Conductive polymers offer flexibility, lightweight properties, and easier processability compared to traditional metal electrodes, making them ideal for wearable electronics and flexible devices. Explore the rest of the article to understand how your choice between conductive polymer and metal electrodes can impact device performance and application suitability.

Table of Comparison

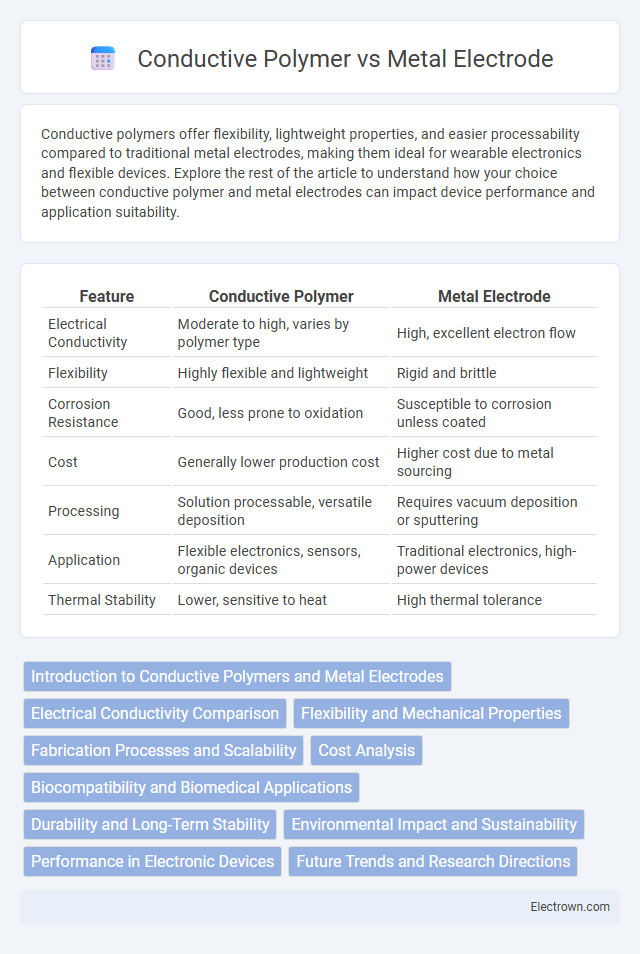

| Feature | Conductive Polymer | Metal Electrode |

|---|---|---|

| Electrical Conductivity | Moderate to high, varies by polymer type | High, excellent electron flow |

| Flexibility | Highly flexible and lightweight | Rigid and brittle |

| Corrosion Resistance | Good, less prone to oxidation | Susceptible to corrosion unless coated |

| Cost | Generally lower production cost | Higher cost due to metal sourcing |

| Processing | Solution processable, versatile deposition | Requires vacuum deposition or sputtering |

| Application | Flexible electronics, sensors, organic devices | Traditional electronics, high-power devices |

| Thermal Stability | Lower, sensitive to heat | High thermal tolerance |

Introduction to Conductive Polymers and Metal Electrodes

Conductive polymers are organic materials that combine the electrical properties of metals with the mechanical flexibility of plastics, making them ideal for flexible electronics and wearable devices. Metal electrodes, typically composed of materials like gold, silver, or copper, offer excellent conductivity and stability but lack the adaptability and lightweight characteristics of conductive polymers. The choice between conductive polymers and metal electrodes depends on application requirements such as flexibility, conductivity, biocompatibility, and cost-effectiveness.

Electrical Conductivity Comparison

Conductive polymers generally exhibit lower electrical conductivity than metal electrodes, with metals like copper and silver reaching conductivities above 10^7 S/m, whereas most conductive polymers range between 10^0 to 10^5 S/m. Your choice between conductive polymer and metal electrode depends on the application's conductivity requirements, as metals provide superior electron mobility and minimal resistance for high-performance circuits. However, conductive polymers offer advantages such as flexibility, weight reduction, and tunable conductivity that can suit specific electronic devices where moderate conductivity suffices.

Flexibility and Mechanical Properties

Conductive polymers offer superior flexibility and mechanical compliance compared to metal electrodes, making them ideal for wearable and stretchable electronics. Their polymeric chains provide high elasticity and resistance to mechanical strain without cracking or degrading electrical performance. Metals, while excellent conductors, tend to be rigid and prone to fatigue or fracture under repeated bending or stretching.

Fabrication Processes and Scalability

Conductive polymers offer versatile fabrication processes such as solution casting, spin coating, and inkjet printing, enabling low-cost and flexible device manufacturing compared to traditional metal electrodes that typically require vacuum deposition or sputtering techniques. Scalability favors conductive polymers due to their compatibility with roll-to-roll processing and large-area coatings, which reduce production time and material waste. Your choice of electrode material impacts overall manufacturing efficiency, with conductive polymers providing a scalable alternative to the more rigid and resource-intensive fabrication of metal electrodes.

Cost Analysis

Conductive polymers generally offer lower material and manufacturing costs compared to metal electrodes due to their solution processability and compatibility with flexible substrates. Metal electrodes, while often providing superior conductivity and durability, require expensive vacuum deposition and etching processes that increase overall production expenses. The cost-effectiveness of conductive polymers makes them attractive for large-area, flexible electronic applications despite potential trade-offs in electrical performance.

Biocompatibility and Biomedical Applications

Conductive polymers exhibit superior biocompatibility compared to metal electrodes due to their flexibility, tunable conductivity, and chemical similarity to biological tissues, reducing immune response and inflammation risks in implantable devices. Metal electrodes offer excellent electrical conductivity but often cause adverse tissue reactions and corrosion, limiting their long-term use in biomedical applications like neural interfaces and biosensors. Your choice between conductive polymers and metal electrodes significantly impacts device performance and patient safety in medical diagnostics and therapeutics.

Durability and Long-Term Stability

Conductive polymers offer enhanced flexibility and corrosion resistance compared to metal electrodes, resulting in improved durability under mechanical stress and varying environmental conditions. Metal electrodes typically exhibit higher electrical conductivity but are prone to oxidation and degradation over time, reducing long-term stability in harsh environments. Advances in conductive polymer composites have significantly increased their stability, making them suitable alternatives for applications requiring long-term performance.

Environmental Impact and Sustainability

Conductive polymers offer significant environmental benefits over metal electrodes due to their lower energy consumption during production and reduced reliance on finite metal resources, resulting in less mining waste and pollution. Their biodegradability and potential for recycling support sustainability by minimizing electronic waste and enabling greener disposal methods. Choosing conductive polymer electrodes can enhance your project's eco-friendliness while reducing the overall carbon footprint associated with electrode manufacturing and disposal.

Performance in Electronic Devices

Conductive polymers offer flexibility and lightweight properties, making them ideal for wearable electronics and flexible displays, while metal electrodes provide superior conductivity and mechanical robustness essential for high-performance applications like integrated circuits. The performance of electronic devices depends on the balance between the polymer's tunable electrical characteristics and the metal's stable, low-resistance pathways. You can enhance device efficiency by selecting conductive polymers for cost-effective, adaptable designs or metal electrodes for durability and precision in demanding environments.

Future Trends and Research Directions

Emerging research in conductive polymers targets enhanced flexibility, biocompatibility, and tunable electrical properties to surpass traditional metal electrodes in wearable and implantable devices. Innovations focus on hybrid composites combining metals and conductive polymers, aiming to optimize conductivity and mechanical durability while maintaining lightweight structures. Future trends highlight scalable manufacturing techniques and ecologique materials to meet rising demands in flexible electronics and sustainable technology development.

Conductive Polymer vs Metal Electrode Infographic

electrown.com

electrown.com