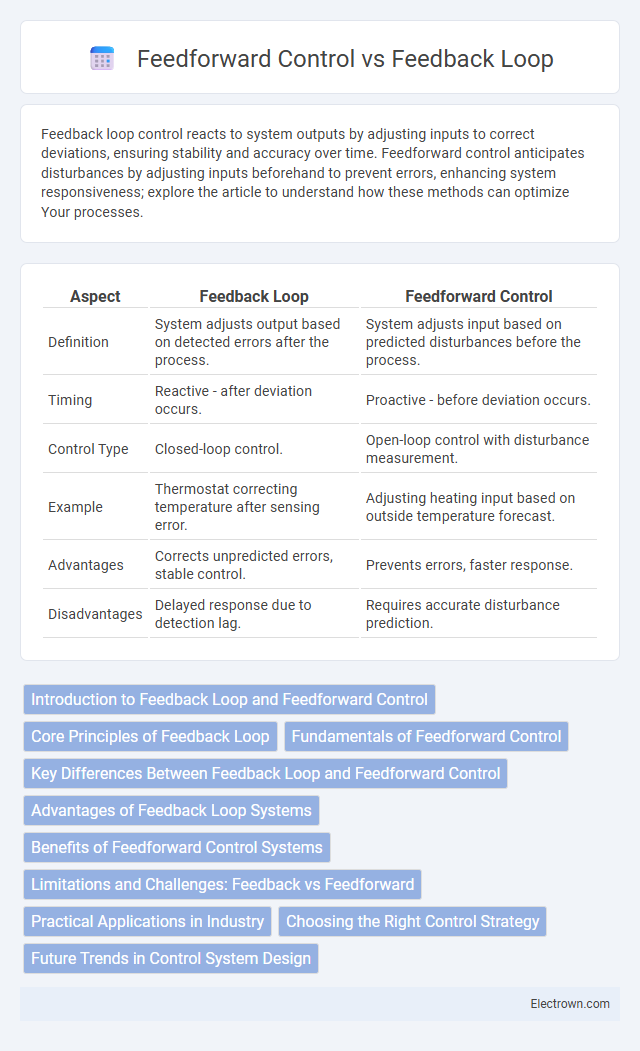

Feedback loop control reacts to system outputs by adjusting inputs to correct deviations, ensuring stability and accuracy over time. Feedforward control anticipates disturbances by adjusting inputs beforehand to prevent errors, enhancing system responsiveness; explore the article to understand how these methods can optimize Your processes.

Table of Comparison

| Aspect | Feedback Loop | Feedforward Control |

|---|---|---|

| Definition | System adjusts output based on detected errors after the process. | System adjusts input based on predicted disturbances before the process. |

| Timing | Reactive - after deviation occurs. | Proactive - before deviation occurs. |

| Control Type | Closed-loop control. | Open-loop control with disturbance measurement. |

| Example | Thermostat correcting temperature after sensing error. | Adjusting heating input based on outside temperature forecast. |

| Advantages | Corrects unpredicted errors, stable control. | Prevents errors, faster response. |

| Disadvantages | Delayed response due to detection lag. | Requires accurate disturbance prediction. |

Introduction to Feedback Loop and Feedforward Control

Feedback loop is a control system mechanism that continuously monitors output signals to make real-time adjustments, ensuring system stability and accuracy. Feedforward control anticipates disturbances by measuring inputs before they affect the process, enabling proactive corrective actions that prevent errors. Both methods enhance system performance but differ in timing and approach to handling variability.

Core Principles of Feedback Loop

Feedback loop control operates on the principle of continuously monitoring system output to compare it with a desired setpoint, enabling automatic adjustments to correct deviations and maintain stability. It relies on real-time error detection by measuring the difference between actual and target values, then using this error signal to influence corrective actions. This dynamic process ensures adaptive response and system regulation within various control environments such as engineering, biology, and economics.

Fundamentals of Feedforward Control

Feedforward control anticipates disturbances by measuring input variables and adjusting the system before output deviations occur, enhancing process stability and response time. This control strategy relies on predictive models and sensor data to proactively maintain desired performance, reducing the lag inherent in feedback loops. Understanding feedforward control fundamentals helps you optimize system efficiency by preventing errors rather than correcting them after they happen.

Key Differences Between Feedback Loop and Feedforward Control

Feedback loop control relies on monitoring output to make adjustments, correcting errors after they occur, while feedforward control anticipates disturbances by adjusting inputs proactively before any deviation happens. Feedback loops are reactive, dependent on sensor data to maintain system stability, whereas feedforward control is predictive, utilizing models or external information to prevent errors. Understanding these distinctions helps enhance your system's efficiency by choosing the appropriate control strategy based on response time and disturbance predictability.

Advantages of Feedback Loop Systems

Feedback loop systems offer significant advantages by continuously monitoring and adjusting outputs based on real-time data, ensuring greater accuracy and stability in dynamic environments. Their ability to correct deviations from desired performance enhances system reliability and adaptability, making them ideal for complex processes. You benefit from improved error detection and correction, which reduces variability and enhances overall system efficiency.

Benefits of Feedforward Control Systems

Feedforward control systems enhance process efficiency by predicting disturbances and implementing corrective actions before deviations occur, reducing lag time and improving stability. These systems minimize the need for reactive adjustments, leading to decreased system wear and enhanced overall performance. Industries benefit from feedforward control through optimized resource utilization, increased reliability, and improved product quality.

Limitations and Challenges: Feedback vs Feedforward

Feedback control often faces limitations such as delayed response due to its reliance on error detection after system output, which can result in instability or oscillations in dynamic environments. Feedforward control challenges include the need for precise modeling of system dynamics and external disturbances, making it less robust to unexpected changes or unmodeled variables. Both approaches require careful calibration, where feedback compensates for inaccuracies in feedforward, while reliance solely on feedforward risks inadequate correction, especially in complex or nonlinear systems.

Practical Applications in Industry

Feedback loop control is commonly used in temperature regulation systems within manufacturing plants to maintain consistent product quality by continuously adjusting based on real-time measurements. Feedforward control is integral in chemical processing industries to anticipate disturbances such as raw material variation, enabling preemptive adjustments for optimal reaction conditions. Both control methods enhance process stability and efficiency, with feedback loops correcting deviations after they occur and feedforward systems preventing deviations before they impact the process.

Choosing the Right Control Strategy

Choosing the right control strategy depends on the nature of your system and desired outcomes. Feedback loop control excels in correcting errors after they occur by continuously monitoring output, making it ideal for systems with unpredictable disturbances. Feedforward control anticipates changes by adjusting inputs based on external variables, providing proactive adjustments for processes with measurable and consistent influencers.

Future Trends in Control System Design

Future trends in control system design emphasize advanced feedforward control integrating artificial intelligence and machine learning to predict and mitigate disturbances before they occur, enhancing system response and efficiency. Feedback loops are increasingly combined with adaptive algorithms to enable real-time adjustments and improve robustness in complex, nonlinear environments. Emerging technologies prioritize hybrid control architectures that leverage predictive analytics and data-driven modeling to optimize performance in sectors such as autonomous vehicles, smart grids, and industrial automation.

Feedback Loop vs Feedforward Control Infographic

electrown.com

electrown.com