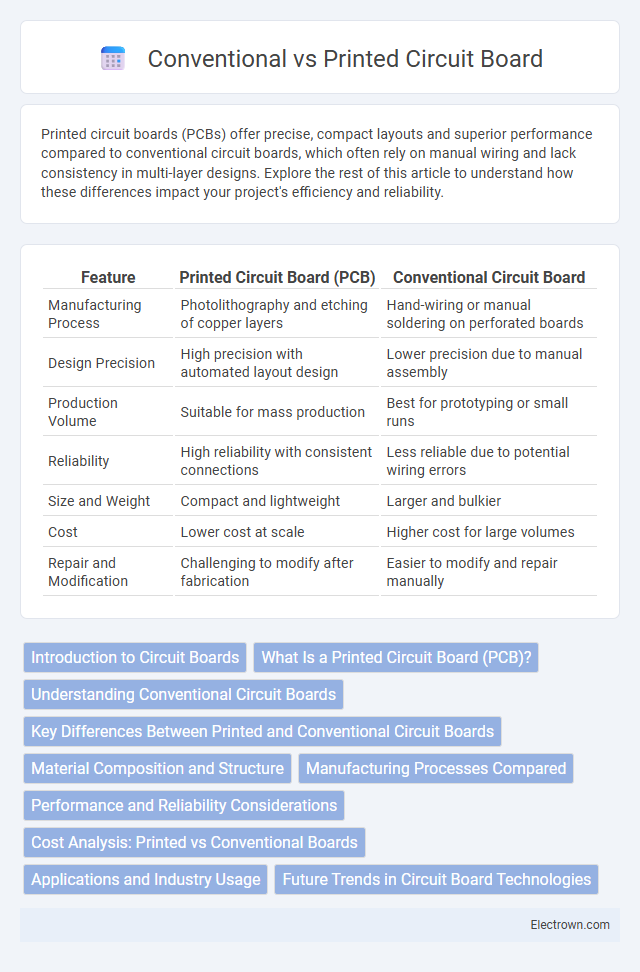

Printed circuit boards (PCBs) offer precise, compact layouts and superior performance compared to conventional circuit boards, which often rely on manual wiring and lack consistency in multi-layer designs. Explore the rest of this article to understand how these differences impact your project's efficiency and reliability.

Table of Comparison

| Feature | Printed Circuit Board (PCB) | Conventional Circuit Board |

|---|---|---|

| Manufacturing Process | Photolithography and etching of copper layers | Hand-wiring or manual soldering on perforated boards |

| Design Precision | High precision with automated layout design | Lower precision due to manual assembly |

| Production Volume | Suitable for mass production | Best for prototyping or small runs |

| Reliability | High reliability with consistent connections | Less reliable due to potential wiring errors |

| Size and Weight | Compact and lightweight | Larger and bulkier |

| Cost | Lower cost at scale | Higher cost for large volumes |

| Repair and Modification | Challenging to modify after fabrication | Easier to modify and repair manually |

Introduction to Circuit Boards

Circuit boards serve as the foundation for electronic devices, facilitating the connection and support of various components. Printed Circuit Boards (PCBs) offer precise, automated fabrication with intricate pathways, enhancing reliability and reducing size compared to Conventional Circuit Boards, which rely on manually wired connections. Understanding these differences helps you choose the appropriate technology for efficient, scalable electronic design and manufacturing.

What Is a Printed Circuit Board (PCB)?

A Printed Circuit Board (PCB) is a flat board made of insulating material, typically fiberglass, with conductive pathways etched from copper sheets laminated onto its surface. PCBs mechanically support and electrically connect electronic components using these copper traces, pads, and other features stamped or printed onto the board. Unlike conventional wiring methods, PCBs enable compact, reliable, and mass-producible electronic circuits essential for modern devices.

Understanding Conventional Circuit Boards

Conventional circuit boards consist of a flat, rigid substrate typically made from fiberglass or composite epoxy materials, where electrical components are manually soldered onto pre-etched copper pathways. These boards rely on through-hole technology, which offers strong mechanical bonds and durability for heavy or high-stress applications but can limit design complexity and miniaturization. Understanding conventional circuit boards highlights their cost-effectiveness and ease of prototyping, making them suitable for lower-volume or simpler electronic devices.

Key Differences Between Printed and Conventional Circuit Boards

Printed circuit boards (PCBs) differ from conventional circuit boards primarily in manufacturing techniques and material usage, with PCBs using laminated substrates like FR-4 and photolithographic etching, while conventional boards rely on hand wiring or point-to-point construction. PCBs offer higher assembly precision, compact design, and improved electrical performance compared to conventional circuit boards that feature bulkier layouts and increased susceptibility to wiring errors. Automated production of PCBs enables mass manufacturing scalability and consistent quality, distinguishing them significantly from the labor-intensive, less reliable conventional circuit board methods.

Material Composition and Structure

Printed circuit boards (PCBs) are composed of layered materials including a non-conductive substrate such as fiberglass-reinforced epoxy resin topped with copper foil, etched to form electrical pathways. Conventional circuit boards often use phenolic resin or paper-based laminates, which provide less durability and electrical insulation compared to the advanced fiberglass substrates in PCBs. Your choice between printed and conventional circuit boards impacts the overall structural integrity, heat resistance, and electrical performance of electronic devices.

Manufacturing Processes Compared

Printed circuit boards (PCBs) are fabricated through automated processes such as photolithography, etching, and layering, enabling precise and repeatable production of complex electronic circuits. Conventional circuit boards often involve manual assembly techniques including hand wiring and point-to-point soldering, which can increase manufacturing time and variability. Understanding these manufacturing differences helps you choose the most efficient and cost-effective solution for your electronic device needs.

Performance and Reliability Considerations

Printed circuit boards (PCBs) offer superior signal integrity and consistent electrical performance compared to conventional circuit boards, reducing noise and electromagnetic interference for high-frequency applications. Their layered design enhances thermal management and mechanical stability, directly improving reliability under stress and prolonged use. Selecting a PCB for Your project ensures enhanced durability and precise performance, critical for advanced electronic systems.

Cost Analysis: Printed vs Conventional Boards

Printed circuit boards (PCBs) typically offer lower manufacturing costs compared to conventional circuit boards due to automated production processes and material efficiency. Conventional boards often involve manual assembly and bulkier components, driving up labor and material expenses. Your choice impacts total expenses, with PCBs providing cost-effective scalability for complex electronics.

Applications and Industry Usage

Printed Circuit Boards (PCBs) dominate electronics manufacturing across industries like consumer electronics, automotive, aerospace, and healthcare due to their compact design and reliability. Conventional circuit boards, often used in simple or low-volume applications such as prototyping and educational projects, typically lack the intricate layering and automation found in PCBs. Your choice between these types depends on application complexity, production scale, and performance requirements within industries demanding precision and durability.

Future Trends in Circuit Board Technologies

Future trends in circuit board technologies emphasize the shift towards flexible printed circuit boards (FPCBs) and advanced materials like polyimide and liquid crystal polymer that enhance durability and miniaturization. Emerging additive manufacturing techniques, such as 3D printing of conductive inks, enable rapid prototyping and complex multi-layer designs for printed circuit boards (PCBs). Integration of embedded sensors and IoT components on conventional circuit boards promotes smarter, more efficient electronics across automotive, aerospace, and wearable device industries.

Printed vs Conventional Circuit Board Infographic

electrown.com

electrown.com