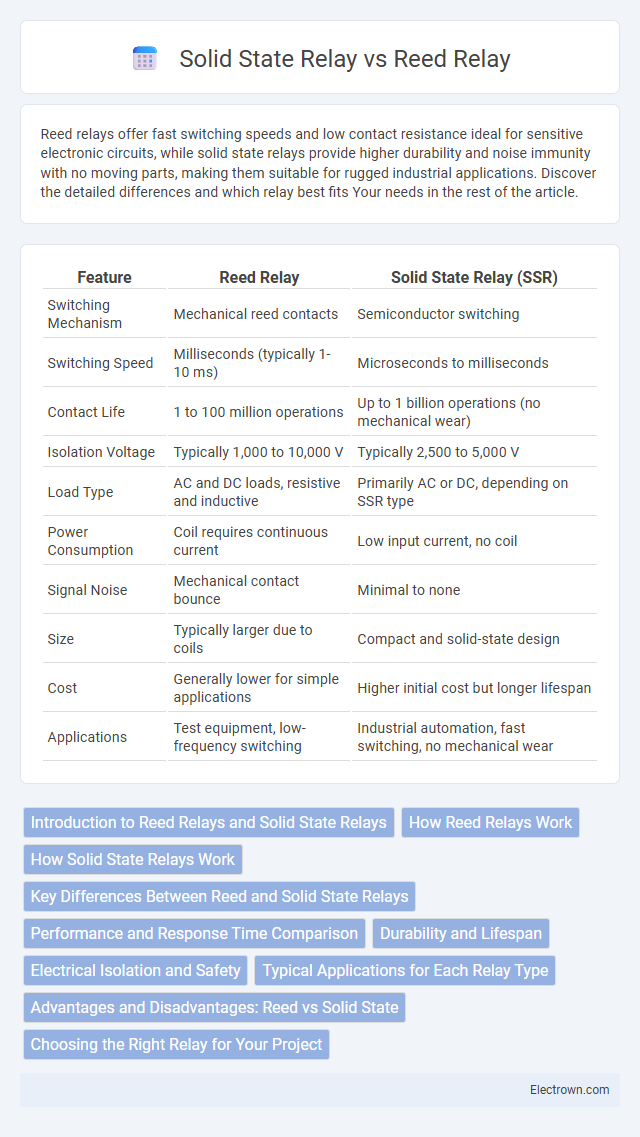

Reed relays offer fast switching speeds and low contact resistance ideal for sensitive electronic circuits, while solid state relays provide higher durability and noise immunity with no moving parts, making them suitable for rugged industrial applications. Discover the detailed differences and which relay best fits Your needs in the rest of the article.

Table of Comparison

| Feature | Reed Relay | Solid State Relay (SSR) |

|---|---|---|

| Switching Mechanism | Mechanical reed contacts | Semiconductor switching |

| Switching Speed | Milliseconds (typically 1-10 ms) | Microseconds to milliseconds |

| Contact Life | 1 to 100 million operations | Up to 1 billion operations (no mechanical wear) |

| Isolation Voltage | Typically 1,000 to 10,000 V | Typically 2,500 to 5,000 V |

| Load Type | AC and DC loads, resistive and inductive | Primarily AC or DC, depending on SSR type |

| Power Consumption | Coil requires continuous current | Low input current, no coil |

| Signal Noise | Mechanical contact bounce | Minimal to none |

| Size | Typically larger due to coils | Compact and solid-state design |

| Cost | Generally lower for simple applications | Higher initial cost but longer lifespan |

| Applications | Test equipment, low-frequency switching | Industrial automation, fast switching, no mechanical wear |

Introduction to Reed Relays and Solid State Relays

Reed relays consist of thin, ferromagnetic reeds sealed in a glass tube that close when an electromagnetic coil is energized, offering fast switching and excellent isolation. Solid state relays use semiconductor devices like thyristors or transistors to switch loads without moving parts, providing longer lifespan and silent operation. Your choice between reed relays and solid state relays depends on factors such as switching speed, durability, and electrical noise sensitivity.

How Reed Relays Work

Reed relays operate by using an electromagnetic coil to control a pair of ferromagnetic reeds that close or open a circuit through magnetic attraction, providing fast switching with low contact resistance. Their hermetically sealed contacts ensure high reliability and are ideal for sensitive signal switching in precision measurement applications. You benefit from their minimal power consumption and excellent isolation compared to solid state relays, which rely on semiconductor components rather than mechanical contacts.

How Solid State Relays Work

Solid State Relays (SSRs) operate by using semiconductor components such as thyristors, triacs, or transistors to switch electrical loads without moving parts, ensuring silent and rapid switching. When a control signal is applied, an LED inside the SSR activates a photodiode or phototransistor, providing electrical isolation and allowing current to flow through the load circuit safely. Your choice between Reed relays and SSRs depends on factors like switching speed, durability, and noise sensitivity, with SSRs offering longer life and faster performance in most applications.

Key Differences Between Reed and Solid State Relays

Reed relays use magnetic fields to open and close contacts within a sealed glass envelope, offering fast switching speeds and electrical isolation, while solid state relays rely on semiconductor components for switching, providing no moving parts and higher durability. Reed relays excel in low current, low voltage applications with minimal contact resistance, whereas solid state relays are preferred for high current, high voltage loads with silent operation and enhanced resistance to shock and vibration. Your choice depends on factors like switching speed, load type, isolation requirements, and reliability under mechanical stress.

Performance and Response Time Comparison

Reed relays offer extremely fast switching times typically in the range of 0.5 to 2 milliseconds with very low contact resistance, making them ideal for high-precision applications requiring low signal distortion. Solid state relays (SSRs) provide faster response times often below 1 millisecond and superior durability due to the absence of moving parts, suitable for high-frequency switching and noisy environments. Performance-wise, reed relays excel in low current signal switching with minimal leakage, whereas SSRs deliver better performance under high load currents with longer operational lifespans and zero contact bounce.

Durability and Lifespan

Reed relays offer exceptional durability with a lifespan typically exceeding 10 million operations due to their sealed construction, which protects contacts from contamination. Solid state relays (SSRs) provide even longer lifespans by eliminating mechanical wear, allowing them to perform millions to billions of switching cycles under optimal thermal conditions. When selecting a relay, consider your application's switching frequency and environmental factors to ensure the most reliable and durable choice for your system.

Electrical Isolation and Safety

Reed relays provide superior electrical isolation due to their hermetically sealed contacts, preventing electrical noise and ensuring reliable operation in sensitive circuits. Solid state relays, while offering fast switching and longer life, use semiconductor components that provide galvanic isolation through optocouplers, but this isolation may be less robust under high voltage spikes. Your choice should prioritize reed relays for maximum safety in high-voltage and noise-sensitive environments, while solid state relays suit applications requiring durability and rapid switching.

Typical Applications for Each Relay Type

Reed relays are commonly used in low-power signal switching applications such as telecommunications, test equipment, and medical devices due to their fast switching speed and low contact resistance. Solid state relays excel in industrial automation, motor control, and HVAC systems where high current handling, electrical isolation, and long operational life are crucial. Selecting the right relay depends on your specific application requirements, including load type, switching speed, and environmental conditions.

Advantages and Disadvantages: Reed vs Solid State

Reed relays offer advantages such as low contact resistance, fast switching speed, and excellent isolation, but they suffer from limited current capacity and mechanical wear over time. Solid state relays provide high durability, silent operation, and better suitability for high-frequency switching, although they may have higher on-state resistance and potential issues with thermal management. Choosing between reed and solid state relays depends on specific application requirements like current load, switching speed, and longevity.

Choosing the Right Relay for Your Project

Choosing the right relay for your project depends on factors like switching speed, load type, and reliability. Reed relays offer fast switching and excellent isolation, ideal for low-current applications and sensitive signal switching. Solid state relays provide higher load capacity, longer lifespan, and no mechanical wear, making them suitable for industrial automation and high-power loads.

Reed relay vs Solid state relay Infographic

electrown.com

electrown.com