The 4-20mA current loop is preferred for its noise immunity and ability to transmit signals over long distances without significant loss, while 0-10V voltage signals are simpler but more susceptible to voltage drop and interference. Understanding the differences between these two signal types will help you choose the right method for your industrial automation or sensor applications. Read on to explore the key advantages and use cases for each.

Table of Comparison

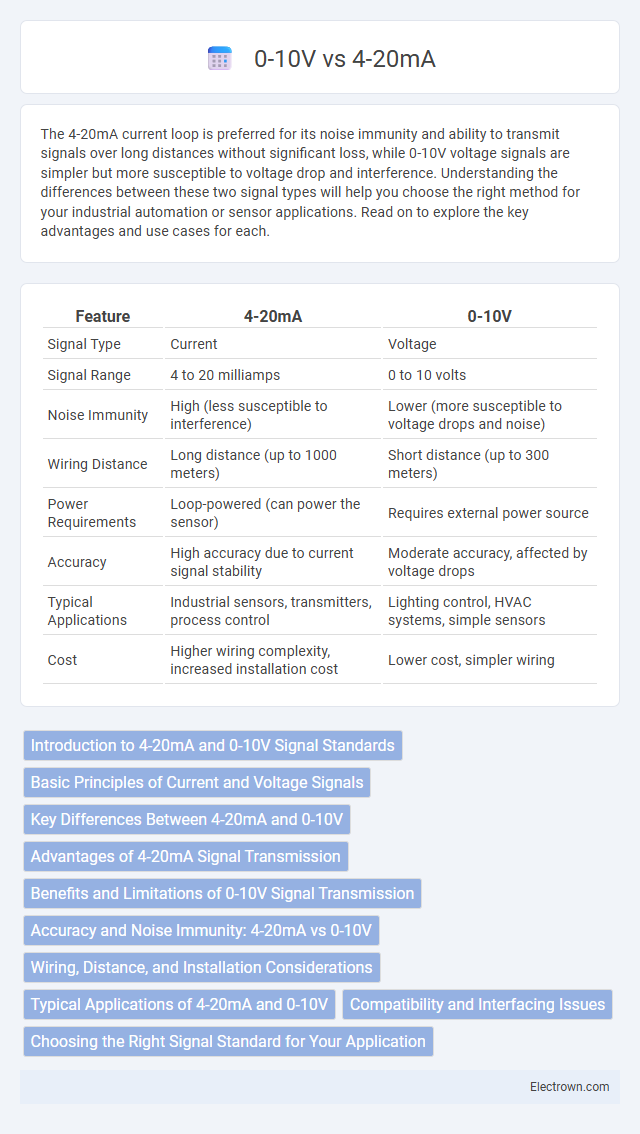

| Feature | 4-20mA | 0-10V |

|---|---|---|

| Signal Type | Current | Voltage |

| Signal Range | 4 to 20 milliamps | 0 to 10 volts |

| Noise Immunity | High (less susceptible to interference) | Lower (more susceptible to voltage drops and noise) |

| Wiring Distance | Long distance (up to 1000 meters) | Short distance (up to 300 meters) |

| Power Requirements | Loop-powered (can power the sensor) | Requires external power source |

| Accuracy | High accuracy due to current signal stability | Moderate accuracy, affected by voltage drops |

| Typical Applications | Industrial sensors, transmitters, process control | Lighting control, HVAC systems, simple sensors |

| Cost | Higher wiring complexity, increased installation cost | Lower cost, simpler wiring |

Introduction to 4-20mA and 0-10V Signal Standards

4-20mA and 0-10V are widely used analog signal standards in industrial automation for transmitting sensor data and control signals. The 4-20mA current loop provides robust noise immunity and long-distance transmission, making it ideal for harsh environments. In contrast, the 0-10V voltage signal is simpler and cost-effective but more susceptible to signal degradation over long cables.

Basic Principles of Current and Voltage Signals

4-20mA current signals maintain a consistent current flow that varies proportionally to the measured parameter, making them less susceptible to signal loss over long distances and electrical noise interference. In comparison, 0-10V voltage signals represent the measured value through variable voltage levels but can experience voltage drops and signal degradation due to resistance in transmission lines. Your choice between these signals depends on the application requirements for accuracy, distance, and noise immunity in industrial automation systems.

Key Differences Between 4-20mA and 0-10V

The 4-20mA current loop transmits signals over long distances with high noise immunity, making it ideal for industrial environments, whereas the 0-10V voltage signal is more susceptible to voltage drop and electromagnetic interference. The 4-20mA standard provides inherent fault detection since a current below 4mA indicates a wiring issue, while 0-10V cannot differentiate a device failure from a zero-level signal. Power consumption for 4-20mA devices is generally lower, facilitating easier integration with sensors and actuators compared to the higher power demand of 0-10V systems.

Advantages of 4-20mA Signal Transmission

4-20mA signal transmission offers superior noise immunity compared to 0-10V, making it ideal for long-distance industrial sensor measurements. This current loop maintains signal integrity despite voltage drops or electrical interference, ensuring reliable and accurate data for your control systems. Additionally, 4-20mA provides built-in fault detection, as signals below 4mA indicate wiring issues or device failures.

Benefits and Limitations of 0-10V Signal Transmission

0-10V signal transmission offers simple wiring and compatibility with a wide range of devices, making it suitable for controlling lighting and HVAC systems. However, it is more susceptible to electrical noise and voltage drop over long distances, which can degrade signal accuracy and reliability. Your choice should consider the environment and distance to ensure optimal performance when using 0-10V control signals.

Accuracy and Noise Immunity: 4-20mA vs 0-10V

The 4-20mA signal offers superior noise immunity compared to 0-10V, as current signals are less susceptible to voltage drops and electromagnetic interference over long distances. Accuracy in 4-20mA loops remains consistent even with wiring resistance, whereas 0-10V signals can suffer from voltage attenuation, leading to potential measurement errors. Your choice should favor 4-20mA for reliable, precise sensor data in industrial environments with high electrical noise.

Wiring, Distance, and Installation Considerations

4-20mA signals are preferred for long-distance wiring due to their robustness against electrical noise and voltage drop, enabling reliable transmission up to several hundred meters without signal degradation. In contrast, 0-10V signals are more susceptible to voltage loss and interference, limiting effective transmission distance to typically under 100 meters and requiring shielded cables or twisted pairs for noise reduction. Installation considerations for 4-20mA include simpler wiring with two-wire loops and intrinsic safety suitability, whereas 0-10V requires separate power lines, careful grounding, and is generally better suited for shorter distances and less electrically noisy environments.

Typical Applications of 4-20mA and 0-10V

The 4-20mA signal is commonly used in industrial automation and process control for transmitting sensor data over long distances with high noise immunity. The 0-10V signal is often employed in building automation systems and lighting controls where short-distance, low-power signaling is sufficient. Your choice between 4-20mA and 0-10V should depend on the application's environmental conditions and accuracy requirements.

Compatibility and Interfacing Issues

4-20mA signals offer robust compatibility with long-distance transmission and noisy industrial environments due to current loop immunity to voltage drops, whereas 0-10V signals are more susceptible to signal degradation and require careful wire management. Interfacing 4-20mA devices typically involves current loop receivers or transmitters that ensure precise detection, while 0-10V signals need high-impedance inputs to prevent loading effects that can distort voltage levels. Systems integrating both standards often require signal converters or specialized input modules to maintain accurate data exchange and prevent compatibility conflicts.

Choosing the Right Signal Standard for Your Application

Choosing the right signal standard for your application depends on factors like noise immunity, distance, and compatibility. The 4-20mA current loop offers superior noise resistance and reliable data transmission over long distances, making it ideal for industrial environments. In contrast, 0-10V signals are simpler and cost-effective for short-range, low-interference applications, ensuring your system operates efficiently based on specific requirements.

4-20mA vs 0-10V Infographic

electrown.com

electrown.com