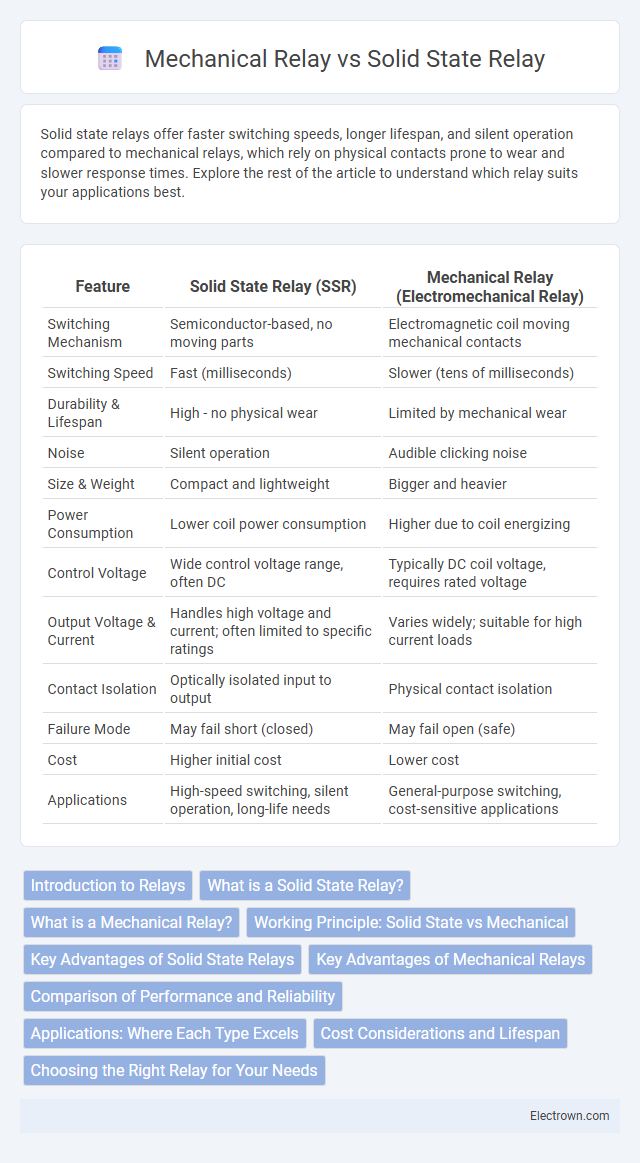

Solid state relays offer faster switching speeds, longer lifespan, and silent operation compared to mechanical relays, which rely on physical contacts prone to wear and slower response times. Explore the rest of the article to understand which relay suits your applications best.

Table of Comparison

| Feature | Solid State Relay (SSR) | Mechanical Relay (Electromechanical Relay) |

|---|---|---|

| Switching Mechanism | Semiconductor-based, no moving parts | Electromagnetic coil moving mechanical contacts |

| Switching Speed | Fast (milliseconds) | Slower (tens of milliseconds) |

| Durability & Lifespan | High - no physical wear | Limited by mechanical wear |

| Noise | Silent operation | Audible clicking noise |

| Size & Weight | Compact and lightweight | Bigger and heavier |

| Power Consumption | Lower coil power consumption | Higher due to coil energizing |

| Control Voltage | Wide control voltage range, often DC | Typically DC coil voltage, requires rated voltage |

| Output Voltage & Current | Handles high voltage and current; often limited to specific ratings | Varies widely; suitable for high current loads |

| Contact Isolation | Optically isolated input to output | Physical contact isolation |

| Failure Mode | May fail short (closed) | May fail open (safe) |

| Cost | Higher initial cost | Lower cost |

| Applications | High-speed switching, silent operation, long-life needs | General-purpose switching, cost-sensitive applications |

Introduction to Relays

Relays are essential electromechanical or solid-state devices used for switching electrical circuits by a low-power signal. Mechanical relays employ physical moving contacts to open or close circuits, providing electrical isolation and handling high current loads. Solid State Relays (SSRs) use semiconductor components for switching, offering faster response times, longer lifespan, and reduced electromagnetic interference compared to mechanical relays.

What is a Solid State Relay?

A Solid State Relay (SSR) is an electronic switching device that uses semiconductor components to switch electrical loads without moving parts, providing faster response times and longer lifespan compared to Mechanical Relays. SSRs offer silent operation, resistance to shock and vibration, and precise control, making them ideal for automation and industrial applications where reliability and durability are critical. Your choice of SSR over a Mechanical Relay can enhance system performance in environments requiring frequent switching and reduced maintenance.

What is a Mechanical Relay?

A mechanical relay is an electromechanical switch that uses a physical moving armature to open or close electrical contacts in response to an input signal. It operates by energizing a coil, which creates a magnetic field that moves the armature, enabling the transfer or interruption of current in the controlled circuit. Mechanical relays are commonly used for their ability to handle high voltage and current loads with galvanic isolation between control and output circuits.

Working Principle: Solid State vs Mechanical

Solid State Relays operate by using semiconductor components to switch electrical signals without moving parts, offering silent and faster switching with enhanced durability. Mechanical Relays rely on an electromagnetic coil to physically move contacts, creating a mechanical connection that can wear out over time and generate audible clicks. Your choice depends on whether you prioritize longevity and speed (Solid State) or cost-effectiveness and simplicity (Mechanical).

Key Advantages of Solid State Relays

Solid State Relays (SSRs) offer faster switching speeds and longer operational lifespans compared to Mechanical Relays due to the absence of moving parts. SSRs provide superior resistance to shock and vibration, enhancing reliability in harsh environments. Their silent operation, low power consumption, and precise electronic control make SSRs ideal for applications requiring high-speed and noise-free switching.

Key Advantages of Mechanical Relays

Mechanical relays offer key advantages such as their ability to handle high current loads and provide electrical isolation with minimal leakage current. They are known for their robustness in harsh environments and superior performance in switching inductive loads without generating electrical noise. Your choice of a mechanical relay ensures reliable operation in applications requiring physical contact-based switching and straightforward troubleshooting.

Comparison of Performance and Reliability

Solid State Relays (SSRs) offer faster switching speeds, longer lifespan, and greater resistance to shock and vibration compared to Mechanical Relays, which rely on physical contacts that wear out over time. SSRs provide silent operation and reduced electromagnetic interference, enhancing overall system reliability, while Mechanical Relays are more prone to contact degradation and mechanical failure under frequent switching. Your choice between the two should consider the application's performance demands and maintenance requirements for optimal reliability.

Applications: Where Each Type Excels

Solid State Relays excel in applications requiring silent operation, high-speed switching, and long lifespan, making them ideal for industrial automation, HVAC systems, and electronic control devices. Mechanical Relays are preferred in high-current or high-voltage applications, such as automotive, power distribution, and heavy machinery, where physical isolation and robustness are critical. Your choice between these relays depends on the specific demands of switching speed, noise tolerance, and electrical load in your application.

Cost Considerations and Lifespan

Solid State Relays (SSRs) generally have a higher upfront cost compared to Mechanical Relays but offer a significantly longer lifespan due to the absence of moving parts, reducing maintenance expenses. Mechanical Relays are more cost-effective initially but tend to wear out faster from physical contacts, leading to frequent replacements and increased long-term costs. Your choice should balance initial budget constraints against durability requirements to optimize overall cost efficiency.

Choosing the Right Relay for Your Needs

Solid State Relays (SSRs) offer fast switching speeds, silent operation, and longer lifespan with no moving parts, making them ideal for applications requiring frequent switching and high reliability. Mechanical Relays provide robust performance and are often preferred for high-load or high-voltage environments due to their physical contact mechanism, which can handle surge currents better. Assess Your specific requirements for switching speed, load type, and durability to determine whether a Solid State Relay or Mechanical Relay best suits Your needs.

Solid State Relay vs Mechanical Relay Infographic

electrown.com

electrown.com