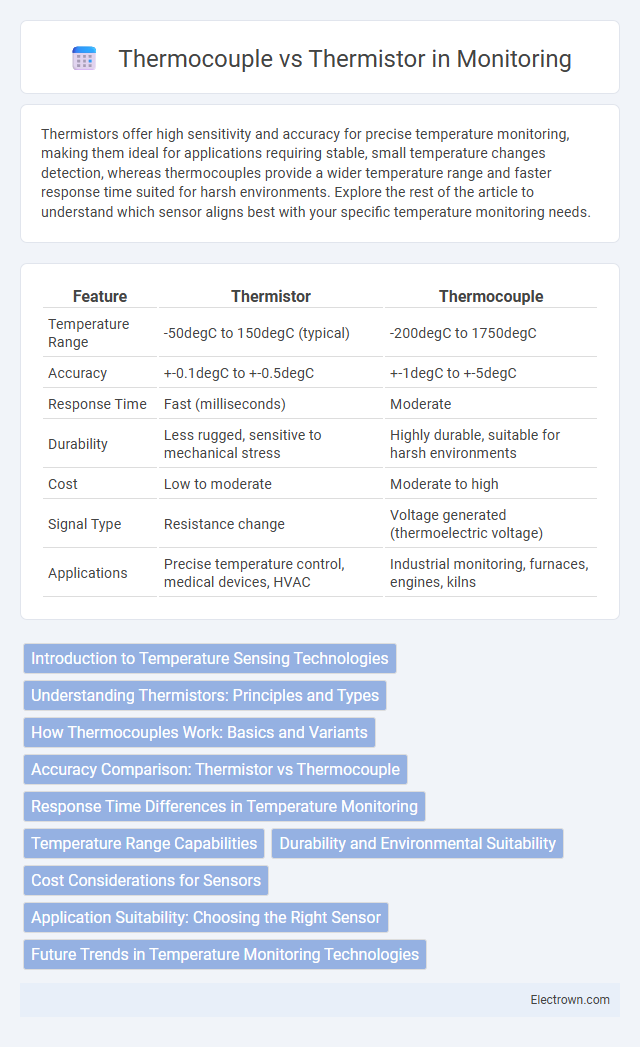

Thermistors offer high sensitivity and accuracy for precise temperature monitoring, making them ideal for applications requiring stable, small temperature changes detection, whereas thermocouples provide a wider temperature range and faster response time suited for harsh environments. Explore the rest of the article to understand which sensor aligns best with your specific temperature monitoring needs.

Table of Comparison

| Feature | Thermistor | Thermocouple |

|---|---|---|

| Temperature Range | -50degC to 150degC (typical) | -200degC to 1750degC |

| Accuracy | +-0.1degC to +-0.5degC | +-1degC to +-5degC |

| Response Time | Fast (milliseconds) | Moderate |

| Durability | Less rugged, sensitive to mechanical stress | Highly durable, suitable for harsh environments |

| Cost | Low to moderate | Moderate to high |

| Signal Type | Resistance change | Voltage generated (thermoelectric voltage) |

| Applications | Precise temperature control, medical devices, HVAC | Industrial monitoring, furnaces, engines, kilns |

Introduction to Temperature Sensing Technologies

Thermistors and thermocouples are two widely used temperature sensing technologies with distinct characteristics and applications. Thermistors offer high sensitivity and accuracy within a limited temperature range, making them ideal for precise monitoring in HVAC systems and medical devices. Thermocouples provide a broad temperature range and rapid response times, suitable for industrial processes and high-temperature environments where durability is critical for your monitoring needs.

Understanding Thermistors: Principles and Types

Thermistors operate based on the principle that their electrical resistance varies significantly with temperature changes, making them highly sensitive for precise temperature monitoring. There are two main types: Negative Temperature Coefficient (NTC) thermistors, which decrease in resistance as temperature rises, and Positive Temperature Coefficient (PTC) thermistors, which increase in resistance with rising temperature. Your choice between thermistors and thermocouples depends on factors such as required accuracy, temperature range, and response time for effective monitoring applications.

How Thermocouples Work: Basics and Variants

Thermocouples operate by measuring the voltage generated when two dissimilar metals are joined at one end, producing a temperature-dependent electromotive force (EMF). Common types include Type K (Nickel-Chromium/Nickel-Alumel) for general use, Type J (Iron/Constantan) for lower temperatures, and Type T (Copper/Constantan) for precise measurements in cryogenic environments. Your choice of thermocouple variant depends on the temperature range, accuracy requirements, and environmental conditions of your monitoring application.

Accuracy Comparison: Thermistor vs Thermocouple

Thermistors provide higher accuracy within a narrow temperature range, often with precision up to +-0.1degC, making them ideal for applications requiring detailed temperature monitoring. Thermocouples offer broader temperature measurement capabilities but typically with lower accuracy, around +-1 to +-2degC, suitable for industrial environments with extreme temperature variations. Choosing between a thermistor and thermocouple depends on the specific accuracy requirements and temperature range of the monitoring application.

Response Time Differences in Temperature Monitoring

Thermistors generally offer faster response times in temperature monitoring due to their smaller size and higher sensitivity compared to thermocouples. Thermocouples, while more durable and capable of measuring wider temperature ranges, typically have slower response times influenced by their metal junction construction. Understanding these differences can help you choose the most effective sensor for applications requiring rapid temperature detection.

Temperature Range Capabilities

Thermistors offer precise temperature measurements within a limited range, typically between -55degC and 150degC, making them ideal for applications requiring high accuracy in moderate conditions. Thermocouples can measure extreme temperatures from -200degC up to 2300degC depending on the type, providing versatility for harsh or industrial environments. Your choice between a thermistor and thermocouple depends on the required temperature range and the specific monitoring conditions.

Durability and Environmental Suitability

Thermistors offer high sensitivity and stability but generally have lower durability compared to thermocouples, which withstand extreme temperatures and harsh environments better. Thermocouples are ideal for industrial settings with fluctuating or high-temperature conditions due to their rugged construction and wide temperature range tolerance. Your choice depends on the environmental conditions and longevity requirements of your monitoring application.

Cost Considerations for Sensors

Thermistors generally offer a lower cost solution for temperature monitoring due to their simple construction and ease of manufacturing, making them ideal for budget-sensitive applications. Thermocouples, while typically more expensive, provide a broader temperature range and greater durability in harsh environments, which can justify the higher initial investment. Your choice between thermistor and thermocouple sensors should balance upfront cost against performance requirements and long-term reliability.

Application Suitability: Choosing the Right Sensor

Thermistors offer high sensitivity and accuracy in a narrow temperature range, making them ideal for medical devices and HVAC systems where precise temperature control is critical. Thermocouples excel in extreme temperature environments, such as industrial furnaces and jet engines, due to their wide temperature range and durability. Your choice between thermistor and thermocouple depends on application-specific factors like temperature range, response time, and environmental conditions.

Future Trends in Temperature Monitoring Technologies

Thermistors and thermocouples are key components in temperature monitoring, with thermocouples excelling in high-temperature applications and thermistors offering superior precision at moderate temperatures. Future trends highlight the integration of IoT and wireless communication to enable real-time data analysis and predictive maintenance. Your choice between these sensors will increasingly depend on the need for smart, interconnected temperature monitoring solutions in industrial and environmental settings.

Thermistor vs Thermocouple in Monitoring Infographic

electrown.com

electrown.com