Microfluidic chips manipulate fluids at the microscale, enabling precise control, reduced reagent consumption, and faster reactions compared to macrofluidic chips which handle larger volumes but with less precision. Explore the full article to understand how choosing between microfluidic and macrofluidic chips can optimize your specific application.

Table of Comparison

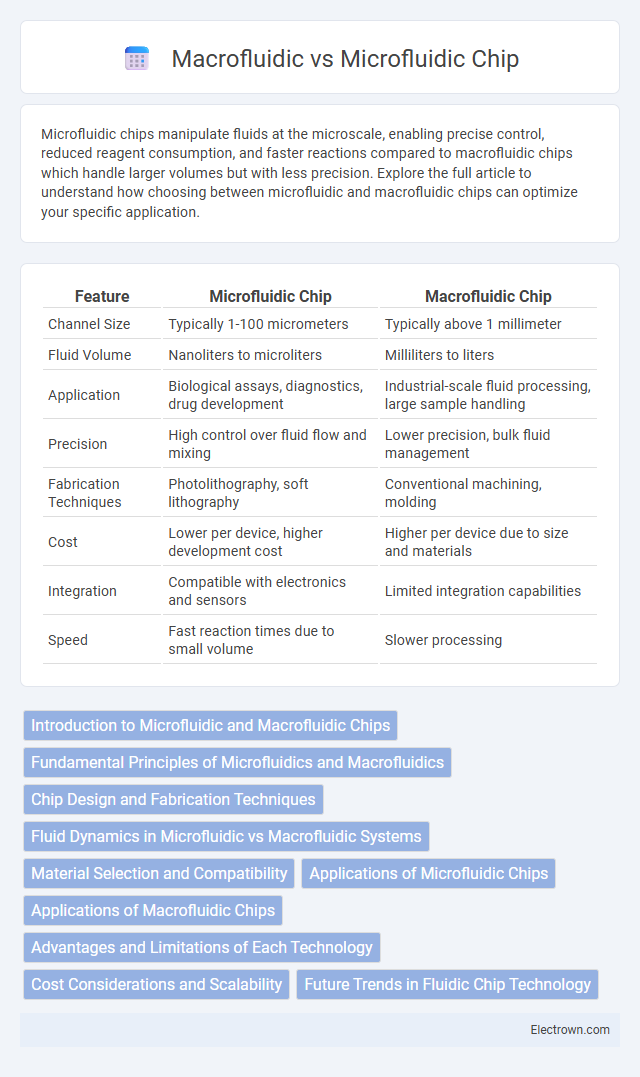

| Feature | Microfluidic Chip | Macrofluidic Chip |

|---|---|---|

| Channel Size | Typically 1-100 micrometers | Typically above 1 millimeter |

| Fluid Volume | Nanoliters to microliters | Milliliters to liters |

| Application | Biological assays, diagnostics, drug development | Industrial-scale fluid processing, large sample handling |

| Precision | High control over fluid flow and mixing | Lower precision, bulk fluid management |

| Fabrication Techniques | Photolithography, soft lithography | Conventional machining, molding |

| Cost | Lower per device, higher development cost | Higher per device due to size and materials |

| Integration | Compatible with electronics and sensors | Limited integration capabilities |

| Speed | Fast reaction times due to small volume | Slower processing |

Introduction to Microfluidic and Macrofluidic Chips

Microfluidic chips manipulate fluids at the microliter to picoliter scale within channels typically under 100 micrometers wide, enabling precise control for applications such as medical diagnostics and biochemical assays. Macrofluidic chips handle larger liquid volumes through millimeter-sized channels, suited for industrial processes and large-scale fluid management. Both technologies utilize microfabrication techniques but differ significantly in scale, fluid dynamics, and scope of application.

Fundamental Principles of Microfluidics and Macrofluidics

Microfluidic chips operate based on the manipulation of fluids at the micrometer scale, relying on laminar flow, surface tension, and capillary forces to precisely control fluid behavior in channels typically less than 100 micrometers wide. In contrast, macrofluidic chips handle fluids at a much larger scale, where turbulent flow and gravitational forces dominate, making fluid dynamics governed by Navier-Stokes equations more complex and less predictable. Understanding these fundamental principles enables you to select the appropriate chip type for applications requiring high precision, such as biochemical assays in microfluidics or bulk fluid processing in macrofluidics.

Chip Design and Fabrication Techniques

Microfluidic chips feature intricate networks of channels measuring 10 to 100 micrometers, designed using photolithography and soft lithography techniques primarily with PDMS or glass substrates. Macrofluidic chips, by contrast, incorporate larger channels often fabricated through milling, laser cutting, or 3D printing methods, typically utilizing rigid plastics or metals. The design complexity and fabrication precision are significantly higher in microfluidics to facilitate controlled fluid manipulation at microscale, whereas macrofluidics focus on handling larger volumes with simpler channel architectures.

Fluid Dynamics in Microfluidic vs Macrofluidic Systems

Microfluidic systems manipulate fluids at the microliter to picoliter scale, enabling precise control of laminar flow and minimal turbulence due to low Reynolds numbers. Macrofluidic systems handle larger volumes with higher Reynolds numbers, resulting in turbulent flow and less predictable fluid behavior. Understanding these differences helps optimize your application by selecting the appropriate chip type for accurate fluid dynamics control and efficiency.

Material Selection and Compatibility

Material selection for microfluidic chips typically involves polymers like PDMS and cyclic olefin copolymers due to their optical transparency, biocompatibility, and ease of fabrication, whereas macrofluidic chips often utilize glass or metals to withstand higher pressures and chemical exposure. Compatibility considerations in microfluidic systems prioritize minimal absorption and chemical inertness to preserve sample integrity, while macrofluidic chips require materials resistant to corrosion and mechanical stress for robust long-term operation. Selecting materials that match fluid properties and application requirements is critical for optimizing device performance across both microfluidic and macrofluidic platforms.

Applications of Microfluidic Chips

Microfluidic chips are extensively applied in biomedical diagnostics, enabling precise manipulation of small fluid volumes for point-of-care testing and disease detection. These chips facilitate drug development through high-throughput screening and personalized medicine by simulating organ-on-chip models. Applications also include environmental monitoring and biochemical analysis, benefiting from the enhanced sensitivity and reduced reagent consumption compared to macrofluidic systems.

Applications of Macrofluidic Chips

Macrofluidic chips are widely utilized in applications requiring the manipulation of larger fluid volumes, such as industrial chemical processing, environmental monitoring, and biomedical sample preparation. Their capability to handle milliliter to liter-scale fluids enables tasks like large-scale cell culture, drug manufacturing, and water quality analysis. Your processes benefit from enhanced throughput and scalability when employing macrofluidic chips for these extensive fluid handling applications.

Advantages and Limitations of Each Technology

Microfluidic chips offer precise control over small fluid volumes, enabling high-throughput screening and reduced reagent consumption, but they face challenges in scalability and complex sample handling. Macrofluidic chips handle larger fluid volumes suitable for industrial-scale processes and robust operations, though they lack the fine control and sensitivity of microfluidic systems. Each technology balances trade-offs between sensitivity, throughput, sample volume, and application specificity.

Cost Considerations and Scalability

Microfluidic chips offer lower material costs and reduced reagent consumption compared to macrofluidic chips, making them cost-effective for small-scale and high-throughput applications. Scalability challenges arise with microfluidic systems due to complex fabrication processes and the precision required for channel designs, whereas macrofluidic chips are more straightforward to scale for larger volumes but incur higher fluid and material costs. Economies of scale favor macrofluidic chips in industrial settings, while microfluidic chips excel in research and diagnostic environments with limited sample volumes.

Future Trends in Fluidic Chip Technology

Future trends in fluidic chip technology emphasize the integration of microfluidic and macrofluidic systems to enhance scalability and precision in biomedical applications. Advances in materials such as flexible polymers and biocompatible substrates enable more robust, wearable fluidic devices with improved fluid control and real-time monitoring capabilities. The incorporation of machine learning algorithms for fluid dynamic optimization and automated diagnostics is set to revolutionize personalized medicine and high-throughput screening platforms.

Microfluidic vs Macrofluidic Chip Infographic

electrown.com

electrown.com