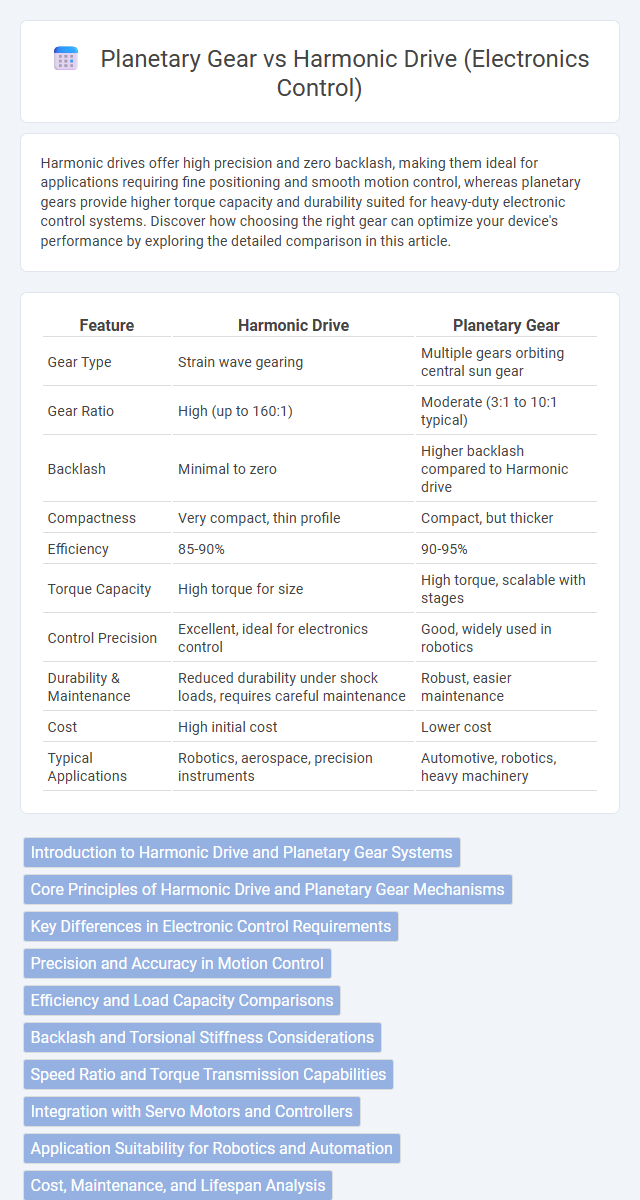

| Feature | Harmonic Drive | Planetary Gear |

|---|---|---|

| Gear Type | Strain wave gearing | Multiple gears orbiting central sun gear |

| Gear Ratio | High (up to 160:1) | Moderate (3:1 to 10:1 typical) |

| Backlash | Minimal to zero | Higher backlash compared to Harmonic drive |

| Compactness | Very compact, thin profile | Compact, but thicker |

| Efficiency | 85-90% | 90-95% |

| Torque Capacity | High torque for size | High torque, scalable with stages |

| Control Precision | Excellent, ideal for electronics control | Good, widely used in robotics |

| Durability & Maintenance | Reduced durability under shock loads, requires careful maintenance | Robust, easier maintenance |

| Cost | High initial cost | Lower cost |

| Typical Applications | Robotics, aerospace, precision instruments | Automotive, robotics, heavy machinery |

Introduction to Harmonic Drive and Planetary Gear Systems

Harmonic drive and planetary gear systems serve distinct roles in electronics control, with harmonic drives offering zero backlash, high precision, and compact size ideal for robotics and aerospace applications. Planetary gear systems feature multiple gears distributing loads evenly, providing high torque density and durability commonly utilized in industrial machinery and electric vehicles. Understanding your application's precision and torque requirements helps choose between these advanced gearing solutions.

Core Principles of Harmonic Drive and Planetary Gear Mechanisms

Harmonic drive mechanisms operate based on the elastic deformation of a flexible spline that meshes with a circular spline, providing high precision and zero backlash ideal for electronics control systems requiring smooth, accurate motion. Planetary gear systems consist of a central sun gear, multiple planet gears, and a ring gear, distributing torque evenly and offering high torque density with compact size, suitable for high load applications. Your choice between harmonic drive and planetary gear depends on the need for precision versus torque capacity in electronic control performance.

Key Differences in Electronic Control Requirements

Harmonic drives require precise electronic control to manage their elastic deformation and maintain high positional accuracy, demanding advanced sensor feedback and adaptive control algorithms. Planetary gears, featuring rigid, multi-gear arrangements, rely on established electronic control systems focused on torque distribution and speed regulation with less emphasis on elasticity compensation. The key difference lies in harmonic drives needing more sophisticated electronics for dynamic stiffness control, while planetary gear systems emphasize robust, high-torque motor control and simplified feedback mechanisms.

Precision and Accuracy in Motion Control

Harmonic drives offer superior precision and accuracy in motion control due to their near-zero backlash and high torsional stiffness, making them ideal for applications requiring fine positioning. Planetary gears, while robust and capable of high torque transmission, typically exhibit more backlash, which can reduce control accuracy in sensitive electronic systems. Your choice should prioritize harmonic drives when precise, repeatable motion is critical to performance and control reliability.

Efficiency and Load Capacity Comparisons

Harmonic drives typically exhibit higher efficiency, often exceeding 85%, due to their low friction and precise gear engagement, which makes them suitable for high-precision electronic control systems. Planetary gears, while slightly less efficient around 75-85%, excel in load capacity and durability, handling higher torque loads thanks to their multiple load-sharing gear paths. Your choice between harmonic drive and planetary gear should consider the trade-off between efficiency and load capacity based on the specific demands of your application.

Backlash and Torsional Stiffness Considerations

Harmonic drives offer near-zero backlash and exceptionally high torsional stiffness, making them ideal for precision electronics control applications requiring tight positional accuracy. Planetary gears typically exhibit higher backlash and lower torsional stiffness but provide greater load capacity and efficiency in dynamic systems. Your choice depends on whether precision or torque capacity is the priority, with harmonic drives preferred in high-precision, low backlash scenarios.

Speed Ratio and Torque Transmission Capabilities

Harmonic drives offer high speed ratios typically ranging from 30:1 to 320:1, allowing precise motion control with minimal backlash, making them ideal for robotics and aerospace applications. Planetary gears generally provide lower speed ratios, commonly between 3:1 and 10:1, but excel in torque transmission by evenly distributing load across multiple planet gears, ensuring high torque capacity and durability in industrial electronics control systems. The choice between harmonic drive and planetary gear depends on whether high precision with moderate torque or robust torque handling with lower speed ratio is prioritized.

Integration with Servo Motors and Controllers

Harmonic drives offer high precision and zero backlash, enabling superior integration with servo motors and electronic controllers for applications requiring exact positioning and smooth motion control. Planetary gears provide high torque density and durability but may introduce backlash, which can be compensated through advanced servo control algorithms to maintain accurate feedback and performance. Both gear systems require compatible servo controllers that support feedback loops, but harmonic drives typically demand finer resolution encoders to fully leverage their precision capabilities in electronic control systems.

Application Suitability for Robotics and Automation

Harmonic drives excel in robotics and automation applications demanding high precision, compact size, and zero backlash, enabling smooth and accurate motion control for robotic arms and CNC machines. Planetary gears offer high torque capacity and durability, making them ideal for heavy-load automation systems and industrial robots requiring robust performance under continuous operation. The selection between harmonic drives and planetary gears depends on the specific robotic application, balancing precision needs against torque and operational longevity.

Cost, Maintenance, and Lifespan Analysis

Harmonic drives typically have higher initial costs compared to planetary gears due to their precision manufacturing and unique flexspline design. Maintenance for harmonic drives tends to be lower because of fewer moving parts, but their lifespan can be limited by the flexspline fatigue, often requiring replacement after extended use. Planetary gears, while generally more affordable and robust with a longer operational lifespan, may demand more frequent lubrication and inspection to sustain performance in demanding electronics control applications.

Harmonic drive vs Planetary gear (electronics control) Infographic

electrown.com

electrown.com