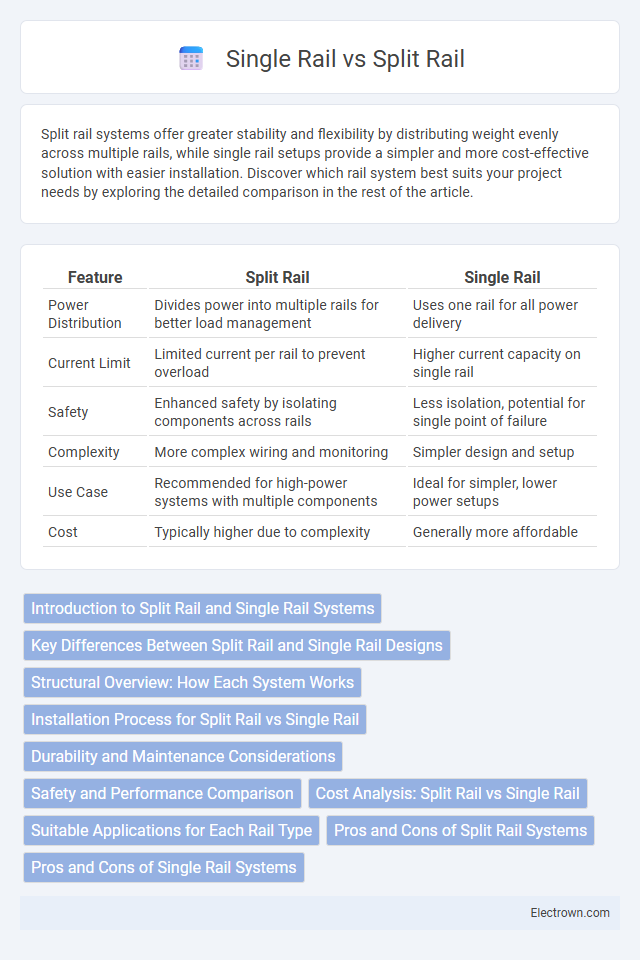

Split rail systems offer greater stability and flexibility by distributing weight evenly across multiple rails, while single rail setups provide a simpler and more cost-effective solution with easier installation. Discover which rail system best suits your project needs by exploring the detailed comparison in the rest of the article.

Table of Comparison

| Feature | Split Rail | Single Rail |

|---|---|---|

| Power Distribution | Divides power into multiple rails for better load management | Uses one rail for all power delivery |

| Current Limit | Limited current per rail to prevent overload | Higher current capacity on single rail |

| Safety | Enhanced safety by isolating components across rails | Less isolation, potential for single point of failure |

| Complexity | More complex wiring and monitoring | Simpler design and setup |

| Use Case | Recommended for high-power systems with multiple components | Ideal for simpler, lower power setups |

| Cost | Typically higher due to complexity | Generally more affordable |

Introduction to Split Rail and Single Rail Systems

Split rail systems divide power delivery into separate rails, each dedicated to a specific voltage or function, enhancing stability and reducing electrical noise. Single rail systems provide all power through one rail, simplifying installation but potentially increasing the risk of overload and voltage drops. Understanding the distinctions helps you choose a power supply configuration that best suits your hardware requirements and system reliability.

Key Differences Between Split Rail and Single Rail Designs

Split rail designs feature two or more parallel rails that distribute load across multiple points, enhancing stability and weight capacity, whereas single rail systems rely on one continuous rail that offers simplicity and a sleek appearance but may have lower load tolerance. Split rail configurations often allow for more flexible installation and better vibration management, making them ideal for heavy-duty applications, while single rail setups prioritize minimalism and ease of maintenance. Your choice between split rail and single rail should consider the specific load requirements, installation complexity, and aesthetic preferences of your project.

Structural Overview: How Each System Works

Split rail systems consist of multiple rails laid parallel, distributing weight and providing greater stability through interconnected support points, ideal for heavy-duty applications. Single rail systems rely on a solitary rail to bear the entire load, offering simpler installation and reduced material costs but requiring higher precision in alignment for structural integrity. The choice between split rail and single rail depends on load distribution needs, installation environment, and maintenance considerations.

Installation Process for Split Rail vs Single Rail

The installation process for split rail fencing involves setting posts at regular intervals and attaching horizontal rails, which allows for straightforward assembly and flexibility in uneven terrain. Single rail fencing typically requires fewer materials but demands precise alignment and secure fastening of longer rails to prevent sagging, making installation slightly more labor-intensive. Your choice depends on the desired aesthetic and the terrain, as split rail systems offer easier adaptability during setup compared to single rail fences.

Durability and Maintenance Considerations

Split rail fences typically offer greater durability due to their thicker, sturdier wooden posts and rails, which resist weathering and physical damage more effectively than single rail fences. Maintenance for split rail fences involves periodic staining or sealing to protect against rot and insect damage, whereas single rail fences require more frequent inspections and repairs due to their thinner rails being more susceptible to cracking or warping. Choosing split rail fencing reduces long-term upkeep costs and improves lifespan, especially in environments prone to harsh weather conditions.

Safety and Performance Comparison

Split rail systems enhance safety by distributing electrical current more evenly, reducing the risk of overheating and electrical faults compared to single rail designs. Performance in split rail configurations typically excels due to improved voltage stability and lower resistance, which supports higher power demands reliably. Single rail setups may offer simpler installation but often sacrifice long-term efficiency and overall safety under heavy load conditions.

Cost Analysis: Split Rail vs Single Rail

Split rail fencing typically costs less per linear foot than single rail fencing due to its simpler construction and use of fewer materials, making it a budget-friendly option for large properties. Single rail fencing offers a sleeker, more modern aesthetic but involves higher costs related to increased material usage and more precise installation requirements. Evaluating fence longevity and maintenance expenses is crucial; although split rail may require more upkeep, its initial affordability often outweighs these factors in cost analysis.

Suitable Applications for Each Rail Type

Split rails are ideal for agricultural fencing, livestock containment, and rural properties due to their rustic appearance and ability to cover long distances with minimal materials. Single rails suit urban landscaping, gardens, and decorative boundaries where a clean, minimalist look and precise alignment are essential. Your choice depends on the balance between aesthetic appeal and functional requirements for specific environments.

Pros and Cons of Split Rail Systems

Split rail systems offer enhanced stability by distributing loads across multiple rails, improving structural integrity for heavy-duty applications. They allow for easier maintenance and repair since individual rails can be replaced without disrupting the entire track, reducing downtime. However, split rail systems involve higher installation costs and require more precise alignment to prevent operational issues, which can increase initial setup complexity.

Pros and Cons of Single Rail Systems

Single rail systems offer streamlined installation and a cleaner aesthetic by consolidating components into one rail, which can simplify maintenance and reduce overall space requirements. However, they might present limitations in weight distribution and load capacity compared to split rail systems, potentially affecting stability in heavy-duty applications. Your choice should consider the balance between these efficiency benefits and the structural demands of your specific project.

Split rail vs single rail Infographic

electrown.com

electrown.com