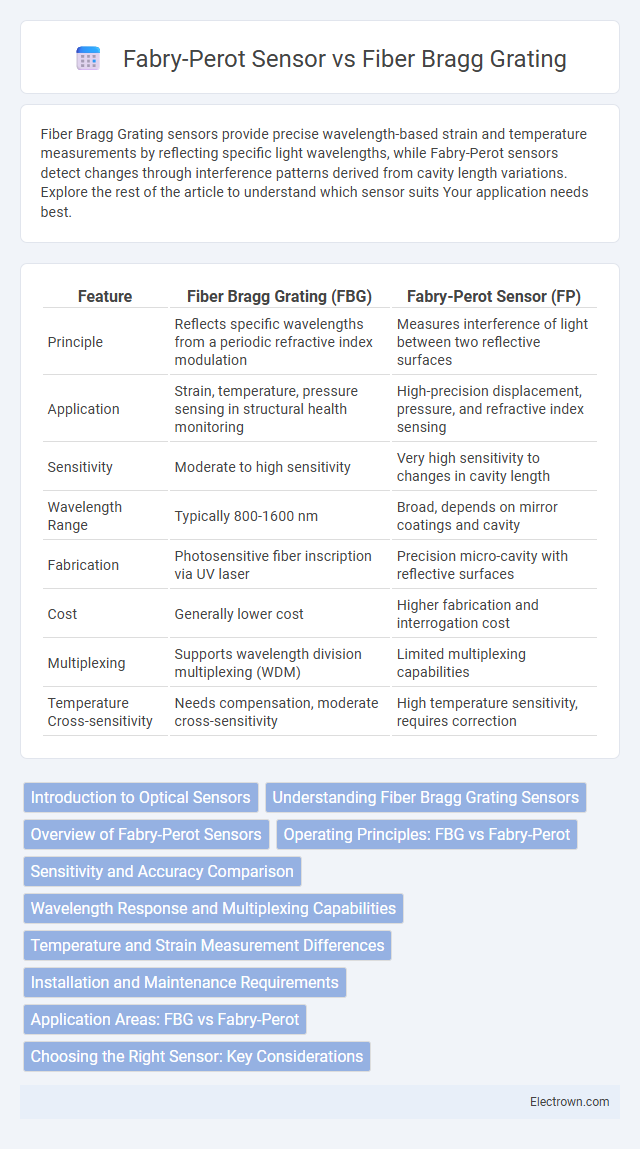

Fiber Bragg Grating sensors provide precise wavelength-based strain and temperature measurements by reflecting specific light wavelengths, while Fabry-Perot sensors detect changes through interference patterns derived from cavity length variations. Explore the rest of the article to understand which sensor suits Your application needs best.

Table of Comparison

| Feature | Fiber Bragg Grating (FBG) | Fabry-Perot Sensor (FP) |

|---|---|---|

| Principle | Reflects specific wavelengths from a periodic refractive index modulation | Measures interference of light between two reflective surfaces |

| Application | Strain, temperature, pressure sensing in structural health monitoring | High-precision displacement, pressure, and refractive index sensing |

| Sensitivity | Moderate to high sensitivity | Very high sensitivity to changes in cavity length |

| Wavelength Range | Typically 800-1600 nm | Broad, depends on mirror coatings and cavity |

| Fabrication | Photosensitive fiber inscription via UV laser | Precision micro-cavity with reflective surfaces |

| Cost | Generally lower cost | Higher fabrication and interrogation cost |

| Multiplexing | Supports wavelength division multiplexing (WDM) | Limited multiplexing capabilities |

| Temperature Cross-sensitivity | Needs compensation, moderate cross-sensitivity | High temperature sensitivity, requires correction |

Introduction to Optical Sensors

Optical sensors such as Fiber Bragg Grating (FBG) and Fabry-Perot sensors exploit light modulation for precise measurement of physical parameters including strain, temperature, and pressure. FBG sensors utilize wavelength shifts caused by changes in the grating period within an optical fiber, providing high sensitivity and multiplexing capabilities. Fabry-Perot sensors operate on interference patterns generated between two reflective surfaces, enabling accurate detection of minute displacements and environmental variations.

Understanding Fiber Bragg Grating Sensors

Fiber Bragg Grating (FBG) sensors utilize periodic variations in the refractive index within an optical fiber to reflect specific wavelengths of light, enabling precise strain and temperature measurements. These sensors are highly sensitive, immune to electromagnetic interference, and capable of multiplexing, making them ideal for structural health monitoring and telecommunications. In contrast, Fabry-Perot sensors rely on cavity interference patterns for sensing but generally lack the multiplexing capabilities and robustness of FBG sensors in complex environments.

Overview of Fabry-Perot Sensors

Fabry-Perot sensors utilize an optical cavity formed by two parallel reflective surfaces to measure changes in physical parameters such as pressure, temperature, and strain with high sensitivity. The interference pattern generated by multiple reflections inside the cavity shifts in response to external stimuli, allowing precise detection of variations. These sensors are widely used in telecommunications, structural health monitoring, and biomedical applications due to their compact size and high resolution.

Operating Principles: FBG vs Fabry-Perot

Fiber Bragg Grating (FBG) sensors operate by reflecting specific wavelengths of light based on periodic variations in the fiber's refractive index, allowing strain or temperature changes to shift the reflected wavelength. Fabry-Perot sensors use an optical cavity formed by two parallel reflectors, where interference patterns generated by multiple reflections within the cavity vary with external perturbations like pressure or displacement. FBG sensors provide wavelength-encoded signals with high multiplexing capability, while Fabry-Perot sensors offer high sensitivity through optical interference within the cavity length.

Sensitivity and Accuracy Comparison

Fiber Bragg Grating (FBG) sensors exhibit high sensitivity to strain and temperature changes due to their precise wavelength shift detection, enabling accurate measurements in various applications. Fabry-Perot sensors offer superior accuracy in displacement and pressure sensing through interference pattern analysis, with sensitivity largely dependent on cavity length and refractive index variations. While FBG sensors provide robust multi-parameter monitoring with low cross-sensitivity, Fabry-Perot sensors excel in ultra-high-resolution measurements but may require more complex signal processing for optimal accuracy.

Wavelength Response and Multiplexing Capabilities

Fiber Bragg Grating (FBG) sensors exhibit a narrowband wavelength response that shifts linearly with strain or temperature, enabling precise and stable measurements ideal for multiplexing through wavelength division. Fabry-Perot sensors, characterized by their broadband spectrum and interference-based wavelength response, provide high sensitivity but face challenges in dense multiplexing due to overlapping spectral signatures. FBG arrays allow for multiple sensors on a single fiber with minimal crosstalk, whereas Fabry-Perot sensors typically require more complex demodulation techniques to achieve comparable multiplexing scalability.

Temperature and Strain Measurement Differences

Fiber Bragg Grating (FBG) sensors use periodic variations in the fiber core to reflect specific wavelengths, enabling precise measurement of both temperature and strain with high sensitivity and spatial resolution. Fabry-Perot sensors rely on interference patterns generated within a cavity, offering superior accuracy in temperature sensing but often requiring compensation techniques to distinguish strain effects. Your choice depends on whether you need multiplexing capabilities and distributed sensing (FBG) or high-resolution local measurements with stable temperature characterization (Fabry-Perot).

Installation and Maintenance Requirements

Fiber Bragg Grating (FBG) sensors require precise alignment during installation to ensure accurate wavelength reflection, typically necessitating skilled technicians and specialized equipment. Maintenance of FBG sensors is minimal due to their passive nature and resistance to electromagnetic interference, allowing for long-term stability without frequent recalibration. Fabry-Perot sensors often involve more complex installation with critical cavity spacing adjustments and may require periodic maintenance to address sensitivity drift and ensure consistent signal quality.

Application Areas: FBG vs Fabry-Perot

Fiber Bragg Grating (FBG) sensors excel in structural health monitoring for aerospace, civil engineering, and energy industries due to their high sensitivity to strain and temperature changes. Fabry-Perot sensors are preferred in precision measurement applications such as biomedical sensing and environmental monitoring, where fine displacement or pressure variations need to be detected. Your choice between FBG and Fabry-Perot sensors depends on the specific application requirements involving sensitivity, measurement range, and environmental conditions.

Choosing the Right Sensor: Key Considerations

Selecting the right sensor between Fiber Bragg Grating (FBG) and Fabry-Perot sensors depends on factors like sensitivity, measurement range, and environmental conditions. FBG sensors offer high multiplexing capability and immunity to electromagnetic interference, making them ideal for structural health monitoring and temperature sensing. Fabry-Perot sensors provide superior resolution and accuracy in strain and pressure measurements but may require more complex signal processing and stabilization techniques.

Fiber Bragg Grating vs Fabry-Perot Sensor Infographic

electrown.com

electrown.com