Breadboards offer a reusable and solder-free platform for quickly prototyping electronic circuits, making them ideal for testing and iterative design. Perfboards provide a more permanent solution by allowing components to be soldered securely, ensuring durability and stability for your final projects; explore the rest of the article to discover which option best suits your needs.

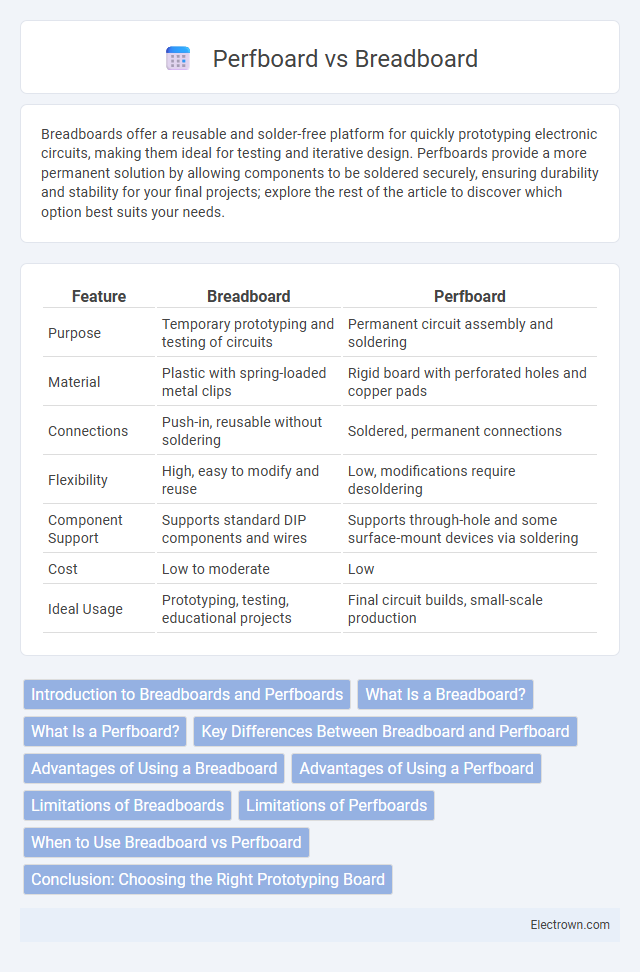

Table of Comparison

| Feature | Breadboard | Perfboard |

|---|---|---|

| Purpose | Temporary prototyping and testing of circuits | Permanent circuit assembly and soldering |

| Material | Plastic with spring-loaded metal clips | Rigid board with perforated holes and copper pads |

| Connections | Push-in, reusable without soldering | Soldered, permanent connections |

| Flexibility | High, easy to modify and reuse | Low, modifications require desoldering |

| Component Support | Supports standard DIP components and wires | Supports through-hole and some surface-mount devices via soldering |

| Cost | Low to moderate | Low |

| Ideal Usage | Prototyping, testing, educational projects | Final circuit builds, small-scale production |

Introduction to Breadboards and Perfboards

Breadboards provide a reusable platform for prototyping electronic circuits with easy insertion and removal of components, ideal for testing and development phases. Perfboards consist of a grid of pre-drilled holes with copper pads, designed for permanent soldered connections to create durable circuit assemblies. Your choice depends on whether you need a temporary setup for experimentation or a robust solution for finalizing a circuit design.

What Is a Breadboard?

A breadboard is a reusable platform used for prototyping electronic circuits without soldering, featuring a grid of interconnected holes that allow components and wires to be easily inserted and rearranged. It enables quick testing and modification of circuit designs, making it ideal for experimentation and learning. Your projects can benefit from the flexibility and convenience breadboards offer compared to permanent soldered solutions like perfboards.

What Is a Perfboard?

Perfboard is a type of prototyping board used for constructing electronic circuits by soldering components directly onto a grid of pre-drilled holes with copper pads. Unlike breadboards, which allow for temporary connections without soldering, perfboards provide a permanent solution for circuit assembly and durability. You can customize perfboards by cutting tracks or adding wires, making them ideal for finalizing and testing complex circuit designs.

Key Differences Between Breadboard and Perfboard

Breadboards feature reusable, solderless connections ideal for rapid prototyping and easy circuit modifications, while perfboards require permanent soldered joints, offering durability for finalized projects. Breadboards consist of interconnected spring clips under a perforated plastic surface, enabling temporary component placement without soldering; perfboards are constructed with a grid of isolated holes, each surrounded by copper pads for soldering individual components. Perfboards provide superior mechanical stability and reliable long-term connections compared to the non-permanent, flexible nature of breadboards often used in testing and development phases.

Advantages of Using a Breadboard

Breadboards provide a reusable and solder-free platform for prototyping electronic circuits, allowing fast and easy component insertion and removal. Their grid of interconnected spring clips enables flexible circuit modifications without permanent connections, making them ideal for iterative design and testing. Breadboards support a wide range of components and reduce the risk of damage from overheating, which is common during soldering on perfboards.

Advantages of Using a Perfboard

Perfboard offers a durable and permanent solution for electronic circuit construction, providing stable mechanical support and reliable electrical connections through soldered joints. It allows for compact and organized layouts, ideal for prototyping or small production runs where circuit modification is infrequent. The consistent hole spacing accommodates standard component leads and simplifies the integration of custom wiring pathways.

Limitations of Breadboards

Breadboards are ideal for prototyping but have limitations such as lower current capacity, which restricts their use in high-power circuits. Their spring contacts can become unreliable over time, leading to poor electrical connections. Your projects requiring durable and permanent soldered joints are better suited for perfboards, which offer enhanced stability and long-term reliability.

Limitations of Perfboards

Perfboards offer a durable platform for soldering components but lack the flexibility of easy circuit modifications due to their fixed hole patterns and absence of pre-routed connections. Troubleshooting and making design changes on perfboards is time-consuming since each connection requires manual soldering, increasing the risk of solder bridges and component damage. Their rigidity limits prototyping speed and adaptability compared to breadboards, which provide reusable and flexible electrical connections without permanent assembly.

When to Use Breadboard vs Perfboard

Breadboards are ideal for prototyping and testing circuits because they allow easy insertion and removal of components without soldering, making them perfect for iterative development and troubleshooting. Perfboards are better suited for finalized projects where a more permanent, durable connection is required, as components are soldered in place to ensure stability and reliability. Choose breadboards during the design phase and switch to perfboards when ready to build a long-term, robust prototype or small production run.

Conclusion: Choosing the Right Prototyping Board

Choosing the right prototyping board depends on your project's complexity and permanence requirements. Breadboards offer reusable, solderless connections ideal for quick testing and iterative designs, while perfboards provide durable, soldered circuits suited for final prototypes or long-term use. Your decision should align with whether you need flexibility during development or a stable, permanent solution for your electronics project.

Breadboard vs Perfboard Infographic

electrown.com

electrown.com